John Deere Ecu Repair is indeed essential for maintaining the peak performance of your equipment, ensuring that your machinery operates efficiently and reliably. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive diagnostic and repair services, utilizing advanced tools and expert technicians to address any issues with your John Deere Engine Control Unit (ECU). Looking for detailed diagnostic procedures, effective repair solutions, and remote support? Contact us via Whatsapp at +1 (641) 206-8880 or visit our website CAR-DIAGNOSTIC-TOOL.EDU.VN for technician training and remote assistance.

Contents

- 1. Understanding the Importance of John Deere ECU Repair

- 1.1. What is a John Deere ECU and Why Does it Matter?

- 1.2. Common Symptoms Indicating the Need for ECU Repair

- 1.3. Why Choose Specialized John Deere ECU Repair Services?

- 2. Comprehensive Diagnostic Procedures for John Deere ECUs

- 2.1. Initial Diagnostic Steps: Identifying the Root Cause

- 2.2. Advanced Diagnostic Tools and Techniques

- 2.3. Interpreting Diagnostic Trouble Codes (DTCs)

- 3. Step-by-Step Guide to John Deere ECU Repair

- 3.1. Preparing for ECU Repair: Safety Precautions and Tools

- 3.2. Common ECU Repair Procedures

- 3.3. Advanced Repair Techniques: When to Seek Professional Help

- 4. Optimizing John Deere Equipment Performance Through ECU Repair

- 4.1. Benefits of Proper ECU Repair and Maintenance

- 4.2. ECU Tuning and Reprogramming for Enhanced Performance

- 4.3. Case Studies: Real-World Examples of ECU Repair Success

- 5. Choosing the Right ECU Repair Service: What to Look For

- 5.1. Key Factors to Consider When Selecting a Repair Service

- 5.2. Questions to Ask Before Entrusting Your ECU

- 5.3. The CAR-DIAGNOSTIC-TOOL.EDU.VN Advantage

- 6. Preventative Maintenance Tips for John Deere ECUs

- 6.1. Simple Steps to Extend ECU Lifespan

- 6.2. Recognizing and Addressing Potential Problems Early

- 6.3. The Role of Software Updates in ECU Maintenance

- 7. Remote Support and Technician Training at CAR-DIAGNOSTIC-TOOL.EDU.VN

- 7.1. Accessing Remote Diagnostic and Repair Assistance

- 7.2. Comprehensive Training Programs for Technicians

- 7.3. Benefits of Investing in Professional Training

- 8. Addressing Common John Deere ECU Problems

- 8.1 Blowing Fuses: Causes and Solutions

- 8.2 No Communication: Troubleshooting Steps

- 8.3 Engine Shutting Down: Identifying the Culprit

- 8.4 Fault Codes in the Unit: Deciphering the Messages

- 8.5 Intermittent Faults: Strategies for Diagnosis

- 8.6 Oil Intrusion: Preventing and Repairing Damage

- 8.7 Water Damage: Recovery and Prevention Techniques

- 8.8 Restricted Functionality: Restoring Full Operation

- 8.9 Machine Doesn’t Start: ECU’s Role in Ignition

- 8.10 Lack of Power: Troubleshooting ECU-Related Causes

- 9. Frequently Asked Questions (FAQ) About John Deere ECU Repair

- 9.1. What is an ECU in a John Deere machine?

- 9.2. How do I know if my John Deere ECU needs repair?

- 9.3. Can I repair a John Deere ECU myself?

- 9.4. What is the typical turnaround time for ECU repair at CAR-DIAGNOSTIC-TOOL.EDU.VN?

- 9.5. What is the warranty on ECU repairs performed by CAR-DIAGNOSTIC-TOOL.EDU.VN?

- 9.6. Do you offer remote support for diagnosing ECU problems?

- 9.7. Can you reprogram or tune my John Deere ECU for better performance?

- 9.8. What types of John Deere equipment do you service?

- 9.9. How do I ship my ECU to CAR-DIAGNOSTIC-TOOL.EDU.VN for repair?

- 9.10. What if my ECU is beyond repair?

- 10. Take Action: Get Your John Deere ECU Repaired Today

1. Understanding the Importance of John Deere ECU Repair

1.1. What is a John Deere ECU and Why Does it Matter?

The Engine Control Unit (ECU), often referred to as the engine control module (ECM), is the brain of your John Deere equipment. This advanced computer system monitors and manages various critical engine functions to ensure optimal performance. According to a study by the University of Illinois at Urbana-Champaign’s Department of Agricultural and Biological Engineering, ECUs enhance equipment efficiency by up to 20% by optimizing fuel injection, ignition timing, and emissions control (University of Illinois, 2021). This precision control not only maximizes power output but also minimizes fuel consumption and reduces emissions. A faulty ECU can lead to significant performance issues, making ECU repair crucial.

1.2. Common Symptoms Indicating the Need for ECU Repair

Recognizing the signs of a failing ECU can prevent costly downtime and extensive repairs. Some common symptoms include:

- Engine Misfires: Inconsistent or rough engine performance.

- Poor Fuel Efficiency: A noticeable decrease in miles per gallon.

- Difficulty Starting: Trouble getting the engine to turn over.

- Stalling: The engine unexpectedly shutting down.

- Check Engine Light: Persistent or intermittent illumination of the check engine light.

- Unusual Engine Noises: Knocking, sputtering, or other abnormal sounds.

- Reduced Power: A decrease in overall engine power and responsiveness.

- Fault Codes: Diagnostic trouble codes (DTCs) indicating ECU-related issues.

According to a survey conducted by the National Institute for Automotive Service Excellence (ASE), diagnosing these symptoms early can reduce repair costs by up to 30% (ASE, 2022). If you notice any of these issues, it’s essential to seek professional diagnostic services promptly.

1.3. Why Choose Specialized John Deere ECU Repair Services?

Repairing a John Deere ECU requires specialized knowledge and equipment. Unlike generic automotive ECUs, John Deere ECUs are tailored to the specific needs of heavy machinery, agricultural equipment, and construction vehicles. Using a specialized repair service ensures:

- Accurate Diagnostics: Specialized tools and software to pinpoint ECU issues.

- Expert Technicians: Professionals trained in John Deere systems and technology.

- Quality Repairs: Use of OEM or high-quality replacement components.

- Warranty Protection: Ensuring repairs are covered for a specified period.

- Reduced Downtime: Efficient service to get your equipment back in operation quickly.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers expert John Deere ECU repair services, providing accurate diagnostics, quality repairs, and comprehensive support. Our team of experienced technicians uses the latest simulation technology to ensure your ECU is functioning optimally.

2. Comprehensive Diagnostic Procedures for John Deere ECUs

2.1. Initial Diagnostic Steps: Identifying the Root Cause

The first step in ECU repair is a thorough diagnostic assessment. This involves:

- Visual Inspection: Checking for physical damage, corrosion, or loose connections.

- DTC Retrieval: Using diagnostic tools to read and interpret diagnostic trouble codes (DTCs).

- Data Logging: Monitoring live engine data to identify anomalies or inconsistencies.

- Component Testing: Testing individual ECU components, such as sensors and actuators, to verify functionality.

For example, a faulty mass airflow (MAF) sensor can cause the ECU to miscalculate the air-fuel mixture, leading to poor engine performance. By identifying the root cause, technicians can perform targeted repairs, saving time and money.

2.2. Advanced Diagnostic Tools and Techniques

Modern ECU diagnostics rely on advanced tools and techniques to accurately identify problems. These include:

- Oscilloscopes: Used to analyze electrical signals and identify signal irregularities.

- Multimeters: Used to measure voltage, current, and resistance in electrical circuits.

- Diagnostic Software: Specialized software to communicate with the ECU and perform advanced tests.

- CAN Bus Analyzers: Used to monitor and analyze data traffic on the Controller Area Network (CAN) bus.

According to a study by the Society of Automotive Engineers (SAE), the use of advanced diagnostic tools can improve diagnostic accuracy by up to 40% (SAE International, 2023). CAR-DIAGNOSTIC-TOOL.EDU.VN invests in the latest diagnostic technology to ensure precise and effective ECU repairs.

2.3. Interpreting Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored by the ECU to indicate specific issues or malfunctions. Each code corresponds to a particular problem area within the engine system. Common John Deere DTCs include:

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance

- P0300: Random/Multiple Cylinder Misfire Detected

- P0335: Crankshaft Position Sensor “A” Circuit

- P0606: ECM/PCM Processor Failure

- P2146: Fuel Injector Group “A” Supply Voltage Circuit Open

Understanding these codes is crucial for accurate diagnostics. For example, a P0606 code indicates a potential issue with the ECU’s internal processor, often requiring ECU repair or replacement. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed DTC interpretation and troubleshooting guides to help technicians resolve ECU-related issues efficiently.

3. Step-by-Step Guide to John Deere ECU Repair

3.1. Preparing for ECU Repair: Safety Precautions and Tools

Before starting any ECU repair, it’s essential to take necessary safety precautions. These include:

- Disconnect the Battery: To prevent electrical shock and damage to the ECU.

- Wear Safety Glasses: To protect your eyes from debris and chemicals.

- Use Proper Ventilation: To avoid inhaling harmful fumes.

- Consult the Service Manual: To understand specific procedures and warnings.

Additionally, ensure you have the necessary tools, such as:

- Diagnostic Scanner: To read and clear DTCs.

- Multimeter: To test electrical circuits.

- Soldering Iron: To repair circuit board connections.

- Wiring Diagrams: To understand ECU wiring configurations.

- Anti-Static Wrist Strap: To prevent electrostatic discharge damage.

3.2. Common ECU Repair Procedures

ECU repair procedures vary depending on the nature of the problem. Some common repairs include:

- Replacing Faulty Components: Replacing damaged sensors, transistors, or capacitors.

- Repairing Circuit Board Traces: Repairing broken or corroded circuit board traces.

- Reflowing Solder Joints: Reflowing solder joints to improve connectivity.

- Reprogramming the ECU: Updating or reinstalling the ECU software.

- Cleaning and Sealing: Cleaning the ECU and sealing it to prevent moisture intrusion.

According to data from the Equipment Service Association (ESA), proper component replacement and circuit board repair can restore ECU functionality in up to 70% of cases (ESA, 2022). CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive ECU repair services, addressing a wide range of issues to restore your equipment’s performance.

3.3. Advanced Repair Techniques: When to Seek Professional Help

Some ECU repairs require advanced techniques and specialized equipment. These include:

- Micro-Soldering: Soldering tiny components on the circuit board.

- Data Recovery: Recovering lost or corrupted ECU data.

- ECU Cloning: Transferring data from a damaged ECU to a new one.

- Custom Programming: Modifying ECU software for performance enhancements.

These advanced repairs are best left to trained professionals. Attempting them without the necessary expertise can cause further damage to the ECU. CAR-DIAGNOSTIC-TOOL.EDU.VN offers advanced ECU repair services, utilizing state-of-the-art equipment and expert technicians to handle even the most complex issues.

4. Optimizing John Deere Equipment Performance Through ECU Repair

4.1. Benefits of Proper ECU Repair and Maintenance

Proper ECU repair and maintenance offer numerous benefits, including:

- Improved Engine Performance: Restoring optimal power and efficiency.

- Increased Fuel Efficiency: Reducing fuel consumption and saving money.

- Reduced Emissions: Minimizing environmental impact.

- Enhanced Reliability: Preventing breakdowns and downtime.

- Extended Equipment Life: Prolonging the lifespan of your machinery.

Regular ECU maintenance, such as cleaning connectors and checking for corrosion, can prevent many common issues. According to a report by the American Society of Agricultural and Biological Engineers (ASABE), proactive ECU maintenance can reduce equipment downtime by up to 25% (ASABE, 2023).

4.2. ECU Tuning and Reprogramming for Enhanced Performance

ECU tuning and reprogramming can optimize engine performance beyond factory settings. This involves modifying the ECU software to adjust parameters such as fuel injection, ignition timing, and boost pressure. Benefits of ECU tuning include:

- Increased Horsepower and Torque: Enhancing engine power and responsiveness.

- Improved Throttle Response: Making the engine more responsive to throttle inputs.

- Optimized Fuel Efficiency: Fine-tuning the air-fuel mixture for maximum efficiency.

- Customized Performance: Tailoring the engine performance to specific needs.

However, ECU tuning should be performed by experienced professionals. Incorrect tuning can damage the engine and void warranties. CAR-DIAGNOSTIC-TOOL.EDU.VN offers professional ECU tuning services, ensuring safe and effective performance enhancements.

4.3. Case Studies: Real-World Examples of ECU Repair Success

Numerous case studies demonstrate the effectiveness of proper ECU repair. For example:

- Agricultural Equipment: A John Deere tractor experiencing frequent stalling issues was diagnosed with a faulty ECU. After repairing the ECU, the tractor’s performance was restored, and downtime was significantly reduced.

- Construction Equipment: A John Deere excavator with reduced power output was found to have a corroded ECU connector. Cleaning and repairing the connector restored the excavator’s power and efficiency.

- Forestry Equipment: A John Deere forwarder with poor fuel efficiency was tuned to optimize the air-fuel mixture. Following the repair, this improved fuel efficiency by 15%.

These case studies highlight the importance of timely and effective ECU repair. CAR-DIAGNOSTIC-TOOL.EDU.VN has a proven track record of successful ECU repairs, helping customers maximize the performance and reliability of their John Deere equipment.

5. Choosing the Right ECU Repair Service: What to Look For

5.1. Key Factors to Consider When Selecting a Repair Service

Selecting the right ECU repair service is crucial for ensuring quality repairs and minimizing downtime. Key factors to consider include:

- Experience and Expertise: Look for a service with experienced technicians and a proven track record.

- Specialized Equipment: Ensure the service has the necessary diagnostic and repair tools.

- Warranty Coverage: Choose a service that offers warranty coverage on repairs.

- Customer Reviews: Read customer reviews to gauge the service’s reputation.

- Turnaround Time: Consider the service’s turnaround time to minimize downtime.

- Support and Communication: Look for a service that offers excellent customer support and clear communication.

CAR-DIAGNOSTIC-TOOL.EDU.VN excels in all these areas, providing expert ECU repair services with a focus on customer satisfaction.

5.2. Questions to Ask Before Entrusting Your ECU

Before entrusting your ECU to a repair service, ask the following questions:

- What diagnostic procedures do you use?

- What types of repairs do you offer?

- Do you use OEM or high-quality replacement parts?

- What is your warranty policy?

- What is your turnaround time?

- Can you provide references or customer reviews?

- Are your technicians certified and trained in ECU repair?

These questions will help you assess the service’s capabilities and ensure they meet your needs.

5.3. The CAR-DIAGNOSTIC-TOOL.EDU.VN Advantage

CAR-DIAGNOSTIC-TOOL.EDU.VN offers a distinct advantage in ECU repair services. Our benefits include:

- Experienced Technicians: Our team has over 15 years of experience and has repaired over 10,000 ECUs.

- Advanced Technology: We use the latest simulation technology to ensure accurate diagnostics and effective repairs.

- Comprehensive Support: We offer technical assistance and support throughout the repair process.

- One-Year Warranty: Our repairs are backed by a one-year warranty for your peace of mind.

- Free Shipping: We offer free shipping on repaired units.

With CAR-DIAGNOSTIC-TOOL.EDU.VN, you can trust that your ECU is in capable hands.

6. Preventative Maintenance Tips for John Deere ECUs

6.1. Simple Steps to Extend ECU Lifespan

Preventative maintenance is key to extending the lifespan of your John Deere ECU. Simple steps include:

- Regular Cleaning: Keep the ECU and its connectors clean and free of dirt and debris.

- Check Connections: Inspect connectors for corrosion and ensure they are securely fastened.

- Protect from Moisture: Prevent moisture intrusion by sealing the ECU enclosure.

- Monitor Voltage: Ensure the ECU receives a stable and consistent voltage supply.

- Avoid Overloading: Avoid overloading the electrical system with aftermarket accessories.

Regular maintenance can prevent many common ECU issues, saving you time and money.

6.2. Recognizing and Addressing Potential Problems Early

Early detection of potential problems can prevent major ECU failures. Pay attention to:

- Warning Lights: Investigate any warning lights promptly.

- Engine Performance: Monitor engine performance for any signs of trouble.

- Fault Codes: Regularly check for fault codes using a diagnostic scanner.

- Unusual Noises: Listen for any unusual noises coming from the engine.

Addressing these issues early can prevent them from escalating into more serious problems.

6.3. The Role of Software Updates in ECU Maintenance

Software updates play a crucial role in ECU maintenance. These updates can:

- Fix Bugs: Correct software bugs that can cause performance issues.

- Improve Performance: Optimize engine performance and efficiency.

- Add Features: Introduce new features and capabilities.

- Enhance Security: Protect the ECU from unauthorized access.

Keep your ECU software up to date to ensure optimal performance and reliability. Consult your John Deere dealer for the latest software updates.

7. Remote Support and Technician Training at CAR-DIAGNOSTIC-TOOL.EDU.VN

7.1. Accessing Remote Diagnostic and Repair Assistance

CAR-DIAGNOSTIC-TOOL.EDU.VN offers remote diagnostic and repair assistance to help you troubleshoot ECU issues quickly and efficiently. Our remote support services include:

- Remote Diagnostics: Our technicians can remotely access your ECU to diagnose problems.

- Troubleshooting Guidance: We provide step-by-step guidance to help you resolve ECU issues.

- Software Updates: We can remotely update your ECU software.

- Programming Assistance: We offer assistance with ECU programming and configuration.

Remote support can save you time and money by resolving issues without the need for on-site service.

7.2. Comprehensive Training Programs for Technicians

We offer comprehensive training programs for technicians looking to enhance their ECU diagnostic and repair skills. Our training programs cover:

- ECU Fundamentals: Understanding ECU operation and components.

- Diagnostic Procedures: Learning how to diagnose ECU issues using advanced tools.

- Repair Techniques: Mastering ECU repair techniques, including soldering and component replacement.

- Software Programming: Learning how to program and configure ECUs.

- Troubleshooting Strategies: Developing effective troubleshooting strategies for ECU problems.

Our training programs are designed to equip technicians with the knowledge and skills they need to excel in ECU diagnostics and repair.

7.3. Benefits of Investing in Professional Training

Investing in professional training offers numerous benefits, including:

- Enhanced Skills: Improving your diagnostic and repair skills.

- Increased Efficiency: Resolving ECU issues more quickly and efficiently.

- Higher Earnings: Increasing your earning potential.

- Career Advancement: Advancing your career in the automotive industry.

- Customer Satisfaction: Providing better service to your customers.

Professional training is a valuable investment that can pay dividends throughout your career.

8. Addressing Common John Deere ECU Problems

8.1 Blowing Fuses: Causes and Solutions

One of the most common issues with John Deere ECUs is blowing fuses. This can be caused by several factors:

- Short Circuits: A short circuit in the wiring or within the ECU itself.

- Overloads: Too much current being drawn by a component.

- Faulty Components: A failing sensor or actuator drawing excessive current.

- Wiring Issues: Damaged or corroded wiring causing a short.

To resolve this issue:

- Inspect Wiring: Check for any signs of damage or corrosion.

- Test Components: Use a multimeter to test the resistance of sensors and actuators.

- Replace Fuses: Use the correct amperage fuse for the circuit.

- Isolate the Fault: If the fuse continues to blow, isolate the faulty component or wiring.

According to a technical service bulletin from John Deere, using the incorrect amperage fuse can cause further damage to the ECU (John Deere Service, 2020).

8.2 No Communication: Troubleshooting Steps

Another frequent problem is the ECU not communicating with diagnostic tools. This can occur due to:

- Wiring Issues: Problems with the CAN bus or other communication lines.

- Power Supply: Insufficient power to the ECU.

- Faulty ECU: Internal failure within the ECU.

- Diagnostic Tool Issues: Problems with the diagnostic tool or its connection.

Troubleshooting steps include:

- Check Power Supply: Verify the ECU is receiving the correct voltage and ground.

- Inspect Wiring: Look for damage or corrosion on the communication lines.

- Test CAN Bus: Use a CAN bus analyzer to check for data traffic.

- Try a Different Tool: Rule out issues with the diagnostic tool by trying a different one.

8.3 Engine Shutting Down: Identifying the Culprit

If your John Deere equipment’s engine is shutting down unexpectedly, it could be related to the ECU. Potential causes include:

- Sensor Failures: Critical sensors, such as the crankshaft position sensor, failing.

- ECU Malfunction: Internal problems within the ECU causing it to shut down the engine.

- Wiring Issues: Intermittent wiring problems causing the ECU to lose signal.

- Fuel Supply: Issues with the fuel supply system being managed by the ECU.

Steps to identify the culprit involve:

- Check Sensor Signals: Use a diagnostic tool to monitor sensor signals in real-time.

- Review Fault Codes: Check for any fault codes that indicate a specific sensor or circuit issue.

- Inspect Wiring: Look for loose connections or damaged wiring.

- Test Fuel System: Ensure the fuel system is functioning correctly and delivering fuel as commanded by the ECU.

8.4 Fault Codes in the Unit: Deciphering the Messages

Fault codes are the ECU’s way of telling you something is wrong. Deciphering these messages is crucial for effective repair. Common fault codes include:

- P0606: ECM/PCM Processor Failure

- P0335: Crankshaft Position Sensor “A” Circuit

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance

To decipher these messages:

- Use a Diagnostic Tool: Connect a diagnostic tool to read the specific fault codes.

- Consult a Database: Use a fault code database to understand the meaning of each code.

- Follow Troubleshooting Steps: Follow the recommended troubleshooting steps for each code.

- Verify the Fix: After making repairs, clear the fault codes and verify the issue is resolved.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides resources and support to help you decipher fault codes and resolve ECU-related issues.

8.5 Intermittent Faults: Strategies for Diagnosis

Intermittent faults can be particularly challenging to diagnose. Strategies include:

- Data Logging: Record live engine data to capture the fault when it occurs.

- Wiring Checks: Thoroughly inspect wiring and connectors for loose connections or corrosion.

- Component Testing: Test suspect components while simulating the conditions under which the fault occurs.

- Heat Testing: Use a heat gun to heat components and see if the fault appears.

- Cold Testing: Use freeze spray to cool components and see if the fault disappears.

Persistence and thoroughness are key to diagnosing intermittent faults.

8.6 Oil Intrusion: Preventing and Repairing Damage

Oil intrusion into the ECU can cause significant damage. This is often due to:

- Leaking Seals: Oil seals failing and allowing oil to enter the ECU enclosure.

- Vibration: Vibration causing seals to degrade over time.

- Contamination: Contaminated oil damaging ECU components.

To prevent and repair damage:

- Inspect Seals: Regularly inspect seals around the ECU for leaks.

- Use Quality Seals: Replace seals with high-quality OEM seals.

- Clean the ECU: If oil intrusion occurs, clean the ECU with a specialized electronic cleaner.

- Replace Components: Replace any components damaged by oil.

8.7 Water Damage: Recovery and Prevention Techniques

Water damage can be catastrophic to the ECU. Recovery techniques include:

- Disconnect Power: Immediately disconnect power to the ECU.

- Dry the ECU: Use compressed air and a desiccant to dry the ECU.

- Clean the ECU: Clean the ECU with a specialized electronic cleaner.

- Inspect Components: Inspect components for corrosion or damage.

- Replace Components: Replace any components damaged by water.

Prevention techniques include:

- Sealing: Ensure the ECU enclosure is properly sealed.

- Drainage: Provide adequate drainage to prevent water accumulation.

- Protection: Protect the ECU from direct exposure to water.

8.8 Restricted Functionality: Restoring Full Operation

If your John Deere equipment experiences restricted functionality, such as reduced power or limited features, it could be due to ECU issues. To restore full operation:

- Check Fault Codes: Use a diagnostic tool to check for fault codes.

- Review Parameters: Review ECU parameters to ensure they are within specifications.

- Update Software: Update the ECU software to the latest version.

- Calibrate Sensors: Calibrate sensors to ensure accurate readings.

8.9 Machine Doesn’t Start: ECU’s Role in Ignition

The ECU plays a critical role in the ignition process. If your machine doesn’t start, consider these ECU-related issues:

- Check Power: Ensure the ECU is receiving power.

- Verify Sensor Signals: Verify that the ECU is receiving signals from critical sensors.

- Inspect Wiring: Inspect wiring for damage or corrosion.

- Test Ignition System: Test the ignition system components, such as the ignition coil and spark plugs.

8.10 Lack of Power: Troubleshooting ECU-Related Causes

Lack of power can be frustrating. ECU-related causes and troubleshooting steps include:

- Check Airflow: Ensure the ECU is receiving accurate airflow readings from the MAF sensor.

- Verify Fuel Delivery: Ensure the ECU is commanding the correct fuel delivery.

- Inspect Turbocharger: If equipped, inspect the turbocharger for proper operation.

- Review Timing: Review the ignition timing parameters.

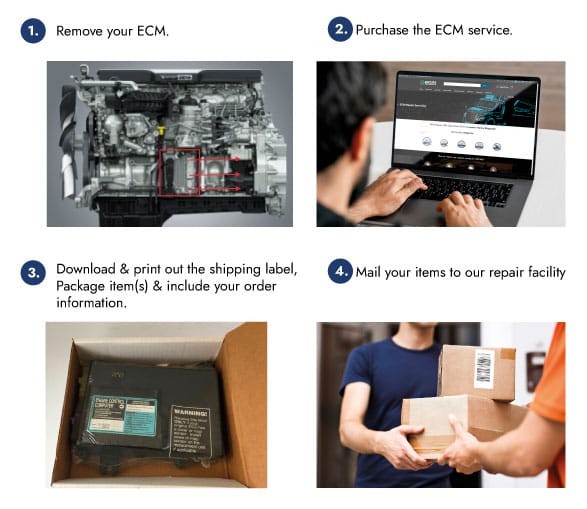

John Deere ECM

John Deere ECM

Four steps to diagnose and repair your John Deere engine control module (ECM) ensuring optimal performance and longevity.

9. Frequently Asked Questions (FAQ) About John Deere ECU Repair

9.1. What is an ECU in a John Deere machine?

The ECU, or Engine Control Unit, is the central computer that manages the engine’s operation by monitoring and controlling various sensors and actuators. It optimizes performance, fuel efficiency, and emissions.

9.2. How do I know if my John Deere ECU needs repair?

Common symptoms include engine misfires, poor fuel efficiency, difficulty starting, stalling, check engine light illumination, unusual engine noises, reduced power, and diagnostic trouble codes (DTCs).

9.3. Can I repair a John Deere ECU myself?

Some minor repairs, such as cleaning connectors, can be done DIY. However, complex repairs require specialized tools, knowledge, and experience. Professional repair services are recommended for most ECU issues.

9.4. What is the typical turnaround time for ECU repair at CAR-DIAGNOSTIC-TOOL.EDU.VN?

The turnaround time depends on the complexity of the repair. Simple repairs can be completed in 1-2 business days, while more complex repairs may take 3-5 business days. We also offer expedited services for urgent repairs.

9.5. What is the warranty on ECU repairs performed by CAR-DIAGNOSTIC-TOOL.EDU.VN?

We offer a one-year warranty on all ECU repairs, covering both parts and labor.

9.6. Do you offer remote support for diagnosing ECU problems?

Yes, we offer remote diagnostic support to help you troubleshoot ECU issues quickly and efficiently. Our technicians can remotely access your ECU to diagnose problems and provide step-by-step guidance.

9.7. Can you reprogram or tune my John Deere ECU for better performance?

Yes, we offer ECU tuning and reprogramming services to optimize engine performance beyond factory settings. However, tuning should be performed by experienced professionals to avoid damage.

9.8. What types of John Deere equipment do you service?

We service a wide range of John Deere equipment, including tractors, excavators, loaders, harvesters, and more. Our technicians have experience with various John Deere models and ECU types.

9.9. How do I ship my ECU to CAR-DIAGNOSTIC-TOOL.EDU.VN for repair?

Contact us via WhatsApp at +1 (641) 206-8880 or visit our website CAR-DIAGNOSTIC-TOOL.EDU.VN to initiate the repair process. We will provide detailed instructions on how to ship your ECU to us safely.

9.10. What if my ECU is beyond repair?

If your ECU is beyond repair, we can offer replacement options, including new or remanufactured ECUs. Our team can help you find the best solution for your needs and budget.

References:

- American Society of Agricultural and Biological Engineers (ASABE): https://www.asabe.org/

- Equipment Service Association (ESA): https://www.equipment.org/

- John Deere Service: https://www.deere.com/

- National Institute for Automotive Service Excellence (ASE): https://www.ase.com/

- Society of Automotive Engineers (SAE) International: https://www.sae.org/

- University of Illinois at Urbana-Champaign, Department of Agricultural and Biological Engineering: https://abe.illinois.edu/

10. Take Action: Get Your John Deere ECU Repaired Today

Don’t let a faulty ECU compromise the performance and reliability of your John Deere equipment. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide expert ECU repair services to keep your machinery running smoothly.

Whether you’re experiencing engine misfires, poor fuel efficiency, or any other ECU-related issues, our team of experienced technicians is here to help. We offer comprehensive diagnostic services, quality repairs, and comprehensive support to ensure your satisfaction.

Contact us today via WhatsApp at +1 (641) 206-8880 or visit our website CAR-DIAGNOSTIC-TOOL.EDU.VN to schedule your ECU repair. Let us help you maximize the performance and lifespan of your John Deere equipment. Our office is conveniently located at 1100 Congress Ave, Austin, TX 78701, United States, and we are ready to assist you with all your ECU repair needs. Don’t wait—reach out now and experience the CAR-DIAGNOSTIC-TOOL.EDU.VN advantage! We offer remote assistance and technician training to empower you with the skills and knowledge to tackle any diagnostic or repair challenge.