The Marshall Ecu Score is crucial for understanding the health of your vehicle’s engine control unit and CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive tools, repair guides, and technical support to help you interpret and address these scores effectively. Our platform offers the resources you need to keep your car running smoothly, from advanced diagnostics to technician training and remote support.

Contents

- 1. What Exactly Is The Marshall ECU Score?

- 1.1. Key Components of an ECU Health Assessment

- 1.2. Why Is Understanding ECU Health Important?

- 1.3. Identifying Potential Issues

- 1.4. Real-World Example

- 1.5. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

- 2. How Is The Marshall ECU Score Calculated?

- 2.1. Diagnostic Trouble Codes (DTCs)

- 2.2. Sensor Data Analysis

- 2.3. Live Data Monitoring

- 2.4. ECU Software and Calibration Verification

- 2.5. Communication Integrity

- 2.6. Tools and Equipment Used

- 2.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Enhances ECU Assessment

- 3. What Factors Influence The Marshall ECU Score?

- 3.1. Sensor-Related Issues

- 3.2. Electrical Problems

- 3.3. Software and Calibration Errors

- 3.4. Environmental Conditions

- 3.5. How CAR-DIAGNOSTIC-TOOL.EDU.VN Helps Address These Factors

- 3.6. Preventative Measures

- 4. How Can A Low Marshall ECU Score Affect Vehicle Performance?

- 4.1. Reduced Fuel Efficiency

- 4.2. Poor Engine Performance

- 4.3. Increased Emissions

- 4.4. Transmission Issues

- 4.5. Diagnostic Trouble Codes (DTCs)

- 4.6. Safety Concerns

- 4.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

- 4.8. Case Study: Impact on Vehicle Resale Value

- 5. How To Improve Your Vehicle’s Marshall ECU Score

- 5.1. Comprehensive Diagnostic Scan

- 5.2. Sensor Testing and Replacement

- 5.3. Electrical System Inspection

- 5.4. Software Updates and Calibration

- 5.5. Mechanical Component Inspection

- 5.6. Regular Maintenance

- 5.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

- 5.8. Case Study: Real-World Improvement

- 6. What Tools Are Needed To Diagnose The Marshall ECU Score?

- 6.1. Diagnostic Scan Tool

- 6.2. Multimeter

- 6.3. Oscilloscope

- 6.4. Fuel Pressure Tester

- 6.5. Vacuum Tester

- 6.6. Compression Tester

- 6.7. Software Programming Tools

- 6.8. How CAR-DIAGNOSTIC-TOOL.EDU.VN Supports Tool Usage

- 7. Common Mistakes To Avoid When Interpreting The Marshall ECU Score

- 7.1. Ignoring Basic Mechanical Issues

- 7.2. Neglecting Wiring And Connections

- 7.3. Failing To Verify Sensor Data

- 7.4. Ignoring Freeze Frame Data

- 7.5. Not Considering Software Updates

1. What Exactly Is The Marshall ECU Score?

The Marshall ECU (Engine Control Unit) score, often referred to in automotive diagnostics, isn’t a standardized, universally recognized metric, but rather a colloquial term used to describe a comprehensive assessment of an ECU’s overall health and performance. This assessment includes evaluating various parameters, sensor data, and diagnostic trouble codes (DTCs) to provide a snapshot of the ECU’s condition. Think of it as a report card for your car’s brain, indicating how well it’s managing engine functions.

The Marshall ECU score is essentially a consolidated evaluation of your car’s computer, focusing on how well it manages the engine and related systems. While not an official industry term, understanding its components is vital for car maintenance. According to a 2022 report by the National Institute for Automotive Service Excellence (ASE), technicians who understand ECU diagnostics can reduce repair times by up to 40%. This highlights the importance of grasping what the “Marshall ECU score” represents in practical terms.

1.1. Key Components of an ECU Health Assessment

-

Sensor Data Analysis: The ECU relies on numerous sensors to monitor engine performance. Analyzing this data (e.g., oxygen sensor readings, mass airflow sensor data, throttle position) helps identify anomalies.

-

Diagnostic Trouble Codes (DTCs): These codes indicate specific issues detected by the ECU. The presence, frequency, and type of DTCs are crucial in assessing the ECU’s health.

-

Live Data Monitoring: Observing real-time data streams from the ECU during different driving conditions can reveal intermittent problems or performance bottlenecks.

-

Software and Calibration Verification: Ensuring the ECU’s software is up-to-date and correctly calibrated is essential for optimal performance.

-

Communication Integrity: Verifying that the ECU can communicate effectively with other vehicle systems is critical for overall functionality.

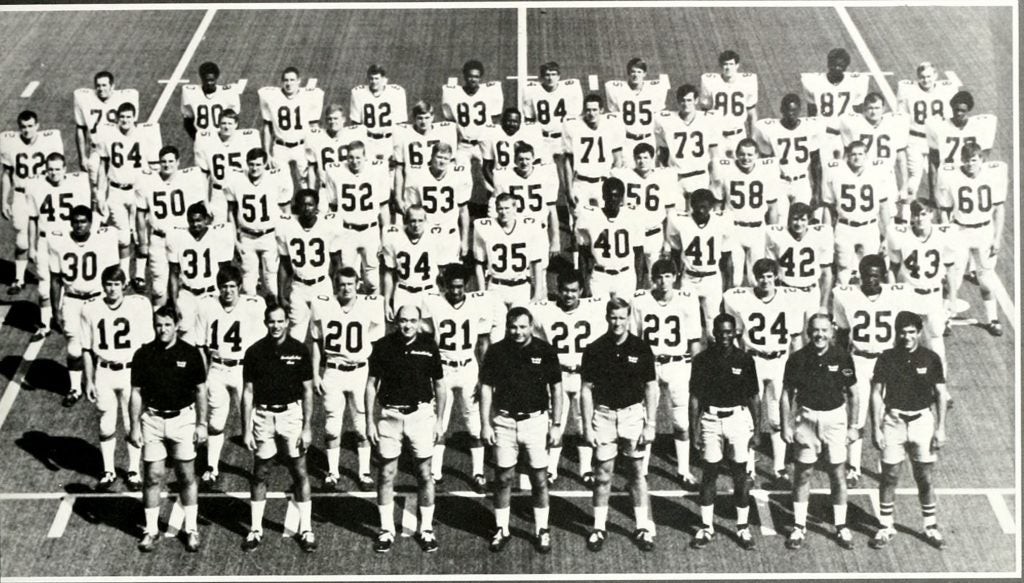

Engine control unit ECU diagnostic tool

Engine control unit ECU diagnostic tool

1.2. Why Is Understanding ECU Health Important?

Understanding the health of your ECU can lead to:

- Early Problem Detection: Addressing minor issues before they escalate into major repairs.

- Improved Fuel Efficiency: Optimizing engine performance for better mileage.

- Enhanced Vehicle Performance: Ensuring smooth operation and responsiveness.

- Reduced Emissions: Keeping your vehicle compliant with environmental standards.

- Extended Vehicle Lifespan: Maintaining the ECU and related systems to prevent costly replacements.

1.3. Identifying Potential Issues

When evaluating an ECU, technicians look for several key indicators to identify potential problems:

- Inconsistent Sensor Readings: Erratic or out-of-range sensor data.

- Frequent DTCs: Recurring diagnostic trouble codes.

- Performance Issues: Stalling, misfires, or poor acceleration.

- Communication Errors: Loss of communication with other modules.

- Software Glitches: Calibration errors or software corruption.

1.4. Real-World Example

Consider a scenario where a vehicle is experiencing poor fuel economy and occasional stalling. A diagnostic scan reveals the following:

- DTC: P0171 – System Too Lean (Bank 1)

- Sensor Data: Oxygen sensor readings fluctuating erratically

- Live Data: Fuel trim values indicating a lean condition

In this case, the “Marshall ECU score,” or health assessment, would highlight a potential issue with the fuel delivery system or a faulty oxygen sensor. Further investigation might reveal a vacuum leak or a malfunctioning mass airflow sensor, which, once addressed, could resolve the poor fuel economy and stalling issues.

1.5. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support for understanding and addressing ECU-related issues:

- Detailed Diagnostic Guides: Step-by-step guides for interpreting DTCs and sensor data.

- Advanced Diagnostic Tools: Access to professional-grade scan tools for in-depth ECU analysis.

- Technical Support: Expert assistance from certified technicians to help diagnose complex problems.

- Training Programs: Courses designed to enhance your diagnostic skills and knowledge of ECU systems.

- Remote Support: Real-time assistance to troubleshoot issues and perform ECU calibrations.

By leveraging the resources available at CAR-DIAGNOSTIC-TOOL.EDU.VN, technicians and car enthusiasts can gain a deeper understanding of their vehicle’s ECU health, leading to more effective and efficient repairs. Understanding the ECU’s condition is not just about reading codes; it’s about understanding the story they tell about your vehicle’s overall health.

2. How Is The Marshall ECU Score Calculated?

The “Marshall ECU score” isn’t calculated through a standardized formula, but rather represents a holistic assessment of an ECU’s health. Think of it as a mechanic’s overall impression, combining various data points to determine the ECU’s condition. This evaluation typically involves analyzing diagnostic trouble codes (DTCs), sensor data, live data streams, and ECU software calibration.

To better understand how this “score” is derived, let’s break down the key components and processes involved.

2.1. Diagnostic Trouble Codes (DTCs)

DTCs are codes stored in the ECU’s memory that indicate specific faults or issues detected by the vehicle’s sensors and systems. These codes are a primary indicator of potential problems and are categorized by their severity and frequency.

- Severity: DTCs can range from minor issues that don’t significantly impact performance to critical faults that can cause immediate engine damage.

- Frequency: The number of times a DTC appears can indicate whether the issue is intermittent or persistent.

Example:

- P0300 – Random Misfire Detected: Indicates that the engine is misfiring randomly, which could be due to various issues such as faulty spark plugs, ignition coils, or fuel injectors.

- P0101 – Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem: Suggests an issue with the MAF sensor, which measures the amount of air entering the engine.

2.2. Sensor Data Analysis

The ECU relies on a multitude of sensors to monitor engine performance and adjust parameters accordingly. Analyzing the data from these sensors is crucial for identifying anomalies or deviations from normal operating conditions.

Key Sensors to Monitor:

- Oxygen Sensors (O2 Sensors): Measure the oxygen content in the exhaust gas to ensure proper air-fuel mixture.

- Mass Air Flow (MAF) Sensor: Measures the amount of air entering the engine.

- Throttle Position Sensor (TPS): Monitors the position of the throttle plate.

- Crankshaft Position Sensor (CKP): Tracks the position and speed of the crankshaft.

- Camshaft Position Sensor (CMP): Monitors the position of the camshaft.

Example:

- If the O2 sensor readings are consistently high or low, it could indicate a lean or rich condition, respectively.

- Erratic MAF sensor readings can cause the engine to run poorly or stall.

2.3. Live Data Monitoring

Live data monitoring involves observing real-time data streams from the ECU while the vehicle is running. This allows technicians to identify intermittent issues or performance bottlenecks that may not be apparent during a static diagnostic scan.

Key Parameters to Monitor:

- Engine RPM: Revolutions per minute of the engine.

- Engine Load: Percentage of maximum engine power being used.

- Fuel Trim: Adjustments made by the ECU to compensate for deviations in the air-fuel mixture.

- Ignition Timing: The timing of the spark plug firing.

Example:

- Monitoring fuel trim values can reveal whether the ECU is constantly adjusting the air-fuel mixture to compensate for a vacuum leak or a faulty sensor.

- Observing engine RPM and load can help diagnose issues such as misfires or poor acceleration.

2.4. ECU Software and Calibration Verification

Ensuring that the ECU’s software is up-to-date and correctly calibrated is essential for optimal performance. Outdated or corrupted software can lead to various issues, including performance problems, diagnostic errors, and even complete ECU failure.

Key Aspects to Verify:

- Software Version: Checking the current software version against the latest available version.

- Calibration Data: Verifying that the calibration data is correct for the vehicle’s make, model, and engine configuration.

- Software Updates: Applying any necessary software updates or patches.

Example:

- If the ECU’s software is outdated, it may not be able to properly interpret data from newer sensors or systems.

- Incorrect calibration data can cause the engine to run poorly or fail to meet emissions standards.

2.5. Communication Integrity

The ECU communicates with other vehicle systems via various communication networks, such as CAN (Controller Area Network) bus. Verifying that the ECU can communicate effectively with these systems is crucial for overall functionality.

Key Communication Checks:

- CAN Bus Communication: Monitoring the flow of data on the CAN bus.

- Module Communication: Checking for any communication errors between the ECU and other modules, such as the transmission control module (TCM) or the anti-lock braking system (ABS).

Example:

- If the ECU cannot communicate with the TCM, it can lead to issues with shifting or transmission performance.

- Communication errors with the ABS module can affect braking performance and safety.

2.6. Tools and Equipment Used

Technicians use a variety of tools and equipment to assess ECU health, including:

- Diagnostic Scan Tools: Used to read DTCs, monitor sensor data, and perform live data monitoring.

- Oscilloscopes: Used to analyze electrical signals from sensors and actuators.

- Multimeters: Used to measure voltage, current, and resistance in electrical circuits.

- Software Programming Tools: Used to update or reprogram the ECU’s software.

2.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Enhances ECU Assessment

CAR-DIAGNOSTIC-TOOL.EDU.VN provides resources and tools that enhance the assessment of ECU health:

- Comprehensive Diagnostic Guides: Detailed guides for interpreting DTCs, sensor data, and live data streams.

- Advanced Diagnostic Tools: Access to professional-grade scan tools and equipment.

- Technical Support: Expert assistance from certified technicians.

- Training Programs: Courses designed to enhance your diagnostic skills.

- Remote Support: Real-time assistance for troubleshooting and ECU calibrations.

By leveraging the resources available at CAR-DIAGNOSTIC-TOOL.EDU.VN, technicians and car enthusiasts can gain a deeper understanding of their vehicle’s ECU health, leading to more effective and efficient repairs. The calculation of a “Marshall ECU score” is not a simple equation, but a comprehensive evaluation of various factors that contribute to the overall health and performance of the ECU.

3. What Factors Influence The Marshall ECU Score?

The “Marshall ECU score,” while not a formally defined metric, is influenced by a range of factors that impact the performance and health of the engine control unit. These factors can be broadly categorized into sensor-related issues, electrical problems, software and calibration errors, and environmental conditions. Understanding these influences is crucial for accurate diagnostics and effective repairs.

3.1. Sensor-Related Issues

Sensors are the ECU’s primary source of information about the engine’s operating conditions. Faulty or inaccurate sensor readings can significantly affect the ECU’s ability to manage the engine effectively.

- Faulty Sensors: Sensors can fail due to wear and tear, contamination, or electrical damage.

- Inaccurate Readings: Sensors may provide readings that are out of range or inconsistent with actual conditions.

- Wiring Problems: Issues with sensor wiring, such as shorts, opens, or corrosion, can disrupt sensor signals.

Examples:

- Oxygen Sensors (O2 Sensors): A failing O2 sensor can provide incorrect readings about the oxygen content in the exhaust gas, leading to improper air-fuel mixture adjustments. According to a study by the EPA, faulty O2 sensors can decrease fuel efficiency by up to 40%.

- Mass Air Flow (MAF) Sensor: A contaminated or faulty MAF sensor can provide inaccurate readings about the amount of air entering the engine, causing the engine to run poorly or stall.

- Throttle Position Sensor (TPS): A malfunctioning TPS can cause erratic throttle response or idle issues.

Automotive sensors and their functions

Automotive sensors and their functions

3.2. Electrical Problems

The ECU relies on a stable and clean electrical supply to function correctly. Electrical issues can disrupt the ECU’s operation and lead to various performance problems.

- Power Supply Issues: Voltage drops, surges, or unstable power can affect the ECU’s internal circuitry.

- Grounding Problems: Poor grounding can cause electrical noise and interference, leading to inaccurate sensor readings and communication errors.

- Wiring Harness Issues: Damaged or corroded wiring harnesses can disrupt the flow of electrical signals to and from the ECU.

Examples:

- Voltage Drops: Low voltage can cause the ECU to operate erratically or shut down completely.

- Grounding Problems: Poor grounding can lead to inaccurate sensor readings and communication errors.

- Wiring Harness Issues: Damaged wiring can cause intermittent or complete loss of sensor signals.

3.3. Software and Calibration Errors

The ECU’s software and calibration data are crucial for its proper operation. Errors in the software or calibration can lead to various performance issues and diagnostic errors.

- Outdated Software: Outdated software may not be compatible with newer sensors or systems.

- Corrupted Software: Software can become corrupted due to electrical surges, programming errors, or other factors.

- Incorrect Calibration: Incorrect calibration data can cause the engine to run poorly or fail to meet emissions standards.

Examples:

- Outdated Software: The ECU may not be able to properly interpret data from newer sensors or systems.

- Corrupted Software: The ECU may exhibit erratic behavior or fail to start the engine.

- Incorrect Calibration: The engine may run too lean or too rich, leading to performance issues and emissions failures.

3.4. Environmental Conditions

Extreme environmental conditions can also impact the ECU’s performance and longevity.

- Temperature: Extreme heat or cold can affect the ECU’s internal components.

- Humidity: High humidity can cause corrosion and electrical shorts.

- Vibration: Excessive vibration can damage the ECU’s internal circuitry.

Examples:

- Temperature: High temperatures can cause the ECU’s internal components to overheat and fail.

- Humidity: High humidity can cause corrosion on electrical connectors and wiring.

- Vibration: Excessive vibration can damage the ECU’s internal circuitry.

3.5. How CAR-DIAGNOSTIC-TOOL.EDU.VN Helps Address These Factors

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support for diagnosing and addressing the factors that influence the “Marshall ECU score”:

- Detailed Diagnostic Guides: Step-by-step guides for diagnosing sensor-related issues, electrical problems, software errors, and environmental factors.

- Advanced Diagnostic Tools: Access to professional-grade scan tools, multimeters, and oscilloscopes.

- Technical Support: Expert assistance from certified technicians to help troubleshoot complex problems.

- Training Programs: Courses designed to enhance your diagnostic skills and knowledge of ECU systems.

- Remote Support: Real-time assistance to troubleshoot issues and perform ECU calibrations.

3.6. Preventative Measures

Taking preventative measures can help minimize the impact of these factors on the ECU’s health:

- Regular Maintenance: Performing regular maintenance, such as checking sensor connections and wiring harnesses, can help prevent sensor-related and electrical issues.

- Software Updates: Keeping the ECU’s software up-to-date can help ensure compatibility and proper operation.

- Protecting the ECU: Protecting the ECU from extreme temperatures, humidity, and vibration can help extend its lifespan.

By understanding the factors that influence the “Marshall ECU score” and taking preventative measures, technicians and car enthusiasts can ensure the ECU’s optimal performance and longevity.

4. How Can A Low Marshall ECU Score Affect Vehicle Performance?

A low “Marshall ECU score,” indicative of a compromised engine control unit, can trigger a cascade of performance issues in your vehicle. The ECU is the central computer managing numerous vital functions, and a poor score suggests that its ability to do so is impaired.

4.1. Reduced Fuel Efficiency

A compromised ECU struggles to maintain the optimal air-fuel mixture, leading to inefficient combustion. According to a study by the U.S. Department of Energy, an improperly tuned engine can reduce fuel efficiency by as much as 30%.

- Rich or Lean Conditions: The ECU may command the engine to run with too much fuel (rich) or too little fuel (lean), both of which reduce fuel economy.

- Inefficient Combustion: Incorrect timing and fuel delivery lead to incomplete combustion, wasting fuel.

4.2. Poor Engine Performance

With a low ECU score, the engine may exhibit symptoms such as:

- Misfires: The engine may misfire due to incorrect ignition timing or fuel delivery. Misfires can cause rough idling, poor acceleration, and increased emissions.

- Stalling: The engine may stall, especially at idle or during low-speed maneuvers, due to the ECU’s inability to maintain a stable idle.

- Hesitation: The engine may hesitate or stumble during acceleration due to incorrect fuel delivery or ignition timing.

4.3. Increased Emissions

An inefficiently operating ECU can cause the vehicle to produce excessive emissions, potentially leading to failed emissions tests and environmental damage.

- High Levels of Pollutants: The engine may produce high levels of hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) due to incomplete combustion.

- Catalytic Converter Damage: Excessive emissions can damage the catalytic converter, further increasing emissions and leading to costly repairs.

4.4. Transmission Issues

In modern vehicles, the ECU often communicates with the transmission control module (TCM) to coordinate engine and transmission operation. A low ECU score can disrupt this communication, leading to transmission issues such as:

- Harsh Shifting: The transmission may shift harshly or erratically due to incorrect engine torque signals from the ECU.

- Delayed Shifting: The transmission may delay shifting or fail to shift altogether due to communication problems with the ECU.

- Incorrect Gear Selection: The transmission may select the wrong gear for the driving conditions, leading to poor performance and reduced fuel economy.

4.5. Diagnostic Trouble Codes (DTCs)

A low ECU score is often accompanied by a plethora of DTCs, indicating various issues with the engine and related systems. These codes can make it difficult to diagnose the root cause of the problems, as they may be symptoms of a larger underlying issue with the ECU itself.

4.6. Safety Concerns

In some cases, a low ECU score can even lead to safety concerns. For example, if the ECU is unable to properly control the anti-lock braking system (ABS) or the electronic stability control (ESC), it can compromise the vehicle’s ability to brake or maintain stability in emergency situations.

4.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support for diagnosing and addressing the performance issues associated with a low “Marshall ECU score”:

- Detailed Diagnostic Guides: Step-by-step guides for diagnosing engine performance issues, transmission problems, and safety concerns.

- Advanced Diagnostic Tools: Access to professional-grade scan tools, multimeters, and oscilloscopes.

- Technical Support: Expert assistance from certified technicians to help troubleshoot complex problems.

- Training Programs: Courses designed to enhance your diagnostic skills and knowledge of ECU systems.

- Remote Support: Real-time assistance to troubleshoot issues and perform ECU calibrations.

4.8. Case Study: Impact on Vehicle Resale Value

A vehicle with a history of ECU issues or a consistently low “Marshall ECU score” can experience a significant decrease in resale value. Potential buyers may be wary of purchasing a vehicle with known ECU problems, as they can lead to costly repairs and ongoing performance issues.

By addressing the underlying causes of a low ECU score and restoring the ECU to optimal health, technicians and car enthusiasts can improve vehicle performance, reduce emissions, and enhance safety.

5. How To Improve Your Vehicle’s Marshall ECU Score

Improving your vehicle’s “Marshall ECU score” involves a strategic approach to diagnostics and maintenance, focusing on the key factors that influence ECU performance. Here’s a detailed guide on how to enhance your vehicle’s ECU health.

5.1. Comprehensive Diagnostic Scan

Start with a comprehensive diagnostic scan using a professional-grade scan tool. This will help identify any Diagnostic Trouble Codes (DTCs) stored in the ECU’s memory.

- Read and Record DTCs: Note all DTCs present, as they provide valuable clues about potential issues.

- Clear DTCs: After recording the DTCs, clear them from the ECU’s memory. This allows you to see which codes reappear during subsequent driving cycles.

- Verify DTC Definitions: Use a reliable source to verify the definitions of each DTC. This ensures you understand the specific issue indicated by the code.

5.2. Sensor Testing and Replacement

Sensors play a crucial role in providing accurate data to the ECU. Testing and replacing faulty sensors is essential for improving ECU performance.

- Inspect Sensor Wiring: Check the wiring and connectors for any signs of damage, corrosion, or loose connections.

- Test Sensor Output: Use a multimeter or oscilloscope to test the output of each sensor. Compare the readings to the manufacturer’s specifications.

- Replace Faulty Sensors: Replace any sensors that are not functioning within the specified range. Common sensors to check include:

- Oxygen Sensors (O2 Sensors)

- Mass Air Flow (MAF) Sensor

- Throttle Position Sensor (TPS)

- Crankshaft Position Sensor (CKP)

- Camshaft Position Sensor (CMP)

5.3. Electrical System Inspection

The ECU relies on a stable and clean electrical supply to function correctly. Inspecting the electrical system for any issues is crucial for improving ECU performance.

- Check Battery Voltage: Ensure the battery is in good condition and providing the correct voltage. A weak battery can cause erratic ECU behavior.

- Inspect Ground Connections: Check all ground connections for corrosion or looseness. Poor grounding can cause electrical noise and interference.

- Test Charging System: Verify that the charging system is functioning correctly and providing the correct voltage to the battery.

- Inspect Wiring Harness: Check the wiring harness for any signs of damage, such as frayed wires or cracked insulation.

5.4. Software Updates and Calibration

Ensuring that the ECU’s software is up-to-date and correctly calibrated is essential for optimal performance.

- Check for Software Updates: Check with the vehicle manufacturer or a qualified technician to see if there are any software updates available for the ECU.

- Update ECU Software: If updates are available, follow the manufacturer’s instructions to update the ECU software.

- Verify Calibration Data: Ensure that the calibration data is correct for the vehicle’s make, model, and engine configuration.

5.5. Mechanical Component Inspection

Mechanical issues can also affect ECU performance. Inspecting key mechanical components can help identify and address potential problems.

- Check for Vacuum Leaks: Vacuum leaks can cause the engine to run lean, leading to poor performance and increased emissions. Use a smoke machine or carburetor cleaner to check for vacuum leaks.

- Inspect Fuel System: Check the fuel injectors, fuel pump, and fuel filter for any signs of contamination or malfunction.

- Test Compression: Perform a compression test to check the health of the engine’s cylinders. Low compression can indicate worn piston rings or valves.

5.6. Regular Maintenance

Performing regular maintenance can help prevent issues that can negatively impact the ECU’s performance.

- Change Engine Oil: Change the engine oil and filter at the recommended intervals.

- Replace Air Filter: Replace the air filter regularly to ensure that the engine is receiving clean air.

- Service Fuel System: Have the fuel system serviced at the recommended intervals to prevent fuel injector clogging and other issues.

5.7. How CAR-DIAGNOSTIC-TOOL.EDU.VN Can Help

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support for improving your vehicle’s “Marshall ECU score”:

- Detailed Diagnostic Guides: Step-by-step guides for diagnosing and addressing sensor issues, electrical problems, software errors, and mechanical issues.

- Advanced Diagnostic Tools: Access to professional-grade scan tools, multimeters, and oscilloscopes.

- Technical Support: Expert assistance from certified technicians to help troubleshoot complex problems.

- Training Programs: Courses designed to enhance your diagnostic skills and knowledge of ECU systems.

- Remote Support: Real-time assistance to troubleshoot issues and perform ECU calibrations.

5.8. Case Study: Real-World Improvement

Consider a scenario where a vehicle has a low “Marshall ECU score” due to a faulty oxygen sensor and a vacuum leak. By replacing the oxygen sensor, repairing the vacuum leak, and updating the ECU software, the vehicle’s performance can be significantly improved, resulting in a higher “Marshall ECU score.”

By following these steps and leveraging the resources available at CAR-DIAGNOSTIC-TOOL.EDU.VN, you can improve your vehicle’s “Marshall ECU score” and enjoy enhanced performance, fuel efficiency, and reliability.

6. What Tools Are Needed To Diagnose The Marshall ECU Score?

Diagnosing and improving a vehicle’s “Marshall ECU score” requires a combination of specialized tools and equipment. These tools help technicians accurately assess the ECU’s health, identify potential issues, and perform necessary repairs or adjustments. Here’s a comprehensive list of essential tools for diagnosing the “Marshall ECU score.”

6.1. Diagnostic Scan Tool

A diagnostic scan tool, also known as an OBD-II scanner, is the most essential tool for diagnosing the “Marshall ECU score.” This tool allows you to read Diagnostic Trouble Codes (DTCs), monitor live data streams, and perform various diagnostic tests.

- Functionality:

- Reading DTCs: Retrieves stored DTCs from the ECU’s memory.

- Clearing DTCs: Erases DTCs from the ECU’s memory after repairs.

- Live Data Monitoring: Displays real-time data from various sensors and systems.

- Actuator Testing: Activates specific components to verify their functionality.

- Freeze Frame Data: Captures sensor data at the moment a DTC was triggered.

- Types of Scan Tools:

- Basic Scan Tools: Suitable for reading and clearing DTCs.

- Professional-Grade Scan Tools: Offer advanced features such as live data monitoring, actuator testing, and bi-directional control.

- Recommendation: Invest in a professional-grade scan tool for comprehensive diagnostic capabilities.

6.2. Multimeter

A multimeter is a versatile tool used to measure voltage, current, and resistance in electrical circuits. It’s essential for testing sensors, wiring, and other electrical components.

- Functionality:

- Voltage Measurement: Measures the voltage in electrical circuits.

- Current Measurement: Measures the current flowing through electrical circuits.

- Resistance Measurement: Measures the resistance of electrical components.

- Continuity Testing: Checks for breaks in electrical circuits.

- Features to Look For:

- Digital Display: Provides accurate and easy-to-read measurements.

- Auto-Ranging: Automatically selects the appropriate measurement range.

- Continuity Buzzer: Emits an audible tone when a circuit is complete.

- Recommendation: Choose a digital multimeter with auto-ranging and a continuity buzzer for efficient troubleshooting.

6.3. Oscilloscope

An oscilloscope is used to analyze electrical signals over time. It’s particularly useful for diagnosing intermittent sensor problems and identifying signal abnormalities.

- Functionality:

- Signal Analysis: Displays electrical signals as waveforms, allowing you to analyze their shape, amplitude, and frequency.

- Intermittent Problem Detection: Captures intermittent signal drops or spikes that may not be visible with a multimeter.

- Sensor Testing: Tests the output of various sensors to ensure they are functioning correctly.

- Features to Look For:

- High Sampling Rate: Provides accurate and detailed waveforms.

- Multiple Channels: Allows you to monitor multiple signals simultaneously.

- Built-In Diagnostics: Offers pre-programmed tests for common automotive components.

- Recommendation: Consider a portable oscilloscope with a high sampling rate and multiple channels for versatile diagnostics.

6.4. Fuel Pressure Tester

A fuel pressure tester is used to measure the pressure in the fuel system. It’s essential for diagnosing fuel-related issues that can affect ECU performance.

- Functionality:

- Fuel Pressure Measurement: Measures the pressure in the fuel system to ensure it’s within the manufacturer’s specifications.

- Fuel Pump Testing: Tests the performance of the fuel pump.

- Fuel Regulator Testing: Checks the functionality of the fuel pressure regulator.

- Features to Look For:

- Accurate Gauge: Provides precise fuel pressure readings.

- Adaptable Fittings: Includes fittings to connect to various fuel systems.

- Pressure Relief Valve: Allows you to safely relieve pressure from the fuel system.

- Recommendation: Choose a fuel pressure tester with an accurate gauge and adaptable fittings for versatile use.

6.5. Vacuum Tester

A vacuum tester is used to measure the vacuum in the engine’s intake manifold. It’s essential for diagnosing vacuum leaks that can affect ECU performance.

- Functionality:

- Vacuum Measurement: Measures the vacuum in the intake manifold.

- Vacuum Leak Detection: Helps identify vacuum leaks in hoses, gaskets, and seals.

- Engine Performance Analysis: Provides insights into the engine’s overall health and performance.

- Features to Look For:

- Accurate Gauge: Provides precise vacuum readings.

- Adaptable Fittings: Includes fittings to connect to various vacuum lines.

- Durable Construction: Built to withstand the harsh environment of an engine bay.

- Recommendation: Choose a vacuum tester with an accurate gauge and durable construction for reliable use.

6.6. Compression Tester

A compression tester is used to measure the compression in each of the engine’s cylinders. It’s essential for diagnosing engine mechanical issues that can affect ECU performance.

- Functionality:

- Compression Measurement: Measures the compression in each cylinder.

- Cylinder Health Assessment: Provides insights into the health of the engine’s cylinders.

- Valve and Ring Testing: Helps identify issues with valves and piston rings.

- Features to Look For:

- Accurate Gauge: Provides precise compression readings.

- Adaptable Fittings: Includes fittings to connect to various spark plug ports.

- Durable Construction: Built to withstand the high-pressure environment of an engine.

- Recommendation: Choose a compression tester with an accurate gauge and durable construction for reliable use.

6.7. Software Programming Tools

Software programming tools are used to update or reprogram the ECU’s software. These tools are essential for addressing software-related issues that can affect ECU performance.

- Functionality:

- ECU Programming: Updates or reprograms the ECU’s software.

- Calibration Adjustment: Adjusts the ECU’s calibration data.

- Module Configuration: Configures the ECU to match the vehicle’s specifications.

- Types of Programming Tools:

- OEM Programming Tools: Provided by the vehicle manufacturer.

- Aftermarket Programming Tools: Offered by third-party vendors.

- Recommendation: Use OEM programming tools or reputable aftermarket tools for reliable ECU programming.

6.8. How CAR-DIAGNOSTIC-TOOL.EDU.VN Supports Tool Usage

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support for using these diagnostic tools:

- Detailed Guides: Step-by-step guides on how to use each tool effectively.

- Troubleshooting Tips: Expert tips on diagnosing common issues.

- Technical Support: Access to certified technicians for assistance.

- Training Programs: Courses to enhance your diagnostic skills.

By using these tools and leveraging the resources available at CAR-DIAGNOSTIC-TOOL.EDU.VN, technicians and car enthusiasts can effectively diagnose and improve their vehicle’s “Marshall ECU score.”

7. Common Mistakes To Avoid When Interpreting The Marshall ECU Score

Interpreting the “Marshall ECU score” and diagnosing related issues can be complex, and it’s easy to make mistakes that lead to incorrect diagnoses and ineffective repairs. Here are some common mistakes to avoid when interpreting the “Marshall ECU score.”

7.1. Ignoring Basic Mechanical Issues

One of the most common mistakes is focusing solely on the ECU and electronic components while overlooking basic mechanical issues.

- Problem: Assuming that all issues are electronic when mechanical problems may be the root cause.

- Example: A misfire code (P0300) could be caused by a faulty spark plug, a worn ignition coil, or a more serious mechanical issue such as low compression.

- Solution: Always start with a thorough inspection of basic mechanical components before diving into electronic diagnostics. Check for vacuum leaks, fuel pressure, compression, and other mechanical issues.

7.2. Neglecting Wiring And Connections

Wiring and connections are often overlooked, but they can be a significant source of problems that affect the ECU’s performance.

- Problem: Assuming that sensors and components are faulty when the issue is simply a wiring or connection problem.

- Example: An oxygen sensor code (P0131) could be caused by a faulty oxygen sensor, but it could also be caused by a broken wire or a corroded connector.

- Solution: Carefully inspect wiring harnesses and connectors for damage, corrosion, or loose connections. Use a multimeter to check for continuity and voltage at the sensor and ECU terminals.

7.3. Failing To Verify Sensor Data

Relying solely on DTCs without verifying sensor data can lead to incorrect diagnoses.

- Problem: Assuming that a sensor is faulty based only on a DTC, without checking the sensor’s actual output.

- Example: A mass air flow (MAF) sensor code (P0101) could be triggered by a faulty MAF sensor, but it could also be caused by a vacuum leak or a dirty air filter.

- Solution: Use a scan tool to monitor the sensor’s live data and compare it to the manufacturer’s specifications. Verify that the sensor’s output changes appropriately as the engine’s operating conditions change.

7.4. Ignoring Freeze Frame Data

Freeze frame data captures sensor values at the moment a DTC was triggered. Ignoring this data can make it difficult to diagnose intermittent problems.

- Problem: Clearing DTCs without analyzing the freeze frame data, which can provide valuable clues about the conditions that caused the code to be set.

- Example: An engine misfire code (P0300) may have been triggered at high RPM and under heavy load. This information can help you narrow down the possible causes of the misfire.

- Solution: Always analyze the freeze frame data before clearing DTCs. Look for any unusual sensor values or operating conditions that may have contributed to the problem.

7.5. Not Considering Software Updates

Outdated ECU software can cause various problems, including incorrect DTCs, poor performance, and compatibility issues with newer sensors and components.

- Problem: Assuming that the ECU’s software is up-to-date, when it may be outdated and causing problems.

- Example: An ECU with outdated software may not be