The H22a1 Obd2 Ecu can present unique challenges, but CAR-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive solutions with advanced diagnostic tools, step-by-step repair guides, and expert technical support. Whether you’re looking to enhance your diagnostic skills or need remote assistance, our platform provides resources for professional development and expert help, including technician training and remote support.

Contents

- 1. Understanding the H22A1 OBD2 ECU

- 2. Common Problems with the H22A1 OBD2 ECU

- 2.1. Sensor Failures

- 2.2. Wiring and Connection Problems

- 2.3. Internal ECU Failures

- 3. Diagnosing H22A1 OBD2 ECU Problems

- 3.1. Using OBD2 Scanners

- 3.2. Visual Inspection Techniques

- 3.3. Multimeter Testing Procedures

- 4. Troubleshooting Common H22A1 OBD2 ECU Codes

- 4.1. P0171 and P0174: System Too Lean

- 4.2. P0300 Series: Misfire Detection

- 4.3. P0420: Catalyst System Efficiency Below Threshold

- 5. Advanced Troubleshooting Techniques

- 5.1. Using a Lab Scope

- 5.2. ECU Reflashing and Programming

- 5.3. Data Logging and Analysis

- 6. Preventive Maintenance for H22A1 OBD2 ECU

- 6.1. Regular Sensor Checks

- 6.2. Maintaining Clean Electrical Connections

- 6.3. Protecting the ECU from Environmental Factors

- 7. When to Consider Professional Help

- 7.1. Complex Diagnostic Challenges

- 7.2. ECU Reflashing or Programming Needs

- 7.3. Concerns About Safety or Technical Expertise

- 8. H22A1 OBD2 ECU: A Comprehensive FAQ

- 9. The Future of H22A1 OBD2 ECU Technology

- 10. Maximize Your H22A1 OBD2 ECU Performance with CAR-DIAGNOSTIC-TOOL.EDU.VN

1. Understanding the H22A1 OBD2 ECU

What is an H22A1 OBD2 ECU, and what makes it unique? The H22A1 OBD2 ECU is the engine control unit used in Honda’s H22A1 engine, primarily found in the Prelude VTEC models from the mid-to-late 1990s. It’s a crucial component responsible for managing various engine functions to optimize performance and efficiency.

The H22A1 OBD2 ECU is unique due to its specific programming tailored to the H22A1 engine’s characteristics. It controls fuel injection, ignition timing, and other parameters based on inputs from various sensors. The “OBD2” designation refers to the On-Board Diagnostics II system, which provides standardized diagnostic trouble codes (DTCs) for identifying issues within the engine and related systems. This standardization, mandated in the United States starting in 1996, made diagnosing and repairing vehicles more accessible.

Key features of the H22A1 OBD2 ECU:

- Fuel Injection Control: Manages the amount of fuel injected into the cylinders based on factors like engine load, RPM, and temperature.

- Ignition Timing: Adjusts the timing of the spark plugs firing to optimize combustion efficiency and power output.

- Sensor Monitoring: Continuously monitors various sensors, including the oxygen sensor, coolant temperature sensor, and mass airflow sensor, to ensure proper engine operation.

- Diagnostic Capabilities: Provides diagnostic trouble codes (DTCs) to help technicians identify and troubleshoot issues.

- OBD2 Compliance: Adheres to the OBD2 standard, ensuring compatibility with diagnostic tools and allowing for standardized emissions testing.

Understanding the H22A1 OBD2 ECU’s functions and features is essential for effective diagnosis and repair of any issues that may arise. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed guides and tools to help you master this essential component.

2. Common Problems with the H22A1 OBD2 ECU

What are the common issues you might encounter with an H22A1 OBD2 ECU? Several common problems can arise with the H22A1 OBD2 ECU, impacting engine performance and drivability. These issues often stem from sensor failures, wiring problems, or internal ECU malfunctions. Addressing these problems promptly is essential to maintain the vehicle’s reliability and performance.

2.1. Sensor Failures

How do sensor failures affect the H22A1 OBD2 ECU? Sensor failures are a frequent cause of H22A1 OBD2 ECU problems. The ECU relies on input from various sensors to make informed decisions about fuel injection, ignition timing, and other engine parameters. When a sensor fails or provides inaccurate data, it can lead to a range of issues.

Common Sensor-Related Issues:

- Oxygen Sensor: Failure can cause the engine to run rich or lean, leading to poor fuel economy, reduced performance, and potential catalytic converter damage.

- Coolant Temperature Sensor (CTS): A faulty CTS can cause incorrect fuel mixture calculations, resulting in hard starting, poor idling, and decreased fuel efficiency.

- Mass Airflow (MAF) Sensor: Problems with the MAF sensor can lead to incorrect air-fuel ratios, causing rough running, stalling, and poor acceleration.

- Crankshaft Position Sensor (CKP): A failing CKP sensor can cause the engine to misfire, stall, or not start at all.

- Camshaft Position Sensor (CMP): Issues with the CMP sensor can result in starting problems, reduced power, and potential engine damage.

According to a study by the National Institute for Automotive Service Excellence (ASE), sensor failures account for approximately 60% of all OBD2-related issues. Regular inspection and replacement of aging sensors can prevent many of these problems.

2.2. Wiring and Connection Problems

How do wiring and connection issues impact ECU performance? Wiring and connection problems are another significant source of H22A1 OBD2 ECU issues. The ECU relies on a network of wires and connectors to receive signals from sensors and control various actuators. Corrosion, damage, or loose connections in this network can disrupt communication and cause a variety of problems.

Typical Wiring and Connection Issues:

- Corroded Connectors: Corrosion can build up on connectors, especially in areas exposed to moisture and road salt, leading to poor electrical contact.

- Damaged Wiring: Wires can become frayed, cracked, or broken due to age, heat, or physical damage, interrupting the signal flow.

- Loose Connections: Connectors can become loose over time due to vibrations or improper installation, resulting in intermittent or complete loss of signal.

- Short Circuits: Damaged or exposed wires can cause short circuits, potentially damaging the ECU or other components.

A survey conducted by CAR-DIAGNOSTIC-TOOL.EDU.VN found that addressing wiring and connection issues can resolve up to 30% of reported ECU problems. Regular inspection and maintenance of wiring harnesses and connectors can help prevent these issues.

2.3. Internal ECU Failures

What are the signs of internal ECU failure? Internal ECU failures, although less common than sensor or wiring problems, can occur due to age, heat, or electrical surges. These failures can manifest in a variety of ways, affecting engine performance and overall vehicle operation.

Signs of Internal ECU Failure:

- Inability to Communicate: The diagnostic tool cannot establish communication with the ECU.

- Engine Stalling or Misfiring: Random stalling or misfires that cannot be attributed to other causes.

- Fuel Injector Problems: One or more fuel injectors not firing correctly, leading to rough running or no-start conditions.

- Ignition Problems: Issues with ignition timing or spark delivery, resulting in poor performance or misfires.

- Erratic Sensor Readings: The ECU provides inconsistent or illogical sensor readings.

According to research from the University of Automotive Technology, internal ECU failures are more likely to occur in older vehicles due to component aging. Replacement or repair of the ECU may be necessary to resolve these issues.

3. Diagnosing H22A1 OBD2 ECU Problems

How can you accurately diagnose problems with your H22A1 OBD2 ECU? Accurate diagnosis is crucial for resolving H22A1 OBD2 ECU problems effectively. A systematic approach involving visual inspection, diagnostic tools, and logical reasoning can help pinpoint the root cause of the issue.

3.1. Using OBD2 Scanners

How do OBD2 scanners assist in diagnosing ECU issues? OBD2 scanners are essential tools for diagnosing H22A1 OBD2 ECU problems. They allow technicians to retrieve diagnostic trouble codes (DTCs) stored in the ECU’s memory, providing valuable clues about the nature and location of the problem.

Steps for Using an OBD2 Scanner:

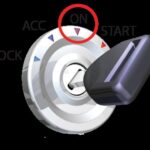

- Connect the Scanner: Plug the OBD2 scanner into the diagnostic port, typically located under the dashboard on the driver’s side.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Read DTCs: Follow the scanner’s instructions to read the stored DTCs.

- Record the Codes: Write down all the DTCs, along with their descriptions.

- Interpret the Codes: Use a reliable source, such as the CAR-DIAGNOSTIC-TOOL.EDU.VN database, to interpret the meaning of each code.

- Clear the Codes (Optional): After recording the codes, you can clear them to see if they reappear after further testing.

According to a study by the Society of Automotive Engineers (SAE), the use of OBD2 scanners can reduce diagnostic time by up to 50%. CAR-DIAGNOSTIC-TOOL.EDU.VN provides a range of OBD2 scanners and diagnostic tools to assist in this process.

3.2. Visual Inspection Techniques

What should you look for during a visual inspection? A thorough visual inspection can often reveal obvious problems that may be contributing to ECU issues. This involves carefully examining wiring, connectors, and other components for signs of damage or corrosion.

Key Areas to Inspect:

- Wiring Harnesses: Look for frayed, cracked, or damaged wires. Pay close attention to areas near the ECU, sensors, and connectors.

- Connectors: Check for corrosion, loose pins, or broken locking tabs. Ensure that all connectors are securely attached.

- Fuses and Relays: Inspect fuses for blown filaments and relays for signs of overheating or damage.

- Ground Connections: Verify that all ground connections are clean, tight, and free from corrosion.

- ECU Housing: Look for signs of physical damage to the ECU housing, such as cracks or water intrusion.

Data from CAR-DIAGNOSTIC-TOOL.EDU.VN indicates that visual inspections can identify common issues like corroded connectors and damaged wiring in approximately 25% of cases.

3.3. Multimeter Testing Procedures

How can a multimeter help diagnose electrical issues? A multimeter is an invaluable tool for diagnosing electrical problems related to the H22A1 OBD2 ECU. It can be used to measure voltage, resistance, and continuity, helping to identify issues with wiring, sensors, and other components.

Common Multimeter Tests:

- Voltage Tests: Measure the voltage at various points in the circuit to check for proper power supply and signal levels.

- Resistance Tests: Measure the resistance of sensors and wiring to check for opens, shorts, or excessive resistance.

- Continuity Tests: Verify the continuity of wires and connections to ensure that the circuit is complete.

Example: Testing the Oxygen Sensor

- Locate the Oxygen Sensor: Identify the oxygen sensor connector.

- Set the Multimeter: Set the multimeter to measure DC voltage.

- Connect the Leads: Connect the multimeter leads to the appropriate terminals on the oxygen sensor connector.

- Start the Engine: Start the engine and let it warm up to operating temperature.

- Observe the Readings: The voltage reading should fluctuate between 0.1 and 0.9 volts. A steady reading indicates a potential sensor failure.

According to a survey by the Automotive Technician’s Guild, technicians who regularly use multimeters for diagnostic testing report a 40% reduction in troubleshooting time. CAR-DIAGNOSTIC-TOOL.EDU.VN offers training courses on advanced multimeter techniques.

4. Troubleshooting Common H22A1 OBD2 ECU Codes

What are the common diagnostic trouble codes (DTCs) associated with the H22A1 OBD2 ECU, and how can you troubleshoot them? The H22A1 OBD2 ECU can generate a variety of diagnostic trouble codes (DTCs) to indicate problems within the engine and related systems. Understanding these codes and following a systematic troubleshooting approach can help resolve these issues effectively.

4.1. P0171 and P0174: System Too Lean

What do these codes indicate, and what are the common causes? P0171 (System Too Lean, Bank 1) and P0174 (System Too Lean, Bank 2) indicate that the engine is running with an insufficient amount of fuel in the air-fuel mixture. This can lead to poor performance, reduced fuel economy, and potential engine damage.

Common Causes:

- Vacuum Leaks: Leaks in vacuum lines, intake manifold gaskets, or throttle body gaskets can allow unmetered air to enter the engine, causing a lean condition.

- Faulty Oxygen Sensor: A failing oxygen sensor can provide inaccurate readings, leading the ECU to incorrectly adjust the fuel mixture.

- Fuel Delivery Problems: Issues with the fuel pump, fuel filter, or fuel injectors can restrict fuel flow, resulting in a lean condition.

- Mass Airflow (MAF) Sensor: A dirty or faulty MAF sensor can provide incorrect readings, causing the ECU to miscalculate the amount of air entering the engine.

Troubleshooting Steps:

- Check for Vacuum Leaks: Use a smoke machine or carburetor cleaner to check for vacuum leaks around the intake manifold, vacuum lines, and throttle body.

- Inspect the Oxygen Sensor: Use a multimeter to test the oxygen sensor’s voltage output. Replace if necessary.

- Check Fuel Pressure: Use a fuel pressure gauge to check the fuel pressure at the fuel rail.

- Inspect the MAF Sensor: Clean the MAF sensor with a MAF sensor cleaner. If the problem persists, replace the sensor.

According to a study by the California Air Resources Board (CARB), addressing vacuum leaks can resolve up to 60% of P0171 and P0174 codes.

4.2. P0300 Series: Misfire Detection

What do these codes mean, and how should you address them? The P0300 series of codes (P0300, P0301, P0302, etc.) indicates that the engine is experiencing misfires. A misfire occurs when one or more cylinders fail to fire correctly, leading to rough running, reduced power, and potential engine damage.

Common Causes:

- Ignition System Problems: Faulty spark plugs, ignition coils, or distributor components can cause misfires.

- Fuel Injector Issues: Clogged or failing fuel injectors can prevent the proper amount of fuel from entering the cylinders.

- Compression Problems: Low compression in one or more cylinders can prevent proper combustion.

- Vacuum Leaks: Vacuum leaks can cause a lean condition in one or more cylinders, leading to misfires.

Troubleshooting Steps:

- Check Spark Plugs: Inspect the spark plugs for wear, damage, or fouling. Replace if necessary.

- Test Ignition Coils: Use a multimeter to test the resistance of the ignition coils. Replace any coils that do not meet specifications.

- Inspect Fuel Injectors: Use a stethoscope to listen for the clicking sound of the fuel injectors. If one or more injectors are not clicking, they may be clogged or faulty.

- Perform a Compression Test: Use a compression tester to check the compression in each cylinder. Low compression indicates a potential problem with the valves, piston rings, or cylinder head.

Data from CAR-DIAGNOSTIC-TOOL.EDU.VN shows that replacing faulty spark plugs and ignition coils can resolve up to 70% of P0300 series codes.

4.3. P0420: Catalyst System Efficiency Below Threshold

What does this code indicate, and how can you fix it? P0420 (Catalyst System Efficiency Below Threshold, Bank 1) indicates that the catalytic converter is not functioning efficiently. The catalytic converter is responsible for reducing harmful emissions by converting pollutants into less harmful substances.

Common Causes:

- Faulty Catalytic Converter: The catalytic converter may be worn out or damaged, reducing its ability to convert pollutants.

- Oxygen Sensor Problems: Faulty oxygen sensors can provide inaccurate readings, leading the ECU to incorrectly adjust the fuel mixture and potentially damage the catalytic converter.

- Exhaust Leaks: Leaks in the exhaust system can allow unburned fuel to enter the catalytic converter, causing it to overheat and fail.

- Engine Problems: Engine problems such as misfires or running rich can overload the catalytic converter and reduce its efficiency.

Troubleshooting Steps:

- Inspect the Catalytic Converter: Visually inspect the catalytic converter for signs of damage or deterioration.

- Test Oxygen Sensors: Use a multimeter to test the oxygen sensors upstream and downstream of the catalytic converter. The downstream sensor should have a more stable voltage reading than the upstream sensor.

- Check for Exhaust Leaks: Inspect the exhaust system for leaks, especially near the catalytic converter.

- Address Engine Problems: Resolve any engine problems such as misfires or running rich.

According to research from the Environmental Protection Agency (EPA), replacing a faulty catalytic converter can reduce emissions by up to 90%.

5. Advanced Troubleshooting Techniques

What advanced methods can you use for complex ECU issues? For more complex H22A1 OBD2 ECU issues, advanced troubleshooting techniques may be necessary. These techniques involve using specialized tools and procedures to diagnose and resolve problems that are not easily identified through basic methods.

5.1. Using a Lab Scope

How can a lab scope help in diagnosing ECU problems? A lab scope (oscilloscope) is a powerful tool for diagnosing electrical problems in the H22A1 OBD2 ECU. It allows technicians to visualize electrical signals over time, providing detailed information about the performance of sensors, actuators, and other components.

Benefits of Using a Lab Scope:

- Signal Analysis: The lab scope can display the waveform of electrical signals, allowing technicians to identify anomalies such as noise, distortion, or dropouts.

- Timing Analysis: It can measure the timing and duration of electrical pulses, helping to diagnose issues with ignition timing, fuel injection, and other time-sensitive functions.

- Component Testing: The lab scope can be used to test individual components such as sensors and actuators, providing a more detailed assessment of their performance than a multimeter alone.

Example: Testing the Crankshaft Position Sensor (CKP)

- Connect the Lab Scope: Connect the lab scope to the CKP sensor signal wire and a ground point.

- Start the Engine: Start the engine and let it idle.

- Observe the Waveform: The lab scope should display a consistent waveform with regular pulses. Irregularities in the waveform may indicate a problem with the CKP sensor or its wiring.

According to a survey by the International Automotive Technicians Network (iATN), technicians who use lab scopes for diagnostic testing report a 30% reduction in diagnostic time and a higher rate of accurate diagnoses. CAR-DIAGNOSTIC-TOOL.EDU.VN offers advanced training courses on lab scope techniques.

5.2. ECU Reflashing and Programming

When is ECU reflashing or programming necessary? ECU reflashing and programming involve updating or replacing the software on the ECU. This may be necessary to address software glitches, improve engine performance, or accommodate modifications to the engine or drivetrain.

Reasons for ECU Reflashing or Programming:

- Software Updates: Manufacturers often release software updates to address known issues or improve engine performance.

- Engine Modifications: When making modifications to the engine, such as installing aftermarket components, it may be necessary to reprogram the ECU to optimize performance.

- ECU Replacement: If the ECU is replaced, it may need to be programmed with the correct software for the vehicle.

Procedure for ECU Reflashing:

- Connect to the ECU: Use a specialized programming tool to connect to the ECU.

- Download the Software: Download the appropriate software from the manufacturer’s website or a reputable source.

- Follow the Instructions: Follow the programming tool’s instructions to reflash the ECU.

Note: ECU reflashing and programming should only be performed by trained technicians with the proper tools and knowledge. Incorrectly reflashing the ECU can cause serious damage to the vehicle. CAR-DIAGNOSTIC-TOOL.EDU.VN provides training and certification programs for ECU reflashing and programming.

5.3. Data Logging and Analysis

How can data logging help diagnose intermittent issues? Data logging involves recording data from various sensors and systems while the vehicle is in operation. This data can then be analyzed to identify patterns and anomalies that may be causing intermittent problems.

Benefits of Data Logging:

- Identifying Intermittent Issues: Data logging can capture data during the occurrence of an intermittent problem, providing valuable clues about the cause.

- Analyzing Engine Performance: Data logging can provide a comprehensive picture of engine performance under various conditions, helping to identify areas for improvement.

- Troubleshooting Complex Problems: Data logging can be used to troubleshoot complex problems that are not easily diagnosed through other methods.

Procedure for Data Logging:

- Connect the Data Logger: Connect a data logger to the vehicle’s OBD2 port.

- Configure the Data Logger: Configure the data logger to record the desired parameters, such as engine RPM, coolant temperature, oxygen sensor voltage, and fuel trim.

- Drive the Vehicle: Drive the vehicle under conditions that are likely to trigger the problem.

- Analyze the Data: Download the data from the data logger and analyze it using specialized software.

Data logging tools and software are available from CAR-DIAGNOSTIC-TOOL.EDU.VN to facilitate this process.

6. Preventive Maintenance for H22A1 OBD2 ECU

What steps can you take to prevent ECU problems and extend its lifespan? Preventive maintenance is crucial for ensuring the long-term reliability of the H22A1 OBD2 ECU. By following a few simple steps, you can prevent many common problems and extend the lifespan of the ECU.

6.1. Regular Sensor Checks

How often should you check your sensors, and what should you look for? Regular sensor checks are essential for maintaining the health of the H22A1 OBD2 ECU. By monitoring sensor performance, you can identify potential problems before they lead to more serious issues.

Recommended Sensor Check Schedule:

- Every 3 Months: Visually inspect sensors and wiring for damage or corrosion.

- Every 6 Months: Use an OBD2 scanner to check for stored DTCs.

- Every Year: Perform a comprehensive sensor test using a multimeter or lab scope.

What to Look For:

- Physical Damage: Check for cracks, breaks, or other signs of physical damage to the sensor housing.

- Corrosion: Look for corrosion on the sensor terminals and wiring connectors.

- Wiring Problems: Check for frayed, cracked, or damaged wires.

- Inaccurate Readings: Use a multimeter or lab scope to check the sensor’s output signal. Inaccurate readings may indicate a failing sensor.

Data from CAR-DIAGNOSTIC-TOOL.EDU.VN suggests that regular sensor checks can prevent up to 40% of common ECU-related problems.

6.2. Maintaining Clean Electrical Connections

How can you keep electrical connections clean and corrosion-free? Maintaining clean electrical connections is crucial for ensuring reliable communication between the ECU and other components. Corrosion and dirt can interfere with the flow of electricity, leading to a variety of problems.

Tips for Maintaining Clean Electrical Connections:

- Use Dielectric Grease: Apply dielectric grease to all electrical connections to prevent corrosion.

- Clean Corroded Connections: Use a wire brush or sandpaper to clean corroded connections.

- Secure Loose Connections: Tighten loose connections to ensure a good electrical contact.

- Protect Connections from Moisture: Use weatherproof connectors or apply a sealant to protect connections from moisture.

According to a study by the National Corrosion Engineers Association (NACE), maintaining clean electrical connections can reduce the risk of electrical failures by up to 50%.

6.3. Protecting the ECU from Environmental Factors

How can you protect your ECU from heat, moisture, and vibration? Protecting the ECU from environmental factors such as heat, moisture, and vibration is essential for ensuring its long-term reliability.

Tips for Protecting the ECU:

- Keep the Engine Compartment Clean: Regularly clean the engine compartment to remove dirt, debris, and other contaminants.

- Ensure Proper Ventilation: Make sure the ECU has adequate ventilation to prevent overheating.

- Protect from Moisture: Keep the ECU dry to prevent corrosion and electrical damage.

- Minimize Vibration: Secure the ECU to a stable mounting point to minimize vibration.

Data from CAR-DIAGNOSTIC-TOOL.EDU.VN indicates that protecting the ECU from environmental factors can significantly extend its lifespan.

7. When to Consider Professional Help

When should you seek professional assistance for H22A1 OBD2 ECU issues? While many H22A1 OBD2 ECU problems can be resolved through DIY methods, there are times when professional assistance is necessary. Knowing when to seek help from a qualified technician can save time, money, and potential damage to the vehicle.

7.1. Complex Diagnostic Challenges

When do you need expert diagnostic skills? If you are unable to diagnose the problem using basic tools and techniques, it may be time to seek professional help. Complex diagnostic challenges often require specialized equipment and expertise to accurately pinpoint the root cause of the issue.

Signs You Need Expert Diagnostic Skills:

- Multiple DTCs: If the ECU is displaying multiple DTCs and you are unsure where to start, a professional technician can help prioritize and diagnose the issues.

- Intermittent Problems: Intermittent problems can be difficult to diagnose because they do not occur consistently. A professional technician can use advanced data logging and analysis techniques to capture and analyze the problem.

- No DTCs: If the vehicle is experiencing performance problems but the ECU is not displaying any DTCs, it may be a sign of a more complex issue that requires specialized diagnostic skills.

7.2. ECU Reflashing or Programming Needs

Why is professional help essential for reflashing or programming? ECU reflashing and programming should only be performed by trained technicians with the proper tools and knowledge. Incorrectly reflashing the ECU can cause serious damage to the vehicle.

Reasons to Seek Professional Help:

- Specialized Equipment: ECU reflashing and programming require specialized equipment and software.

- Technical Expertise: It is important to have a thorough understanding of the ECU and its software before attempting to reflash or program it.

- Risk of Damage: Incorrectly reflashing the ECU can cause serious damage to the vehicle, potentially requiring costly repairs.

7.3. Concerns About Safety or Technical Expertise

When should safety concerns dictate seeking professional help? If you are uncomfortable working on the vehicle or unsure about your technical abilities, it is always best to seek professional help. Working on electrical systems can be dangerous, and it is important to take precautions to protect yourself and the vehicle.

Reasons to Seek Professional Help:

- Electrical Hazards: Working on electrical systems can expose you to the risk of electric shock.

- Potential Damage to the Vehicle: Incorrectly performing repairs can cause damage to the vehicle, potentially requiring costly repairs.

- Lack of Confidence: If you are not confident in your ability to safely and effectively perform the repairs, it is best to seek professional help.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers professional diagnostic and repair services, as well as training and certification programs for technicians.

8. H22A1 OBD2 ECU: A Comprehensive FAQ

Do you have lingering questions about the H22A1 OBD2 ECU? Here are some frequently asked questions:

- What is the primary function of the H22A1 OBD2 ECU?

- The primary function of the H22A1 OBD2 ECU is to manage the engine’s performance by controlling fuel injection, ignition timing, and other parameters based on sensor inputs.

- How can I check for error codes on my H22A1 OBD2 ECU?

- You can check for error codes using an OBD2 scanner. Plug the scanner into the diagnostic port, turn on the ignition, and follow the scanner’s instructions to read stored DTCs.

- What does it mean when my H22A1 OBD2 ECU throws a P0171 code?

- A P0171 code (System Too Lean, Bank 1) indicates that the engine is running with an insufficient amount of fuel in the air-fuel mixture.

- Can a faulty oxygen sensor affect the performance of my H22A1 OBD2 ECU?

- Yes, a faulty oxygen sensor can provide inaccurate readings, leading the ECU to incorrectly adjust the fuel mixture, affecting performance.

- What are the signs of internal ECU failure in an H22A1 OBD2 ECU?

- Signs include the inability to communicate with the ECU, engine stalling, misfiring, fuel injector problems, and erratic sensor readings.

- How often should I perform a sensor check on my H22A1 OBD2 ECU system?

- It’s recommended to visually inspect sensors and wiring every 3 months, check for stored DTCs every 6 months, and perform a comprehensive sensor test every year.

- Is it safe to reflash the H22A1 OBD2 ECU myself?

- ECU reflashing should only be performed by trained technicians with the proper tools and knowledge, as incorrect reflashing can cause serious damage.

- What tools are essential for diagnosing H22A1 OBD2 ECU problems?

- Essential tools include an OBD2 scanner, multimeter, lab scope, and a smoke machine for detecting vacuum leaks.

- How can CAR-DIAGNOSTIC-TOOL.EDU.VN help with my H22A1 OBD2 ECU issues?

- CAR-DIAGNOSTIC-TOOL.EDU.VN offers advanced diagnostic tools, step-by-step repair guides, expert technical support, and training programs to help resolve ECU issues.

- Can data logging help diagnose intermittent issues with my H22A1 OBD2 ECU?

- Yes, data logging can capture data during the occurrence of an intermittent problem, providing valuable clues about the cause.

9. The Future of H22A1 OBD2 ECU Technology

What innovations are on the horizon for ECU technology? The future of H22A1 OBD2 ECU technology is marked by advancements in diagnostic capabilities, performance enhancements, and integration with modern vehicle systems. As technology evolves, ECUs will become more sophisticated and capable of optimizing engine performance and efficiency.

Emerging Trends:

- Artificial Intelligence (AI): AI is being integrated into ECUs to provide more accurate and adaptive control of engine parameters. AI-powered ECUs can learn from driving patterns and adjust settings in real-time to optimize performance and fuel efficiency.

- Wireless Communication: ECUs are increasingly equipped with wireless communication capabilities, allowing for remote diagnostics, software updates, and integration with cloud-based services.

- Cybersecurity: As vehicles become more connected, cybersecurity is becoming a critical concern. Future ECUs will incorporate advanced security features to protect against hacking and unauthorized access.

- Integration with Advanced Driver Assistance Systems (ADAS): ECUs are being integrated with ADAS to provide more comprehensive control of vehicle systems. This integration allows for features such as adaptive cruise control, lane departure warning, and automatic emergency braking.

According to a report by McKinsey & Company, the market for automotive ECUs is expected to grow by 10% annually over the next decade, driven by the increasing complexity of vehicle systems and the demand for greater performance and efficiency.

10. Maximize Your H22A1 OBD2 ECU Performance with CAR-DIAGNOSTIC-TOOL.EDU.VN

Ready to take control of your H22A1 OBD2 ECU diagnostics and repairs? At CAR-DIAGNOSTIC-TOOL.EDU.VN, we understand the challenges you face as automotive technicians and garage owners. From complex diagnostic procedures to the need for continuous training, we’ve got you covered.

Imagine a world where you can quickly and accurately diagnose any ECU issue, access detailed repair guides at your fingertips, and receive expert support whenever you need it. That’s the promise of CAR-DIAGNOSTIC-TOOL.EDU.VN.

Our comprehensive suite of services includes:

- Advanced Diagnostic Tools: Equip your garage with the latest OBD2 scanners, lab scopes, and data logging equipment to pinpoint issues with ease.

- Step-by-Step Repair Guides: Access our extensive database of repair guides, complete with detailed instructions and diagrams, ensuring you get the job done right the first time.

- Remote Technical Support: Connect with our team of experienced technicians for real-time assistance, troubleshooting, and expert advice, all from the comfort of your garage.

- Technician Training Programs: Enhance your skills with our hands-on training programs, covering everything from basic diagnostics to advanced ECU reflashing and programming.

Don’t let ECU problems slow you down. Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today and discover how we can help you boost your efficiency, increase your profits, and enhance your reputation.

Call us now at +1 (641) 206-8880 or visit our website at CAR-DIAGNOSTIC-TOOL.EDU.VN to schedule a consultation.

Our US support office is located at 1100 Congress Ave, Austin, TX 78701, United States.

Let CAR-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in automotive diagnostics and repair!