The 2008 Dodge 2500 Obd2 Harness is your gateway to diagnosing and resolving vehicle issues, and at CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide the resources you need, including diagnostic tools, repair guides, and technical support, to effectively use it. Whether you are dealing with error code interpretation, wiring issues, or module communication problems, our offerings ensure you can pinpoint and fix problems efficiently, enhancing your diagnostic capabilities and repair accuracy. Our comprehensive platform at CAR-DIAGNOSTIC-TOOL.EDU.VN supports ongoing professional development through expert-led courses and remote assistance, ensuring you stay at the forefront of automotive technology. Connect with us on WhatsApp at +1 (641) 206-8880, visit our website, or visit our office at 1100 Congress Ave, Austin, TX 78701, United States, to learn more about how we can support your diagnostic and repair needs.

Contents

- 1. Understanding the 2008 Dodge 2500 OBD2 Harness

- 1.1 What is the OBD2 Harness?

- 1.2 Why is the OBD2 Harness Important for Diagnostics?

- 1.3 Key Components of the 2008 Dodge 2500 OBD2 Harness

- 1.4 Common Issues with the OBD2 Harness

- 1.5 How to Inspect the OBD2 Harness for Damage

- 2. Diagnostic Tools for the 2008 Dodge 2500 OBD2 Harness

- 2.1 Basic OBD2 Scanners

- 2.2 Advanced Diagnostic Scanners

- 2.3 Multimeters

- 2.4 Wiring Diagrams and Service Manuals

- 2.5 Oscilloscopes

- 3. Step-by-Step Guide to Diagnosing OBD2 Harness Issues

- 3.1 Initial Inspection

- 3.2 Reading Diagnostic Trouble Codes (DTCs)

- 3.3 Testing for Power and Ground

- 3.4 Checking Continuity of Wires

- 3.5 Performing Component Tests

- 4. Common DTCs Related to the OBD2 Harness

- 4.1 U0001 – High-Speed CAN Communication Bus

- 4.2 U0100 – Lost Communication With ECM/PCM

- 4.3 P0606 – ECM/PCM Processor Fault

- 4.4 B1000 – ECU Internal Failure

- 4.5 U1000 – Class 2 Data Link Malfunction

- 5. Repairing the 2008 Dodge 2500 OBD2 Harness

- 5.1 Replacing Damaged Connectors

- 5.2 Repairing Damaged Wiring

- 5.3 Cleaning Corroded Connections

- 5.4 Replacing the Entire OBD2 Harness

- 5.5 Verifying the Repair

- 6. Preventing Future OBD2 Harness Issues

- 6.1 Regular Inspections

- 6.2 Keeping Connections Clean and Dry

- 6.3 Protecting Wiring from Damage

- 6.4 Avoiding Overloading the OBD2 Port

- 6.5 Addressing Issues Promptly

- 7. The Role of CAR-DIAGNOSTIC-TOOL.EDU.VN in OBD2 Harness Diagnostics and Repair

- 7.1 Comprehensive Diagnostic Tools and Equipment

- 7.2 Detailed Repair Guides and Resources

- 7.3 Expert Technical Support

- 7.4 Training Programs and Workshops

- 7.5 Community Forum and Knowledge Base

- 8. Real-World Examples of OBD2 Harness Issues in the 2008 Dodge 2500

- 8.1 Case Study 1: Intermittent Loss of Communication with ECM

- 8.2 Case Study 2: ABS Fault Due to Wiring Damage

- 8.3 Case Study 3: Transmission Issues Caused by Corroded OBD2 Port

- 8.4 Case Study 4: Airbag System Failure Due to Connector Damage

- 9. Frequently Asked Questions (FAQ) about the 2008 Dodge 2500 OBD2 Harness

- 9.1 What is the OBD2 port used for in a 2008 Dodge 2500?

- 9.2 Where is the OBD2 port located in a 2008 Dodge 2500?

- 9.3 How do I read diagnostic trouble codes (DTCs) from my 2008 Dodge 2500?

- 9.4 What does it mean if my OBD2 scanner won’t connect to my 2008 Dodge 2500?

- 9.5 Can a faulty OBD2 harness cause my check engine light to come on?

- 9.6 How can I test the OBD2 harness for damage?

- 9.7 What are some common DTCs related to the OBD2 harness in a 2008 Dodge 2500?

- 9.8 Can I repair the OBD2 harness myself, or do I need to take it to a professional?

- 9.9 What tools do I need to diagnose and repair OBD2 harness issues?

- 9.10 Where can I find reliable information and support for diagnosing and repairing OBD2 harness issues in my 2008 Dodge 2500?

- 10. Call to Action: Get Expert Assistance with Your 2008 Dodge 2500 OBD2 Harness Today

1. Understanding the 2008 Dodge 2500 OBD2 Harness

The OBD2 (On-Board Diagnostics II) harness in a 2008 Dodge 2500 serves as a critical interface for accessing the vehicle’s computer systems. It allows technicians to read diagnostic trouble codes (DTCs), monitor real-time data, and perform tests to diagnose and repair issues.

1.1 What is the OBD2 Harness?

The OBD2 harness is a standardized wiring system connecting the OBD2 port to various electronic control units (ECUs) within the vehicle. These ECUs manage different systems, including the engine, transmission, ABS, and airbags. The harness ensures data transmission between these systems and diagnostic tools, facilitating accurate diagnostics.

1.2 Why is the OBD2 Harness Important for Diagnostics?

The OBD2 harness is vital because it provides a standardized way to access vehicle data. According to the Environmental Protection Agency (EPA), all vehicles sold in the United States since 1996 are required to have an OBD2 system. This standardization ensures that any compatible scan tool can read data from any vehicle, simplifying diagnostics and repair processes.

1.3 Key Components of the 2008 Dodge 2500 OBD2 Harness

Understanding the components of the OBD2 harness is crucial for effective diagnostics. Key components include:

- OBD2 Port: A 16-pin connector located in the passenger compartment, usually under the dashboard.

- Wiring: A network of wires connecting the OBD2 port to various ECUs.

- Connectors: Plugs that ensure secure connections between the wiring and the ECUs.

1.4 Common Issues with the OBD2 Harness

Several issues can arise with the OBD2 harness, impacting its functionality:

- Corrosion: Exposure to moisture and environmental factors can cause corrosion on the connectors and wiring.

- Damage: Physical damage to the wiring from accidents or wear and tear can disrupt communication.

- Loose Connections: Over time, connections can loosen, leading to intermittent or complete loss of communication.

- Short Circuits: Faulty wiring can cause short circuits, damaging the harness and potentially the ECUs.

1.5 How to Inspect the OBD2 Harness for Damage

Inspecting the OBD2 harness for damage involves a systematic approach:

- Visual Inspection: Check the OBD2 port and wiring for any visible signs of damage, such as cracks, corrosion, or exposed wires.

- Connectivity Check: Ensure the OBD2 port is securely connected and free from debris.

- Wiring Test: Use a multimeter to test the continuity of the wires, ensuring they are not broken or shorted.

Regular inspections can help identify and address issues early, preventing more significant problems down the road.

2. Diagnostic Tools for the 2008 Dodge 2500 OBD2 Harness

Selecting the right diagnostic tools is essential for accurately diagnosing and repairing issues related to the 2008 Dodge 2500 OBD2 harness. Here are some of the most effective tools:

2.1 Basic OBD2 Scanners

Basic OBD2 scanners are entry-level tools that read and clear diagnostic trouble codes (DTCs). They are user-friendly and provide essential information for troubleshooting common issues.

- Features:

- Read and clear DTCs

- Display freeze frame data

- Retrieve VIN (Vehicle Identification Number)

- Benefits:

- Affordable

- Easy to use

- Suitable for basic diagnostics

2.2 Advanced Diagnostic Scanners

Advanced diagnostic scanners offer more comprehensive features, allowing technicians to perform in-depth diagnostics. These scanners often include bi-directional control, live data streaming, and advanced system tests.

- Features:

- Bi-directional control

- Live data streaming

- Advanced system tests (e.g., ABS, SRS)

- Module programming

- Benefits:

- Detailed diagnostics

- Ability to perform system tests

- Module programming capabilities

2.3 Multimeters

Multimeters are indispensable tools for testing the electrical integrity of the OBD2 harness. They can measure voltage, current, and resistance, helping identify wiring issues.

- Features:

- Measure voltage, current, and resistance

- Continuity testing

- Diode testing

- Benefits:

- Essential for electrical diagnostics

- Accurate measurements

- Versatile tool for various applications

2.4 Wiring Diagrams and Service Manuals

Wiring diagrams and service manuals provide detailed information about the OBD2 harness wiring, connector locations, and troubleshooting procedures. These resources are invaluable for accurate diagnostics and repairs.

- Features:

- Detailed wiring diagrams

- Connector locations

- Troubleshooting procedures

- Benefits:

- Accurate information

- Step-by-step guidance

- Reduces guesswork

2.5 Oscilloscopes

Oscilloscopes are advanced tools that display electrical signals as waveforms. They are useful for diagnosing intermittent issues and analyzing signal patterns in the OBD2 harness.

- Features:

- Display electrical signals as waveforms

- Capture intermittent issues

- Analyze signal patterns

- Benefits:

- Advanced diagnostics

- Identification of intermittent problems

- Detailed signal analysis

Using a combination of these diagnostic tools ensures accurate and efficient troubleshooting of OBD2 harness issues in the 2008 Dodge 2500. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we offer training and support to help you master these tools and techniques.

3. Step-by-Step Guide to Diagnosing OBD2 Harness Issues

Diagnosing issues with the 2008 Dodge 2500 OBD2 harness requires a systematic approach. Follow these steps to accurately identify and resolve problems.

3.1 Initial Inspection

Begin with a thorough visual inspection of the OBD2 port and harness. Look for any signs of damage, corrosion, or loose connections.

- Check the OBD2 Port: Ensure the port is clean and free from debris. Verify that the pins are not bent or damaged.

- Inspect the Wiring: Look for any cuts, cracks, or exposed wires along the harness.

- Examine Connectors: Check the connectors for corrosion or loose connections.

3.2 Reading Diagnostic Trouble Codes (DTCs)

Use an OBD2 scanner to read any stored DTCs. These codes provide valuable information about the nature and location of the problem.

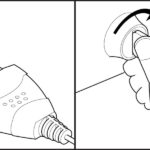

- Connect the Scanner: Plug the OBD2 scanner into the OBD2 port.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Read DTCs: Follow the scanner’s instructions to read and record any DTCs.

- Interpret the Codes: Use a service manual or online database to interpret the meaning of each DTC.

3.3 Testing for Power and Ground

Ensure that the OBD2 port is receiving power and ground. Use a multimeter to test the voltage and continuity.

- Locate Power and Ground Pins: Refer to a wiring diagram to identify the power and ground pins on the OBD2 port.

- Test for Power: With the ignition on, use a multimeter to measure the voltage between the power pin and ground. A reading of 12V is expected.

- Test for Ground: Use a multimeter to test the continuity between the ground pin and a known good ground point on the vehicle.

3.4 Checking Continuity of Wires

Test the continuity of each wire in the OBD2 harness to ensure there are no breaks or shorts.

- Disconnect the Battery: Disconnect the negative battery cable to prevent electrical damage.

- Identify the Wires: Refer to a wiring diagram to identify the wires connected to the OBD2 port.

- Test Continuity: Use a multimeter to test the continuity of each wire, checking for continuity between the OBD2 port and the corresponding ECU connector.

3.5 Performing Component Tests

If specific components are suspected, perform component tests using an advanced diagnostic scanner.

- Connect the Scanner: Plug the advanced diagnostic scanner into the OBD2 port.

- Access Component Tests: Follow the scanner’s instructions to access component tests for the suspected components.

- Perform Tests: Perform the tests and interpret the results according to the scanner’s instructions.

By following these steps, you can systematically diagnose and resolve issues with the 2008 Dodge 2500 OBD2 harness. CAR-DIAGNOSTIC-TOOL.EDU.VN offers detailed guides and technical support to assist you at every stage of the diagnostic process.

4. Common DTCs Related to the OBD2 Harness

Diagnostic Trouble Codes (DTCs) provide critical information for diagnosing issues with the 2008 Dodge 2500 OBD2 harness. Here are some common DTCs and their potential causes:

4.1 U0001 – High-Speed CAN Communication Bus

This code indicates a communication failure on the high-speed CAN (Controller Area Network) bus.

- Possible Causes:

- Faulty ECU

- Wiring issues in the CAN bus

- Loose connections

- Troubleshooting Steps:

- Inspect CAN bus wiring for damage.

- Check connections at each ECU.

- Test CAN bus resistance.

4.2 U0100 – Lost Communication With ECM/PCM

This code indicates a loss of communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM).

- Possible Causes:

- Faulty ECM/PCM

- Wiring issues between ECM/PCM and OBD2 port

- Power supply issues to ECM/PCM

- Troubleshooting Steps:

- Check power and ground to ECM/PCM.

- Inspect wiring for damage.

- Test continuity of communication wires.

4.3 P0606 – ECM/PCM Processor Fault

This code indicates an internal fault in the ECM/PCM processor.

- Possible Causes:

- Faulty ECM/PCM

- Software issues

- Troubleshooting Steps:

- Check for software updates.

- Inspect ECM/PCM for physical damage.

- Replace ECM/PCM if necessary.

4.4 B1000 – ECU Internal Failure

This code indicates an internal failure within an ECU.

- Possible Causes:

- Faulty ECU

- Software issues

- Troubleshooting Steps:

- Check for software updates.

- Inspect ECU for physical damage.

- Replace ECU if necessary.

4.5 U1000 – Class 2 Data Link Malfunction

This code indicates a malfunction in the Class 2 data link.

- Possible Causes:

- Wiring issues in the data link

- Faulty module on the data link

- Troubleshooting Steps:

- Inspect wiring for damage.

- Check connections at each module.

- Test data link resistance.

Understanding these common DTCs and their potential causes is crucial for efficient diagnostics. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive resources and training to help you interpret DTCs accurately and resolve issues effectively.

5. Repairing the 2008 Dodge 2500 OBD2 Harness

Repairing the 2008 Dodge 2500 OBD2 harness involves addressing specific issues identified during the diagnostic process. Here are some common repair procedures:

5.1 Replacing Damaged Connectors

Damaged connectors can cause poor connections and communication failures. Replacing them can restore proper functionality.

- Identify Damaged Connector: Locate the damaged connector on the OBD2 harness.

- Disconnect the Connector: Disconnect the connector from the wiring.

- Cut the Wires: Cut the wires close to the connector, leaving enough length for splicing.

- Strip the Wires: Strip the insulation from the ends of the wires.

- Splice the Wires: Use butt connectors or solder to splice the wires to the new connector.

- Secure the Connections: Use heat shrink tubing to insulate and protect the connections.

- Connect the New Connector: Connect the new connector to the wiring harness.

5.2 Repairing Damaged Wiring

Damaged wiring can cause short circuits or open circuits. Repairing the wiring can restore proper communication.

- Identify Damaged Wire: Locate the damaged wire on the OBD2 harness.

- Cut the Wire: Cut the wire at the point of damage.

- Strip the Wires: Strip the insulation from the ends of the wires.

- Splice the Wires: Use butt connectors or solder to splice the wires together.

- Insulate the Connection: Use heat shrink tubing to insulate and protect the connection.

5.3 Cleaning Corroded Connections

Corrosion can cause poor connections and communication failures. Cleaning corroded connections can improve conductivity.

- Disconnect the Connector: Disconnect the corroded connector.

- Apply Cleaning Solution: Apply a specialized electrical contact cleaner to the corroded pins.

- Scrub the Pins: Use a small brush or contact cleaner tool to scrub the pins and remove corrosion.

- Rinse the Connector: Rinse the connector with clean water and dry it thoroughly.

- Apply Dielectric Grease: Apply a small amount of dielectric grease to the pins to prevent future corrosion.

- Reconnect the Connector: Reconnect the connector to the wiring harness.

5.4 Replacing the Entire OBD2 Harness

In cases of extensive damage, replacing the entire OBD2 harness may be necessary.

- Disconnect the Battery: Disconnect the negative battery cable to prevent electrical damage.

- Locate the Harness: Locate the OBD2 harness and its connections to the ECUs.

- Disconnect the Connectors: Disconnect all connectors from the ECUs.

- Remove the Harness: Carefully remove the old OBD2 harness from the vehicle.

- Install the New Harness: Install the new OBD2 harness, connecting all connectors to the ECUs.

- Reconnect the Battery: Reconnect the negative battery cable.

5.5 Verifying the Repair

After performing any repair, it is essential to verify that the issue has been resolved.

- Read DTCs: Use an OBD2 scanner to read any stored DTCs.

- Clear DTCs: Clear any DTCs that are related to the repaired issue.

- Test the System: Perform system tests to ensure that all components are functioning correctly.

By following these repair procedures, you can effectively address issues with the 2008 Dodge 2500 OBD2 harness. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed repair guides and expert technical support to help you through every step of the process.

6. Preventing Future OBD2 Harness Issues

Preventing future issues with the 2008 Dodge 2500 OBD2 harness involves regular maintenance and proactive measures. Here are some tips to keep your OBD2 harness in good condition:

6.1 Regular Inspections

Perform regular visual inspections of the OBD2 port and harness to identify any signs of damage or corrosion.

- Frequency: Inspect the OBD2 harness at least every six months or during routine maintenance.

- What to Look For: Check for cracks, corrosion, loose connections, and exposed wires.

6.2 Keeping Connections Clean and Dry

Moisture and contaminants can cause corrosion and poor connections. Keep the OBD2 port and connectors clean and dry.

- Cleaning Procedure: Use a specialized electrical contact cleaner to clean the pins and connectors.

- Drying Procedure: Dry the connectors thoroughly after cleaning.

- Application of Dielectric Grease: Apply a small amount of dielectric grease to the pins to prevent future corrosion.

6.3 Protecting Wiring from Damage

Protect the OBD2 harness wiring from physical damage by routing it away from sharp edges and moving parts.

- Routing: Ensure the wiring is properly routed and secured with clips or ties.

- Protection: Use protective sleeves or conduit to shield the wiring from abrasion and impact.

6.4 Avoiding Overloading the OBD2 Port

Avoid overloading the OBD2 port with multiple devices or accessories, as this can cause damage to the port and harness.

- Usage: Use only approved and compatible devices with the OBD2 port.

- Power Consumption: Ensure that devices connected to the OBD2 port do not draw excessive power.

6.5 Addressing Issues Promptly

Address any issues with the OBD2 harness promptly to prevent further damage and complications.

- Early Detection: Monitor the vehicle for any signs of OBD2 harness issues, such as communication failures or DTCs.

- Prompt Repairs: Perform necessary repairs as soon as possible to prevent minor issues from escalating into major problems.

By following these preventive measures, you can minimize the risk of future issues with the 2008 Dodge 2500 OBD2 harness. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive resources and support to help you maintain your vehicle’s diagnostic system effectively.

7. The Role of CAR-DIAGNOSTIC-TOOL.EDU.VN in OBD2 Harness Diagnostics and Repair

CAR-DIAGNOSTIC-TOOL.EDU.VN plays a crucial role in supporting technicians and vehicle owners with OBD2 harness diagnostics and repair. We offer a range of services and resources to help you effectively troubleshoot and resolve issues.

7.1 Comprehensive Diagnostic Tools and Equipment

We provide a wide selection of diagnostic tools and equipment, including OBD2 scanners, multimeters, oscilloscopes, and wiring diagrams. Our tools are designed to meet the needs of both professional technicians and DIY enthusiasts.

- Selection: We offer a variety of tools from leading manufacturers, ensuring quality and reliability.

- Support: Our team can help you select the right tools for your specific needs and provide training on their proper use.

7.2 Detailed Repair Guides and Resources

We offer detailed repair guides and resources that provide step-by-step instructions for diagnosing and repairing OBD2 harness issues. Our guides are written by experienced technicians and include clear diagrams and illustrations.

- Coverage: Our guides cover a wide range of issues, from basic troubleshooting to advanced repairs.

- Accessibility: Our resources are available online, allowing you to access them anytime, anywhere.

7.3 Expert Technical Support

Our team of expert technicians is available to provide technical support and assistance. Whether you have a question about a diagnostic procedure or need help interpreting DTCs, we are here to help.

- Availability: Our technical support team is available via phone, email, and online chat.

- Expertise: Our technicians have extensive experience in OBD2 harness diagnostics and repair.

7.4 Training Programs and Workshops

We offer training programs and workshops designed to enhance your diagnostic and repair skills. Our programs cover a wide range of topics, including OBD2 system operation, DTC interpretation, and advanced diagnostic techniques.

- Curriculum: Our programs are developed by industry experts and are designed to provide practical, hands-on training.

- Certification: Upon completion of our programs, you will receive a certification that demonstrates your expertise in OBD2 harness diagnostics and repair.

7.5 Community Forum and Knowledge Base

Our online community forum and knowledge base provide a platform for technicians and vehicle owners to share information, ask questions, and collaborate on diagnostic and repair issues.

- Collaboration: Our community forum allows you to connect with other professionals and share your experiences.

- Knowledge Sharing: Our knowledge base contains a wealth of information on OBD2 harness diagnostics and repair.

At CAR-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing the tools, resources, and support you need to effectively diagnose and repair OBD2 harness issues. Contact us today to learn more about our services and how we can help you.

8. Real-World Examples of OBD2 Harness Issues in the 2008 Dodge 2500

To illustrate the importance of proper OBD2 harness diagnostics and repair, here are some real-world examples of issues encountered in the 2008 Dodge 2500:

8.1 Case Study 1: Intermittent Loss of Communication with ECM

- Symptoms: The vehicle experienced intermittent loss of communication with the ECM, resulting in stalling and difficulty starting.

- Diagnosis:

- An OBD2 scanner revealed a U0100 code (Lost Communication with ECM/PCM).

- A visual inspection revealed corrosion on the ECM connector.

- Continuity testing confirmed a break in the communication wire between the OBD2 port and ECM.

- Repair:

- The corroded ECM connector was cleaned and treated with dielectric grease.

- The damaged communication wire was repaired by splicing in a new section of wire.

- Outcome: The issue was resolved, and the vehicle no longer experienced loss of communication with the ECM.

8.2 Case Study 2: ABS Fault Due to Wiring Damage

- Symptoms: The ABS (Anti-lock Braking System) light was illuminated, and the ABS was not functioning properly.

- Diagnosis:

- An OBD2 scanner revealed a C0031 code (Left Front Wheel Speed Sensor Circuit Malfunction).

- A visual inspection revealed damage to the wiring harness near the left front wheel speed sensor.

- Continuity testing confirmed an open circuit in the wheel speed sensor wire.

- Repair:

- The damaged wiring harness was repaired by replacing the damaged section of wire.

- The wheel speed sensor was tested and found to be functioning properly.

- Outcome: The issue was resolved, and the ABS system returned to normal operation.

8.3 Case Study 3: Transmission Issues Caused by Corroded OBD2 Port

- Symptoms: The vehicle experienced erratic shifting and transmission slipping.

- Diagnosis:

- An OBD2 scanner revealed a P0700 code (Transmission Control System Malfunction).

- A visual inspection revealed corrosion on the OBD2 port pins.

- Communication with the transmission control module (TCM) was intermittent.

- Repair:

- The OBD2 port was cleaned and treated with electrical contact cleaner.

- Dielectric grease was applied to the pins to prevent future corrosion.

- Outcome: The issue was resolved, and the transmission returned to normal operation.

8.4 Case Study 4: Airbag System Failure Due to Connector Damage

- Symptoms: The airbag warning light was illuminated, and the airbag system was not functioning properly.

- Diagnosis:

- An OBD2 scanner revealed a B0001 code (Driver Airbag Circuit Open).

- A visual inspection revealed damage to the connector for the driver’s side airbag.

- Continuity testing confirmed an open circuit in the airbag circuit.

- Repair:

- The damaged connector was replaced with a new connector.

- The airbag system was tested to ensure proper operation.

- Outcome: The issue was resolved, and the airbag system returned to normal operation.

These real-world examples highlight the importance of thorough diagnostics and proper repair techniques when dealing with OBD2 harness issues in the 2008 Dodge 2500. CAR-DIAGNOSTIC-TOOL.EDU.VN provides the resources and support you need to effectively address these types of issues and ensure the safety and reliability of your vehicle.

9. Frequently Asked Questions (FAQ) about the 2008 Dodge 2500 OBD2 Harness

Here are some frequently asked questions about the 2008 Dodge 2500 OBD2 harness, along with detailed answers to help you understand and address common issues:

9.1 What is the OBD2 port used for in a 2008 Dodge 2500?

The OBD2 port in a 2008 Dodge 2500 is used to access the vehicle’s computer systems for diagnostics and monitoring. It allows technicians to read diagnostic trouble codes (DTCs), monitor real-time data, and perform tests to diagnose and repair issues.

9.2 Where is the OBD2 port located in a 2008 Dodge 2500?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle. Look for a 16-pin connector, usually near the steering column or center console.

9.3 How do I read diagnostic trouble codes (DTCs) from my 2008 Dodge 2500?

To read DTCs, you need an OBD2 scanner. Plug the scanner into the OBD2 port, turn the ignition to the “ON” position (without starting the engine), and follow the scanner’s instructions to read and record any stored DTCs.

9.4 What does it mean if my OBD2 scanner won’t connect to my 2008 Dodge 2500?

If your OBD2 scanner won’t connect, it could indicate a problem with the OBD2 port, the wiring harness, or the vehicle’s computer systems. Check the OBD2 port for damage or corrosion, and test the power and ground connections.

9.5 Can a faulty OBD2 harness cause my check engine light to come on?

Yes, a faulty OBD2 harness can cause the check engine light to come on. Issues such as damaged wiring, corroded connections, or loose pins can disrupt communication between the vehicle’s computer systems and trigger the check engine light.

9.6 How can I test the OBD2 harness for damage?

You can test the OBD2 harness for damage by performing a visual inspection and using a multimeter to test the continuity of the wires. Look for any signs of damage, such as cracks, corrosion, or exposed wires. Use the multimeter to check for breaks or shorts in the wiring.

9.7 What are some common DTCs related to the OBD2 harness in a 2008 Dodge 2500?

Some common DTCs related to the OBD2 harness include U0001 (High-Speed CAN Communication Bus), U0100 (Lost Communication With ECM/PCM), and B1000 (ECU Internal Failure). These codes indicate communication or system failures that may be related to the OBD2 harness.

9.8 Can I repair the OBD2 harness myself, or do I need to take it to a professional?

Whether you can repair the OBD2 harness yourself depends on your experience and the extent of the damage. Simple repairs, such as cleaning corroded connections or replacing damaged connectors, can often be done by DIY enthusiasts. However, more complex repairs, such as repairing damaged wiring or replacing the entire harness, may require professional expertise.

9.9 What tools do I need to diagnose and repair OBD2 harness issues?

To diagnose and repair OBD2 harness issues, you will need an OBD2 scanner, a multimeter, wiring diagrams, and basic hand tools. Advanced diagnostic tools, such as oscilloscopes, may be helpful for diagnosing intermittent issues.

9.10 Where can I find reliable information and support for diagnosing and repairing OBD2 harness issues in my 2008 Dodge 2500?

You can find reliable information and support at CAR-DIAGNOSTIC-TOOL.EDU.VN. We offer comprehensive diagnostic tools, detailed repair guides, expert technical support, and training programs to help you effectively troubleshoot and resolve OBD2 harness issues.

These FAQs provide valuable information for understanding and addressing common issues related to the 2008 Dodge 2500 OBD2 harness. CAR-DIAGNOSTIC-TOOL.EDU.VN is your trusted resource for all your diagnostic and repair needs.

10. Call to Action: Get Expert Assistance with Your 2008 Dodge 2500 OBD2 Harness Today

Are you experiencing issues with your 2008 Dodge 2500 OBD2 harness? Don’t let diagnostic challenges slow you down. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide the tools, resources, and expert support you need to diagnose and repair OBD2 harness issues efficiently and effectively.

- Comprehensive Solutions: From diagnostic tools and detailed repair guides to expert technical support and training programs, we offer comprehensive solutions tailored to your needs.

- Expert Assistance: Our team of experienced technicians is available to provide guidance and assistance every step of the way, ensuring accurate diagnostics and reliable repairs.

- Enhanced Efficiency: With our advanced tools and resources, you can streamline your diagnostic process, reduce downtime, and improve overall efficiency.

Don’t let OBD2 harness issues compromise the performance and reliability of your 2008 Dodge 2500. Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today to learn more about our services and how we can help you resolve your diagnostic challenges.

Contact Information:

- Address: 1100 Congress Ave, Austin, TX 78701, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-DIAGNOSTIC-TOOL.EDU.VN

Take the first step towards resolving your OBD2 harness issues and ensuring the optimal performance of your 2008 Dodge 2500. Reach out to us now and experience the CAR-DIAGNOSTIC-TOOL.EDU.VN difference!