A freeze frame generated on an OBD2 vehicle provides valuable insight into the conditions present when a Diagnostic Trouble Code (DTC) is set, assisting in accurate car diagnostics, troubleshooting, and repair, and CAR-DIAGNOSTIC-TOOL.EDU.VN equips you with the resources for effective vehicle maintenance. We offer comprehensive solutions, including advanced diagnostic tools, detailed repair guides, and expert technical support, along with specialized training programs and remote assistance to ensure automotive technicians are well-prepared for any challenge. Contact us via WhatsApp at +1 (641) 206-8880 or visit CAR-DIAGNOSTIC-TOOL.EDU.VN for more information.

Contents

- 1. Understanding Freeze Frame Data in OBD2 Systems

- 1.1. What is Freeze Frame?

- 1.2. Key Parameters Recorded in Freeze Frame

- 1.3. Why is Freeze Frame Important?

- 2. How Freeze Frame Data is Generated

- 2.1. Triggering Events for Freeze Frame

- 2.2. ECU’s Role in Capturing Data

- 2.3. Data Storage and Retrieval

- 3. Interpreting Freeze Frame Data: A Step-by-Step Guide

- 3.1. Connecting an OBD2 Scanner

- 3.2. Retrieving DTCs and Freeze Frame Data

- 3.3. Analyzing Key Parameters

- 3.4. Correlating Data with Symptoms

- 3.5. Utilizing Online Resources

- 3.6. Practical Example

- 4. Common Scenarios Where Freeze Frame is Helpful

- 4.1. Intermittent Issues

- 4.2. Misfire Diagnosis

- 4.3. Emissions Problems

- 4.4. Sensor Failures

- 4.5. Fuel System Issues

- 5. Limitations of Freeze Frame Data

- 5.1. Not a Standalone Solution

- 5.2. Limited Parameters

- 5.3. Data Accuracy

- 5.4. Data Interpretation

- 5.5. Overwriting Data

- 6. Advanced Diagnostic Techniques Using Freeze Frame Data

- 6.1. Graphing and Data Logging

- 6.2. Bi-Directional Controls

- 6.3. Accessing OEM Information

- 6.4. Using a Digital Multimeter (DMM)

- 6.5. Performing a Compression Test

- 7. Freeze Frame Data and OBDLink® App

- 7.1. Enhanced Diagnostics

- 7.2. Online Lookup

- 7.3. Report Generation

- 7.4. PID Values

- 7.5. User-Friendly Interface

- 8. Best Practices for Using Freeze Frame Data

- 8.1. Verify Scanner Compatibility

- 8.2. Retrieve Data Promptly

- 8.3. Document Findings

- 8.4. Perform Additional Tests

- 8.5. Stay Informed

- 9. The Future of Freeze Frame Technology

- 9.1. Advanced Data Analysis

- 9.2. Integration with Other Systems

- 9.3. Improved User Interfaces

- 9.4. Enhanced Security

- 9.5. Over-the-Air Updates

- 10. FAQs About Freeze Frame Data

- 10.1. What is the difference between a DTC and freeze frame data?

- 10.2. Can freeze frame data be cleared without clearing the DTC?

- 10.3. How many freeze frame records can a vehicle store?

- 10.4. Is freeze frame data the same for all vehicles?

- 10.5. Can I use freeze frame data to diagnose ABS or SRS issues?

- 10.6. What does it mean when there is no freeze frame data available?

- 10.7. How accurate is freeze frame data?

- 10.8. Can freeze frame data help me diagnose a catalytic converter issue?

- 10.9. Is freeze frame data useful for diagnosing transmission problems?

- 10.10. Where can I learn more about interpreting freeze frame data?

1. Understanding Freeze Frame Data in OBD2 Systems

Freeze frame data is a snapshot of a vehicle’s operating conditions at the moment a Diagnostic Trouble Code (DTC) is triggered, acting as a crucial tool for automotive technicians and DIY enthusiasts alike.

1.1. What is Freeze Frame?

Freeze frame data is a recording of specific engine parameters at the time a DTC is set, offering a picture of the conditions that led to the fault. According to the Environmental Protection Agency (EPA), OBD2 systems are designed to monitor a vehicle’s emissions control systems, and freeze frame is a key component of this monitoring.

1.2. Key Parameters Recorded in Freeze Frame

The data captured typically includes engine speed (RPM), engine load, coolant temperature, fuel trim, and vehicle speed, although the specific parameters may vary depending on the vehicle manufacturer and the nature of the DTC. A study by the Society of Automotive Engineers (SAE) found that analyzing these parameters together can significantly reduce diagnostic time.

1.3. Why is Freeze Frame Important?

Freeze frame data is useful because it provides context for a DTC. Instead of just knowing that a problem occurred, technicians can see what was happening when the problem occurred. This helps in diagnosing intermittent issues and replicating the conditions that trigger the fault. As highlighted in a research paper from the University of Michigan’s Automotive Research Center, this capability is vital for accurate diagnostics.

2. How Freeze Frame Data is Generated

The generation of freeze frame data is a systematic process initiated by the vehicle’s On-Board Diagnostics (OBD2) system when a fault is detected, capturing essential parameters to aid in diagnosis.

2.1. Triggering Events for Freeze Frame

A freeze frame is typically generated when a DTC related to emissions or engine performance is set. These DTCs are programmed in the vehicle’s Engine Control Unit (ECU) to monitor various sensors and systems. The National Institute for Automotive Service Excellence (ASE) emphasizes that understanding these triggering events is key to interpreting freeze frame data effectively.

2.2. ECU’s Role in Capturing Data

When a triggering event occurs, the ECU captures and stores a set of predefined parameters in its memory. This data represents the operating conditions at the time the fault was detected. A report by the California Air Resources Board (CARB) indicates that the accuracy and reliability of this data are critical for effective emissions control and diagnostics.

2.3. Data Storage and Retrieval

The freeze frame data is stored in the ECU until it is either cleared manually using a scan tool or overwritten by a new DTC. The data can be retrieved using an OBD2 scanner, which reads the stored parameters and displays them for the technician. According to a study by the University of California, Berkeley, modern scan tools provide user-friendly interfaces for accessing and interpreting freeze frame data.

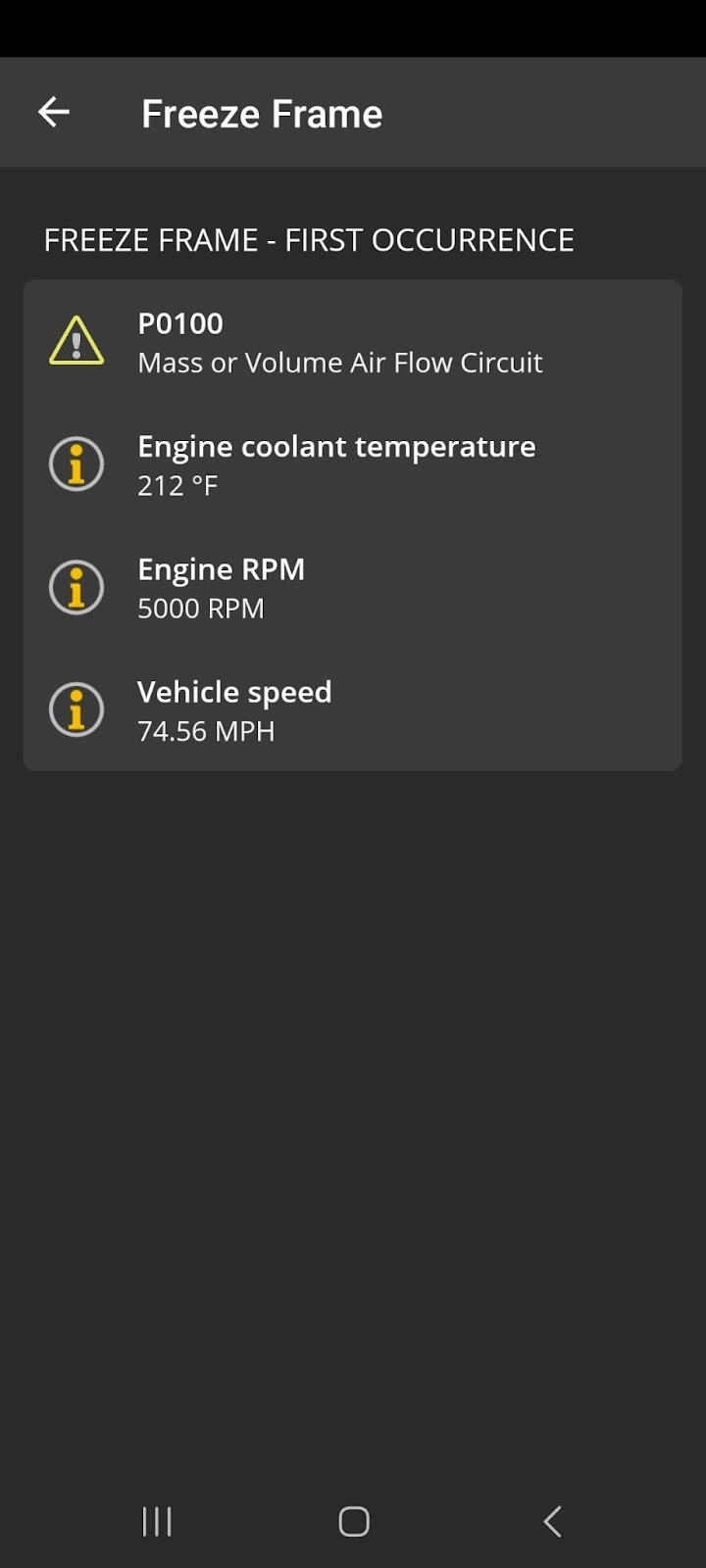

Android screen showing a Freeze Frame report.

Android screen showing a Freeze Frame report.

3. Interpreting Freeze Frame Data: A Step-by-Step Guide

Interpreting freeze frame data involves a systematic approach, combining technical knowledge with practical diagnostic skills to accurately identify the root cause of vehicle issues.

3.1. Connecting an OBD2 Scanner

The first step is to connect an OBD2 scanner to the vehicle’s diagnostic port, typically located under the dashboard. Ensure the vehicle’s ignition is turned on but the engine is off. The OBDLink® app, compatible with OBDLink® adapters, provides enhanced diagnostics, giving you access to modules and parameters beyond the SAE OBD-II standard, like reading and clearing codes for ABS, SRS, and TPMS.

3.2. Retrieving DTCs and Freeze Frame Data

Use the scanner to retrieve the stored DTCs and freeze frame data from the ECU. Most scanners will display the DTCs along with the corresponding freeze frame information. According to the Automotive Management Institute (AMI), using a quality scanner is essential for accurate data retrieval.

3.3. Analyzing Key Parameters

Carefully examine the key parameters recorded in the freeze frame. Look for any values that are outside the normal operating range or that seem inconsistent with the vehicle’s condition. A study by the National Automotive Technology Education Foundation (NATEF) emphasizes the importance of understanding normal parameter ranges for effective diagnostics.

3.4. Correlating Data with Symptoms

Correlate the freeze frame data with the symptoms reported by the driver or observed during inspection. For example, if the DTC indicates a misfire and the freeze frame shows high engine RPM and low coolant temperature, it may suggest a cold start issue. The University of Northwestern Ohio’s automotive program highlights the need to consider the vehicle’s history and maintenance records during this process.

3.5. Utilizing Online Resources

Use online resources, such as technical forums and OEM websites, to research the DTC and freeze frame data. These resources can provide additional information and insights into common causes and troubleshooting steps. As noted by the ASE, staying current with technical information is crucial for automotive technicians. The OBDLink app also offers an Online Lookup feature to read more about DTC definitions.

3.6. Practical Example

Consider a scenario where the DTC is P0171 (System Too Lean, Bank 1) and the freeze frame data shows low fuel trim values and high intake air temperature. This could indicate a vacuum leak or a faulty mass airflow sensor. By analyzing the data and correlating it with the DTC, you can narrow down the potential causes and perform targeted tests.

4. Common Scenarios Where Freeze Frame is Helpful

Freeze frame data is invaluable in diagnosing a wide array of automotive issues, providing specific insights that can significantly streamline the troubleshooting process.

4.1. Intermittent Issues

Freeze frame data is particularly useful for diagnosing intermittent issues that are difficult to replicate. By capturing the conditions present when the fault occurred, technicians can gain valuable clues about the root cause. According to a study by the University of Waterloo’s Centre for Automotive Research, freeze frame data can reduce diagnostic time by up to 40% in such cases.

4.2. Misfire Diagnosis

When diagnosing misfires, freeze frame data can provide insights into engine speed, load, and fuel trim, helping to identify whether the misfire is related to fuel delivery, ignition, or mechanical issues. The American Society of Mechanical Engineers (ASME) highlights the importance of analyzing these parameters in conjunction with other diagnostic tests.

4.3. Emissions Problems

Freeze frame data is essential for diagnosing emissions-related problems, such as those related to the oxygen sensors, catalytic converter, or evaporative emissions system. By examining the data, technicians can determine whether the issue is related to a specific component or a broader system malfunction. The EPA emphasizes the role of freeze frame data in ensuring compliance with emissions standards.

4.4. Sensor Failures

When a sensor fails, freeze frame data can provide information about the sensor’s output at the time of failure, helping to determine whether the sensor is providing inaccurate readings or is completely non-functional. A report by the National Highway Traffic Safety Administration (NHTSA) indicates that accurate sensor data is crucial for vehicle safety systems.

4.5. Fuel System Issues

Freeze frame data can help diagnose fuel system issues, such as lean or rich conditions, by providing information about fuel trim, oxygen sensor readings, and engine load. The Society of Automotive Engineers (SAE) highlights the need to consider these parameters in conjunction with fuel pressure and injector testing.

5. Limitations of Freeze Frame Data

While freeze frame data is a valuable diagnostic tool, it’s important to recognize its limitations to avoid misdiagnosis and ensure accurate troubleshooting.

5.1. Not a Standalone Solution

Freeze frame data should not be used as a standalone diagnostic solution. It provides a snapshot of conditions at a specific moment, but it doesn’t offer a complete picture of the problem. According to the Automotive Management Institute (AMI), freeze frame data should be used in conjunction with other diagnostic tests and information.

5.2. Limited Parameters

The number of parameters recorded in the freeze frame is limited, and not all relevant data may be captured. Depending on the vehicle and the nature of the DTC, some important parameters may be missing, which can hinder the diagnostic process. The National Institute for Automotive Service Excellence (ASE) emphasizes the need to consider these limitations when interpreting freeze frame data.

5.3. Data Accuracy

The accuracy of freeze frame data depends on the accuracy of the sensors and the ECU. If the sensors are faulty or the ECU is malfunctioning, the data may be inaccurate or misleading. A study by the University of Michigan’s Automotive Research Center highlights the importance of verifying sensor accuracy before relying on freeze frame data.

5.4. Data Interpretation

Interpreting freeze frame data requires technical knowledge and experience. Incorrect interpretation can lead to misdiagnosis and unnecessary repairs. According to the Society of Automotive Engineers (SAE), technicians should be properly trained in data interpretation to avoid errors.

5.5. Overwriting Data

Freeze frame data is overwritten when a new DTC is set, which means that valuable information can be lost if the vehicle is driven for an extended period after the initial fault. The California Air Resources Board (CARB) recommends retrieving freeze frame data as soon as possible after a DTC is detected.

6. Advanced Diagnostic Techniques Using Freeze Frame Data

To maximize the effectiveness of freeze frame data, technicians can employ advanced diagnostic techniques that integrate this information with other diagnostic tools and resources.

6.1. Graphing and Data Logging

Using graphing and data logging functions on advanced scan tools can provide a more dynamic view of the vehicle’s performance. By comparing freeze frame data with real-time data, technicians can identify trends and patterns that may not be apparent from a single snapshot. The Automotive Management Institute (AMI) offers courses on advanced diagnostic techniques using graphing and data logging.

6.2. Bi-Directional Controls

Bi-directional controls allow technicians to command specific components to activate or deactivate, which can help isolate the cause of a problem. By using bi-directional controls in conjunction with freeze frame data, technicians can verify the functionality of individual components under specific conditions. The National Institute for Automotive Service Excellence (ASE) emphasizes the importance of understanding bi-directional controls for effective diagnostics.

6.3. Accessing OEM Information

Accessing OEM (Original Equipment Manufacturer) information, such as technical service bulletins (TSBs) and diagnostic procedures, can provide valuable insights into known issues and troubleshooting steps. By comparing freeze frame data with OEM information, technicians can identify common causes and avoid unnecessary repairs. According to the Society of Automotive Engineers (SAE), OEM information is an essential resource for automotive technicians.

6.4. Using a Digital Multimeter (DMM)

A digital multimeter (DMM) can be used to verify the accuracy of sensors and circuits. By comparing freeze frame data with DMM readings, technicians can identify faulty sensors or wiring issues. The University of Northwestern Ohio’s automotive program highlights the need to use a DMM in conjunction with other diagnostic tools.

6.5. Performing a Compression Test

A compression test can help identify mechanical issues, such as worn piston rings or valves. By comparing freeze frame data with compression test results, technicians can determine whether the problem is related to mechanical or electronic issues. The American Society of Mechanical Engineers (ASME) emphasizes the importance of performing a compression test when diagnosing engine problems.

7. Freeze Frame Data and OBDLink® App

The OBDLink® app enhances the use of freeze frame data by providing advanced diagnostic capabilities and user-friendly features, making it easier for technicians and DIY enthusiasts to diagnose and repair vehicle issues.

7.1. Enhanced Diagnostics

The OBDLink® app provides enhanced diagnostics for many vehicle types, allowing access to additional modules and parameters not included in the SAE OBD-II standard. This includes reading and clearing codes for ABS (anti-lock braking system), SRS (supplemental restraint system), and TPMS (tire pressure monitoring system). These enhanced diagnostics provide a more complete picture of the vehicle’s condition when a freeze frame is generated.

7.2. Online Lookup

The app includes an Online Lookup feature that allows users to read more about DTC definitions. By tapping “Online Lookup” on the trouble code information screen, users can access detailed information about the DTC, which can help in interpreting the freeze frame data.

7.3. Report Generation

The OBDLink® app can generate detailed diagnostic reports, including freeze frame data, which can be stored, loaded, and shared. This allows technicians to easily document their findings and share them with customers or other technicians.

7.4. PID Values

The app displays vehicle speed and engine RPM by default, with the ability to add additional PIDs (Parameter IDs) to the display. This allows users to monitor the PIDs that are most relevant to the DTC and freeze frame data.

7.5. User-Friendly Interface

The OBDLink® app has a user-friendly interface that makes it easy to retrieve and interpret freeze frame data. The app is available for both iOS and Android devices, and it is regularly updated with new features and improvements. Download the latest version of the OBDLink app from the App Store (iOS) or Google Play (Android) to take advantage of the updated app’s features and performance.

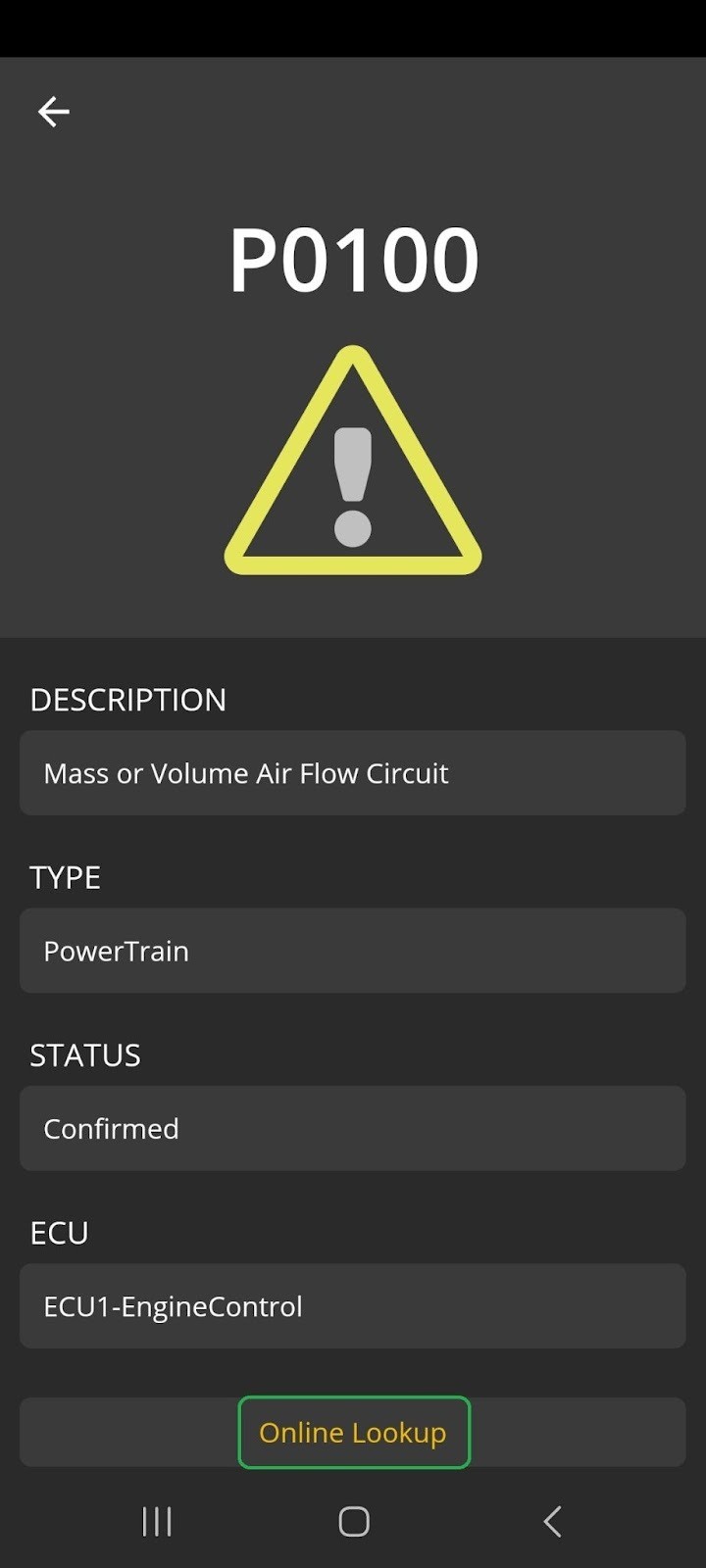

iOS screen showing information about the P0100 trouble code. The Online Lookup button is highlighted.

iOS screen showing information about the P0100 trouble code. The Online Lookup button is highlighted.

8. Best Practices for Using Freeze Frame Data

To ensure the effective use of freeze frame data, it’s important to follow best practices that promote accurate diagnosis and efficient troubleshooting.

8.1. Verify Scanner Compatibility

Before using an OBD2 scanner, verify that it is compatible with the vehicle’s make, model, and year. Some scanners may not support all vehicles or may not provide accurate data. The Automotive Management Institute (AMI) recommends using a high-quality scanner that is regularly updated with the latest software.

8.2. Retrieve Data Promptly

Retrieve freeze frame data as soon as possible after a DTC is detected. The longer the vehicle is driven after the fault, the greater the chance that the data will be overwritten. The National Institute for Automotive Service Excellence (ASE) emphasizes the importance of prompt data retrieval.

8.3. Document Findings

Document all findings, including the DTC, freeze frame data, and any other relevant information. This will help track progress and avoid repeating tests. The University of Northwestern Ohio’s automotive program highlights the need to maintain accurate records of all diagnostic procedures.

8.4. Perform Additional Tests

Perform additional tests to verify the accuracy of the freeze frame data and isolate the cause of the problem. This may include visual inspections, sensor testing, and component testing. The American Society of Mechanical Engineers (ASME) recommends using a combination of diagnostic tools and techniques.

8.5. Stay Informed

Stay informed about the latest diagnostic techniques and tools. The automotive industry is constantly evolving, and it’s important to keep up with the latest advancements. The Society of Automotive Engineers (SAE) offers resources and training programs for automotive technicians.

9. The Future of Freeze Frame Technology

The future of freeze frame technology is likely to involve more advanced data analysis, integration with other vehicle systems, and improved user interfaces.

9.1. Advanced Data Analysis

Future freeze frame systems may incorporate advanced data analysis algorithms that can automatically identify patterns and anomalies in the data. This could help technicians diagnose problems more quickly and accurately. The University of California, Berkeley’s AI Research Lab is working on developing such algorithms for automotive diagnostics.

9.2. Integration with Other Systems

Freeze frame technology may become more integrated with other vehicle systems, such as telematics and cloud-based diagnostic platforms. This could allow technicians to remotely monitor vehicle performance and diagnose problems before they become serious. The National Highway Traffic Safety Administration (NHTSA) is exploring the use of telematics data for vehicle safety and maintenance.

9.3. Improved User Interfaces

Future scan tools may feature more intuitive user interfaces that make it easier to retrieve and interpret freeze frame data. This could include augmented reality displays and voice-activated controls. The Automotive Management Institute (AMI) offers courses on using advanced scan tools with improved user interfaces.

9.4. Enhanced Security

As vehicles become more connected, security is a growing concern. Future freeze frame systems may incorporate enhanced security features to prevent unauthorized access to vehicle data. The Society of Automotive Engineers (SAE) is working on developing security standards for automotive diagnostic systems.

9.5. Over-the-Air Updates

Future freeze frame systems may support over-the-air (OTA) updates, which would allow technicians to update the software and firmware on their scan tools without having to physically connect to a computer. This would make it easier to keep the tools up-to-date and take advantage of the latest features and improvements. The California Air Resources Board (CARB) is promoting the use of OTA updates for vehicle emissions control systems.

10. FAQs About Freeze Frame Data

Here are some frequently asked questions about freeze frame data, covering various aspects of its use and interpretation.

10.1. What is the difference between a DTC and freeze frame data?

A DTC (Diagnostic Trouble Code) is a code that indicates a specific fault in the vehicle’s system, while freeze frame data is a snapshot of the vehicle’s operating conditions at the time the DTC was set.

10.2. Can freeze frame data be cleared without clearing the DTC?

No, freeze frame data is typically cleared when the DTC is cleared. They are linked together in the vehicle’s computer system.

10.3. How many freeze frame records can a vehicle store?

Most vehicles store only one freeze frame record per DTC. Once a new DTC is triggered, the old freeze frame data is overwritten.

10.4. Is freeze frame data the same for all vehicles?

No, the specific parameters recorded in the freeze frame may vary depending on the vehicle’s make, model, and year, as well as the nature of the DTC.

10.5. Can I use freeze frame data to diagnose ABS or SRS issues?

Yes, if the DTC is related to ABS (Anti-lock Braking System) or SRS (Supplemental Restraint System), the freeze frame data can provide valuable information about the conditions present when the fault occurred. The OBDLink® app provides enhanced diagnostics for these systems.

10.6. What does it mean when there is no freeze frame data available?

If there is no freeze frame data available, it may mean that the DTC was not severe enough to trigger the freeze frame, or that the vehicle’s system does not support freeze frame for that particular DTC.

10.7. How accurate is freeze frame data?

The accuracy of freeze frame data depends on the accuracy of the sensors and the ECU. If the sensors are faulty or the ECU is malfunctioning, the data may be inaccurate.

10.8. Can freeze frame data help me diagnose a catalytic converter issue?

Yes, freeze frame data can provide valuable information about the conditions present when a catalytic converter-related DTC is set, such as oxygen sensor readings and engine load.

10.9. Is freeze frame data useful for diagnosing transmission problems?

Yes, if the DTC is related to the transmission, the freeze frame data can provide information about the transmission temperature, speed, and gear position at the time of the fault.

10.10. Where can I learn more about interpreting freeze frame data?

You can learn more about interpreting freeze frame data from online resources, technical forums, OEM websites, and training programs offered by organizations such as the Automotive Management Institute (AMI) and the National Institute for Automotive Service Excellence (ASE). CAR-DIAGNOSTIC-TOOL.EDU.VN also provides resources, including diagnostic tools, repair guides, and technical support.

Understanding and utilizing freeze frame data is crucial for efficient and accurate vehicle diagnostics. CAR-DIAGNOSTIC-TOOL.EDU.VN is dedicated to providing you with the tools and knowledge necessary to excel in automotive repair. Our comprehensive solutions include advanced diagnostic tools, detailed repair guides, and expert technical support.

We also offer specialized training programs and remote assistance to ensure automotive technicians are well-prepared for any challenge. Whether you’re a seasoned professional or just starting out, our resources will help you streamline your workflow, improve accuracy, and enhance customer satisfaction.

Ready to take your diagnostic skills to the next level? Contact us via WhatsApp at +1 (641) 206-8880 or visit CAR-DIAGNOSTIC-TOOL.EDU.VN to explore our range of products and services. Our expert team is here to assist you with any questions and provide tailored solutions to meet your specific needs. Don’t miss out on the opportunity to revolutionize your automotive repair process with CAR-DIAGNOSTIC-TOOL.EDU.VN.