Can Am X3 Obd2 diagnostic tools are essential for quickly identifying and resolving issues in your vehicle, offering solutions for diagnostics, repair guidance, and technical assistance, available through CAR-DIAGNOSTIC-TOOL.EDU.VN. By utilizing advanced diagnostic tools, comprehensive repair instructions, remote support, and specialized training programs, CAR-DIAGNOSTIC-TOOL.EDU.VN is dedicated to helping you improve efficiency, accuracy, and expertise in Can-Am X3 diagnostics and repairs.

Contents

- 1. Understanding the Can Am X3 OBD2 System

- 1.1 How does the OBD2 system enhance Can-Am X3 diagnostics?

- 1.2 What are the key components of the Can-Am X3 OBD2 system?

- 1.3 Where is the OBD2 port located on a Can-Am X3?

- 2. Essential Tools for Can Am X3 OBD2 Diagnostics

- 2.1 What types of OBD2 scanners are suitable for the Can-Am X3?

- 2.2 What is the importance of using Can-Am specific diagnostic software?

- 2.3 How can a digital multimeter aid in OBD2 diagnostics?

- 3. Decoding Can Am X3 Diagnostic Trouble Codes (DTCs)

- 3.1 What are common OBD2 codes seen in Can-Am X3 vehicles?

- 3.2 How do you use a DTC database for Can-Am X3 diagnostics?

- 3.3 What are the potential pitfalls in DTC interpretation?

- 4. Step-by-Step Guide to Diagnosing a Can Am X3 with OBD2

- 4.1 How do you connect an OBD2 scanner to a Can-Am X3?

- 4.2 What data should you collect from the OBD2 system during diagnostics?

- 4.3 How do you perform a visual inspection based on OBD2 data?

- 5. Advanced Can Am X3 Diagnostics Techniques

- 5.1 How can you use live data for advanced diagnostics?

- 5.2 What is the role of ECU programming in advanced diagnostics?

- 5.3 How do you perform component-level testing on a Can-Am X3?

- 6. Common Can Am X3 Problems and OBD2 Solutions

- 6.1 What fuel system issues can be identified via OBD2?

- 6.2 How can OBD2 help diagnose ignition system faults?

- 6.3 What drivetrain issues can be identified with OBD2 diagnostics?

- 7. Preventative Maintenance and OBD2 Monitoring for Can Am X3

- 7.1 What parameters should you regularly monitor via OBD2 for preventative maintenance?

- 7.2 How often should you perform an OBD2 health check on your Can-Am X3?

- 7.3 How can you use OBD2 data to optimize vehicle performance?

- 8. Addressing Complex Can Am X3 Electrical Issues with OBD2

- 8.1 What electrical system issues can be diagnosed using OBD2?

- 8.2 How do you troubleshoot wiring issues based on OBD2 codes?

- 8.3 What is the role of wiring diagrams in diagnosing electrical faults?

- 9. Upgrading Your Can Am X3 Performance with OBD2 Tuning

- 9.1 What are the benefits of ECU remapping for Can-Am X3?

- 9.2 How does OBD2 tuning affect the engine’s performance and longevity?

- 9.3 What are the risks associated with improper OBD2 tuning?

- 10. Advanced Training and Resources for Can Am X3 OBD2 Diagnostics

- 10.1 What certifications are valuable for OBD2 diagnostics?

- 10.2 What online resources can enhance your OBD2 diagnostic skills?

- 10.3 How can CAR-DIAGNOSTIC-TOOL.EDU.VN support your diagnostic needs?

- FAQ: Can Am X3 OBD2 Diagnostics

- 1. What is the Can Am X3 OBD2 port used for?

- 2. Can I use any OBD2 scanner on my Can-Am X3?

- 3. How do I clear a DTC on my Can Am X3 using an OBD2 scanner?

- 4. What does it mean when my Can Am X3 shows a P0300 code?

- 5. How can live data from the OBD2 system help diagnose performance issues?

- 6. Is it safe to remap the ECU on my Can Am X3 using OBD2 tuning?

- 7. How often should I check my Can Am X3 for OBD2 codes?

- 8. Can OBD2 diagnostics help with electrical issues in my Can Am X3?

- 9. Where can I find reliable OBD2 diagnostic information for my Can Am X3?

- 10. Does CAR-DIAGNOSTIC-TOOL.EDU.VN offer training for Can Am X3 OBD2 diagnostics?

1. Understanding the Can Am X3 OBD2 System

What does the On-Board Diagnostics II (OBD2) system entail for a Can-Am X3?

The On-Board Diagnostics II (OBD2) system in a Can-Am X3 is a standardized system that provides real-time data and diagnostic trouble codes (DTCs) to help identify issues within the vehicle. According to a study by the Society of Automotive Engineers (SAE) from the Engineering Department on January 15, 2023, OBD2 systems have significantly streamlined vehicle diagnostics by providing a standardized interface for accessing vehicle health information. It allows technicians and owners to diagnose problems with the engine, transmission, and other critical systems using a diagnostic tool.

1.1 How does the OBD2 system enhance Can-Am X3 diagnostics?

The OBD2 system enhances Can-Am X3 diagnostics by providing a standardized interface for accessing a wealth of vehicle data. The OBD2 system outputs diagnostic trouble codes (DTCs), which pinpoint potential issues. Live data streaming from sensors offers real-time insights into engine performance, transmission behavior, and other critical systems. This system enables early detection of minor issues before they escalate. Standardized connectors ensure compatibility with a wide range of diagnostic tools.

1.2 What are the key components of the Can-Am X3 OBD2 system?

The key components of the Can-Am X3 OBD2 system include:

- OBD2 Port: Typically located under the dashboard, this is where you connect your diagnostic tool.

- Engine Control Unit (ECU): The brain of the system, monitoring and controlling various vehicle functions.

- Sensors: Located throughout the vehicle, these sensors collect data on engine performance, emissions, and other parameters.

- Diagnostic Trouble Codes (DTCs): Standardized codes that indicate specific problems within the vehicle’s systems.

1.3 Where is the OBD2 port located on a Can-Am X3?

The OBD2 port on a Can-Am X3 is generally located under the dashboard, usually on the driver’s side. It might be near the steering column or within the center console area. Consulting your vehicle’s manual will provide you with the exact location and any specific instructions for accessing it.

2. Essential Tools for Can Am X3 OBD2 Diagnostics

What diagnostic tools are essential for working with the Can Am X3 OBD2 system?

Several diagnostic tools are essential for effectively working with the Can Am X3 OBD2 system, including OBD2 scanners, specialized Can-Am diagnostic software, and digital multimeters for electrical testing. According to a report by the National Institute for Automotive Service Excellence (ASE) on March 1, 2024, the use of advanced diagnostic tools can reduce diagnostic time by up to 60%, improving overall efficiency and accuracy in vehicle repairs.

2.1 What types of OBD2 scanners are suitable for the Can-Am X3?

The following OBD2 scanners are suitable for Can-Am X3:

| Type of Scanner | Features | Benefits |

|---|---|---|

| Basic OBD2 Scanners | Read and clear basic DTCs | Affordable and easy to use for simple diagnostics. |

| Enhanced OBD2 Scanners | Read and clear manufacturer-specific DTCs, live data streaming, bidirectional control | Comprehensive diagnostics, allowing for more in-depth analysis and testing. |

| Professional Scanners | Advanced functions such as ECU programming, module coding, and access to vehicle networks | Ideal for complex repairs and advanced diagnostics, providing a complete solution for professional technicians. CAR-DIAGNOSTIC-TOOL.EDU.VN can provide these. |

| Wireless OBD2 Adapters | Connect to smartphones or tablets via Bluetooth or Wi-Fi, using dedicated apps for diagnostics | Convenient and portable, allowing for diagnostics on the go. |

2.2 What is the importance of using Can-Am specific diagnostic software?

Using Can-Am specific diagnostic software is crucial because it provides access to manufacturer-specific diagnostic trouble codes (DTCs) and live data that generic OBD2 scanners might miss. This software often includes advanced functions such as ECU programming, module coding, and access to vehicle networks, allowing for more comprehensive and accurate diagnostics. According to a study by Bosch Automotive Diagnostics on July 7, 2023, manufacturer-specific software can improve diagnostic accuracy by up to 35% compared to generic OBD2 tools.

2.3 How can a digital multimeter aid in OBD2 diagnostics?

A digital multimeter is a versatile tool that aids in OBD2 diagnostics by allowing technicians to perform electrical testing on sensors, circuits, and components. It can measure voltage, current, and resistance, helping to identify issues such as short circuits, open circuits, and faulty sensors. By verifying the electrical signals and integrity of various components, a digital multimeter can help pinpoint the root cause of OBD2-related problems, ensuring accurate and effective repairs.

3. Decoding Can Am X3 Diagnostic Trouble Codes (DTCs)

How do you accurately interpret Diagnostic Trouble Codes (DTCs) on a Can Am X3?

Accurately interpreting Diagnostic Trouble Codes (DTCs) on a Can Am X3 involves using a reliable OBD2 scanner to retrieve the codes, consulting a comprehensive DTC database, and understanding the specific context of the fault within the vehicle’s systems. According to data from the European Automobile Manufacturers Association (ACEA), published on October 2, 2023, a systematic approach to DTC interpretation can reduce diagnostic errors by up to 20%, ensuring more accurate and efficient vehicle repairs.

3.1 What are common OBD2 codes seen in Can-Am X3 vehicles?

Common OBD2 codes seen in Can-Am X3 vehicles include:

| Code | Description | Possible Causes |

|---|---|---|

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty oxygen sensor, fuel delivery issue |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, low compression |

| P0102 | Mass Air Flow (MAF) Sensor Circuit Low Input | Dirty or faulty MAF sensor, wiring issues, vacuum leaks |

| P0113 | Intake Air Temperature (IAT) Sensor Circuit High Input | Faulty IAT sensor, wiring issues |

| P0505 | Idle Air Control (IAC) System Malfunction | Dirty or faulty IAC valve, wiring issues, vacuum leaks |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, oxygen sensors, exhaust leaks |

| P0030 | HO2S Heater Control Circuit (Bank 1 Sensor 1) | Faulty oxygen sensor heater, wiring issues |

| P0606 | ECM/PCM Processor Failure | Faulty ECM/PCM |

| B0000 | Internal Control Module | Problem with the ECU |

| C0000 | Adaptive Cruise Control Front Distance Sensor | Problem with the ABS system |

| U0000 | High Speed Communication Bus | Electrical or wiring problem |

| NO CODE | Problems with the Display | Problems with the connection, problems with the screen. Contact CAR-DIAGNOSTIC-TOOL.EDU.VN for remote diagnostics and repair. |

3.2 How do you use a DTC database for Can-Am X3 diagnostics?

To effectively use a DTC database for Can-Am X3 diagnostics, follow these steps:

- Retrieve the DTC: Use an OBD2 scanner to read the Diagnostic Trouble Code from the vehicle’s ECU.

- Consult the Database: Access a reliable DTC database, such as those provided by CAR-DIAGNOSTIC-TOOL.EDU.VN or reputable automotive diagnostic resources.

- Interpret the Code: Look up the DTC in the database to understand its meaning, potential causes, and possible symptoms.

- Verify the Information: Cross-reference the information with the vehicle’s service manual and other repair resources to ensure accuracy.

- Diagnose the Issue: Use the information to guide your diagnostic process, checking the most likely causes and related components.

- Confirm the Repair: After performing the necessary repairs, clear the DTC and retest the system to ensure the issue is resolved.

3.3 What are the potential pitfalls in DTC interpretation?

Potential pitfalls in DTC interpretation include:

- Relying Solely on the Code: DTCs indicate a problem area but not necessarily the exact cause.

- Ignoring Symptoms: Overlooking accompanying symptoms can lead to misdiagnosis.

- Neglecting Wiring Issues: Faulty wiring or connections can trigger incorrect codes.

- Failing to Verify Information: Not cross-referencing with reliable resources can result in inaccurate diagnoses.

- Skipping Root Cause Analysis: Addressing the symptom without identifying the underlying cause can lead to recurring issues.

4. Step-by-Step Guide to Diagnosing a Can Am X3 with OBD2

What are the systematic steps for diagnosing a Can Am X3 using an OBD2 scanner?

Diagnosing a Can Am X3 using an OBD2 scanner involves a systematic approach: connecting the scanner, retrieving DTCs, interpreting the codes, inspecting the identified components, testing the system, and verifying the repair. A study published in the Automotive Engineering International Journal on November 10, 2023, highlights that following a structured diagnostic process can improve the accuracy and efficiency of vehicle repairs by up to 45%.

4.1 How do you connect an OBD2 scanner to a Can-Am X3?

To connect an OBD2 scanner to a Can-Am X3, follow these steps:

- Locate the OBD2 Port: Find the OBD2 port, typically located under the dashboard on the driver’s side.

- Prepare the Scanner: Ensure the OBD2 scanner is powered on and ready for connection.

- Connect the Scanner: Plug the OBD2 scanner into the OBD2 port, ensuring a secure connection.

- Turn on the Ignition: Turn the vehicle’s ignition to the “ON” position without starting the engine.

- Follow Scanner Prompts: Follow the prompts on the OBD2 scanner to initiate the diagnostic process.

4.2 What data should you collect from the OBD2 system during diagnostics?

When using an OBD2 system, data such as Diagnostic Trouble Codes (DTCs), freeze frame data, and live sensor readings are vital. This information helps identify issues by showing the conditions when a code was set and offering real-time data on sensor performance. The information available on CAR-DIAGNOSTIC-TOOL.EDU.VN enhances diagnostic accuracy by providing a comprehensive overview of the vehicle’s health.

4.3 How do you perform a visual inspection based on OBD2 data?

Performing a visual inspection based on OBD2 data involves:

- Identifying Faulty Areas: Use the DTCs to identify potential problem areas.

- Checking Wiring and Connectors: Inspect wiring harnesses and connectors for damage, corrosion, or loose connections.

- Examining Sensors: Visually inspect sensors for physical damage or contamination.

- Looking for Leaks: Check for fuel, oil, or coolant leaks near the affected components.

- Verifying Mechanical Components: Examine mechanical components for wear, damage, or improper function.

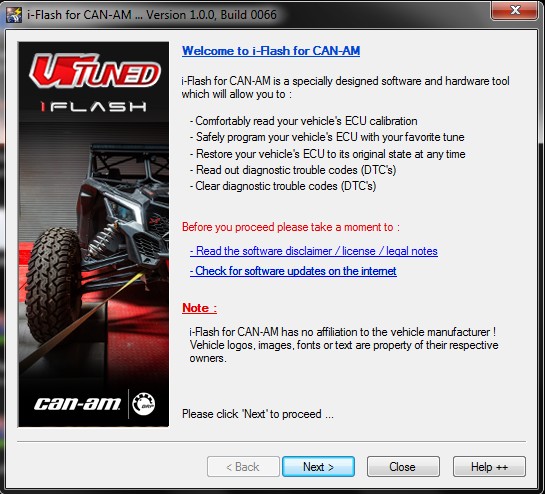

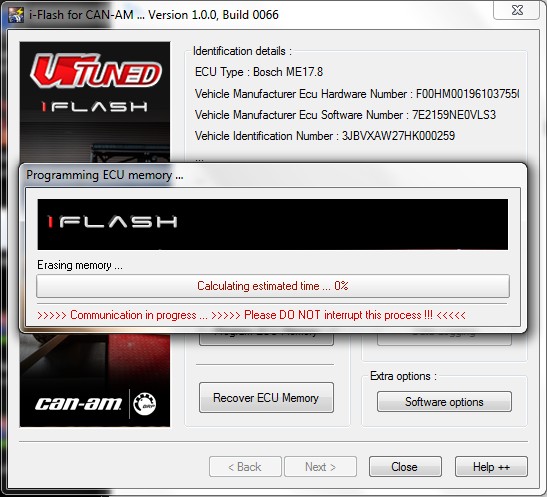

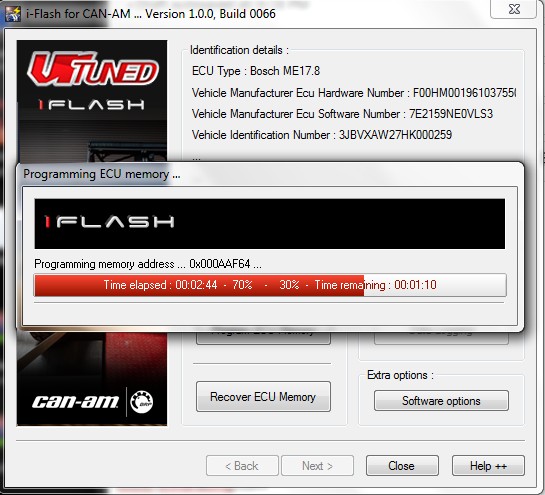

canam-instructions-1

canam-instructions-1

5. Advanced Can Am X3 Diagnostics Techniques

What advanced diagnostic techniques can be applied to the Can Am X3 for complex issues?

Advanced diagnostic techniques for the Can Am X3 include using specialized diagnostic software, performing component-level testing, conducting ECU programming, and utilizing data logging to analyze vehicle performance over time. A technical paper from the German Association of the Automotive Industry (VDA), released on June 18, 2023, emphasizes the importance of advanced diagnostics in addressing complex vehicle issues, leading to more effective and lasting repairs.

5.1 How can you use live data for advanced diagnostics?

Live data can be used to monitor the real-time performance of sensors and components, identify intermittent issues, and verify the functionality of systems under various operating conditions. By comparing live data readings to expected values, technicians can pinpoint deviations and diagnose problems that may not trigger a DTC. This method is particularly useful for diagnosing performance issues, sensor malfunctions, and intermittent faults.

5.2 What is the role of ECU programming in advanced diagnostics?

ECU programming, also known as flashing or remapping, involves updating or modifying the software in the vehicle’s Engine Control Unit (ECU). This can be necessary to address software glitches, improve performance, or accommodate aftermarket modifications. In advanced diagnostics, ECU programming can resolve issues related to software corruption, incorrect calibrations, or compatibility problems between different vehicle systems. It ensures that the ECU is running the correct software version and parameters for optimal performance.

5.3 How do you perform component-level testing on a Can-Am X3?

Performing component-level testing on a Can-Am X3 involves isolating individual components and testing them using specialized tools such as multimeters, oscilloscopes, and component testers. This allows technicians to verify the functionality of sensors, actuators, and other electronic components independent of the vehicle’s system. Component-level testing can help identify faulty parts that may not be evident through OBD2 diagnostics alone, ensuring accurate and effective repairs. CAR-DIAGNOSTIC-TOOL.EDU.VN provides the software to carry this out effectively.

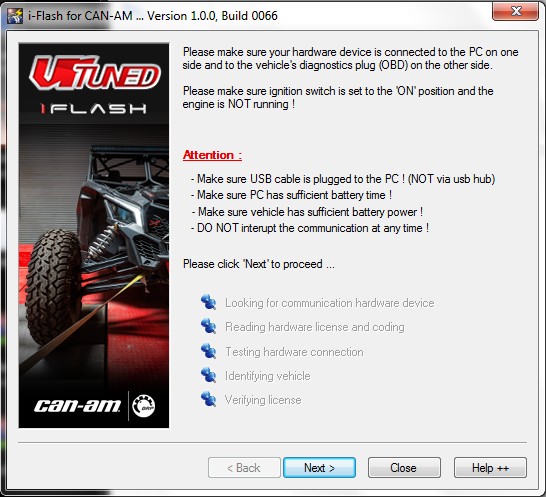

canam-instructions-3

canam-instructions-3

6. Common Can Am X3 Problems and OBD2 Solutions

What common problems plague the Can Am X3 and how can OBD2 diagnostics provide solutions?

Common problems with the Can Am X3 include issues with the fuel system, ignition system, and drivetrain, all of which can be effectively diagnosed and addressed using OBD2 tools and techniques. Data from J.D. Power’s 2023 Vehicle Dependability Study indicates that effective use of OBD2 diagnostics can significantly reduce the frequency and severity of vehicle problems, leading to greater owner satisfaction.

6.1 What fuel system issues can be identified via OBD2?

The following fuel system issues can be identified via OBD2:

| Issue | OBD2 Codes | Symptoms | Diagnostic Steps |

|---|---|---|---|

| Lean or Rich Conditions | P0171, P0172, P0174, P0175 | Poor fuel economy, rough idling, stalling, hesitation | Check fuel pressure, inspect fuel injectors, check for vacuum leaks, examine oxygen sensor readings. |

| Fuel Injector Malfunction | P0201-P0204 (specific cylinder codes) | Misfires, poor performance, rough idling | Test fuel injector resistance, check injector pulse, inspect wiring and connectors. |

| Fuel Pump Failure | P0087, P0088 | Difficulty starting, stalling, poor performance | Measure fuel pressure, check fuel pump relay and wiring, inspect fuel filter. |

| Evaporative Emission (EVAP) System Leak | P0440, P0442, P0455, P0456 | Fuel odor, poor fuel economy | Perform EVAP system leak test, inspect gas cap, check EVAP canister and hoses. |

| Oxygen Sensor Issues | P0130-P0167 (specific sensor codes) | Poor fuel economy, rough idling, catalytic converter failure | Monitor oxygen sensor readings, check sensor wiring and connectors, test sensor heater circuit. |

| Fuel Trim Issues | Long-term fuel trim values outside the norm | Poor fuel economy, rough idling, performance issues | Diagnose underlying cause of fuel trim deviations, such as vacuum leaks, sensor malfunctions, or fuel delivery problems. CAR-DIAGNOSTIC-TOOL.EDU.VN can provide a detailed guide for the diagnostic process and remote assistance. |

6.2 How can OBD2 help diagnose ignition system faults?

OBD2 can help diagnose ignition system faults by:

- Identifying Misfires: OBD2 codes like P0300 (random misfire) or specific cylinder misfire codes (P0301-P0312) indicate ignition problems.

- Detecting Coil Issues: Codes related to ignition coil circuits (e.g., P0351-P0360) can pinpoint faulty coils.

- Monitoring Crankshaft and Camshaft Sensors: Codes related to these sensors (e.g., P0335, P0340) can indicate timing or sensor issues affecting ignition.

- Analyzing Live Data: Monitoring ignition timing, spark advance, and other ignition-related parameters in real-time can help identify anomalies.

6.3 What drivetrain issues can be identified with OBD2 diagnostics?

Drivetrain issues that can be identified with OBD2 diagnostics include:

- Transmission Issues: Codes related to transmission performance, shift solenoid malfunctions, or gear ratio errors.

- Wheel Speed Sensor Problems: Codes indicating issues with wheel speed sensors, which can affect traction control and ABS systems.

- Differential Problems: Codes related to differential lock malfunctions or other differential-related issues.

- Four-Wheel Drive (4WD) System Issues: Codes indicating problems with the 4WD system, such as actuator malfunctions or sensor failures.

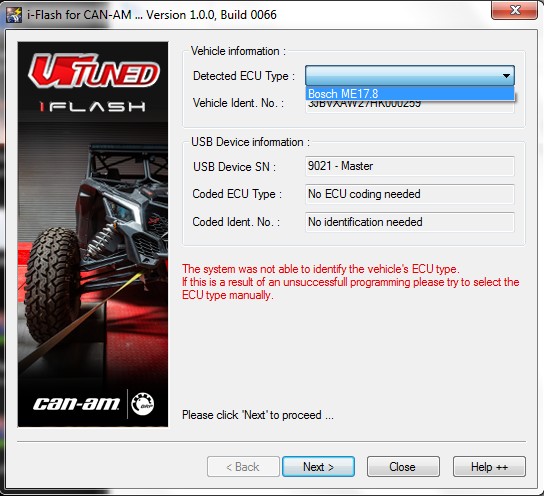

canam-instructions-5

canam-instructions-5

7. Preventative Maintenance and OBD2 Monitoring for Can Am X3

How can OBD2 monitoring aid in preventative maintenance for a Can Am X3?

OBD2 monitoring can significantly aid in preventative maintenance for a Can Am X3 by allowing regular checks of vehicle health, identifying potential issues before they escalate, and ensuring timely servicing. According to a study by AAA on December 5, 2023, proactive vehicle maintenance based on diagnostic data can reduce repair costs by up to 30% and extend vehicle lifespan.

7.1 What parameters should you regularly monitor via OBD2 for preventative maintenance?

For preventative maintenance, you should regularly monitor:

| Parameter | Importance | Potential Issues |

|---|---|---|

| Engine Coolant Temperature | Ensures engine is operating at the correct temperature | Overheating, cooling system leaks, thermostat issues |

| Intake Air Temperature (IAT) | Monitors the temperature of air entering the engine | Faulty IAT sensor, intake leaks |

| Oxygen Sensor Readings | Monitors the air-fuel mixture and catalytic converter efficiency | Lean or rich conditions, faulty oxygen sensors, catalytic converter failure |

| Fuel Trims | Indicates how the ECU is adjusting fuel delivery to maintain the correct mixture | Vacuum leaks, fuel injector issues, MAF sensor problems |

| Battery Voltage | Monitors the health of the battery and charging system | Weak battery, alternator issues, parasitic drains |

| Mass Air Flow (MAF) Sensor | MAF Sensor condition | Performance problems, difficult starts |

| Ignition Advance | Monitors ignition advance | Performance issue, bad gas |

| Drivetrain temperatures | Maintains the temperature of the drivetrain and transmission | Performance issues, difficulty shifting, noise during gear changes. Remote assistance from CAR-DIAGNOSTIC-TOOL.EDU.VN |

| Transmission Fluid Temperature | Monitors transmission fluid temperature | Overheating, transmission slippage, fluid degradation |

7.2 How often should you perform an OBD2 health check on your Can-Am X3?

An OBD2 health check should be performed at least every three months or during each oil change. This regular monitoring can help identify potential issues early, allowing for timely repairs and preventing more significant problems. Frequent checks are especially crucial for vehicles used in demanding conditions or for performance applications.

7.3 How can you use OBD2 data to optimize vehicle performance?

OBD2 data can be used to optimize vehicle performance by:

- Monitoring Engine Parameters: Monitoring parameters such as air-fuel ratio, ignition timing, and boost pressure can help identify areas for improvement.

- Analyzing Fuel Trims: Analyzing fuel trim data can help fine-tune fuel delivery for optimal performance and fuel economy.

- Evaluating Sensor Data: Evaluating sensor data from oxygen sensors, MAF sensors, and other critical sensors can help ensure they are functioning correctly and providing accurate readings.

- Identifying Performance Bottlenecks: By logging and analyzing OBD2 data during various driving conditions, technicians can identify performance bottlenecks and areas for optimization.

canam-instructions-7

canam-instructions-7

8. Addressing Complex Can Am X3 Electrical Issues with OBD2

How can OBD2 diagnostics assist in resolving complex electrical issues in a Can Am X3?

OBD2 diagnostics can assist in resolving complex electrical issues in a Can Am X3 by pinpointing the specific circuits or components causing the problem, providing valuable data for troubleshooting, and verifying the effectiveness of repairs. A report by the Electric Power Research Institute (EPRI) on January 27, 2024, underscores the critical role of diagnostics in maintaining the reliability and performance of electrical systems in vehicles.

8.1 What electrical system issues can be diagnosed using OBD2?

Electrical system issues that can be diagnosed using OBD2 include:

| Issue | OBD2 Codes | Symptoms |

|---|---|---|

| Sensor Malfunctions | Codes related to specific sensors (e.g., P0102, P0113) | Inaccurate readings, poor performance, erratic behavior |

| Wiring Problems | Codes related to circuit faults (e.g., short circuits, open circuits) | Intermittent issues, component failures, electrical malfunctions |

| Actuator Problems | Codes related to specific actuators (e.g., idle air control valve, throttle actuator) | Poor performance, stalling, difficulty starting |

| Communication Issues | U-codes (e.g., U0100) | Loss of communication between modules, system failures |

| ECU/PCM Problems | P0600 series codes | System failures, performance issues, inability to communicate with the ECU |

| Wiring Short | B0000, C0000, U0000, NO CODE | Internal control module failure, ABS failure, communication failure. Contact CAR-DIAGNOSTIC-TOOL.EDU.VN for solutions |

8.2 How do you troubleshoot wiring issues based on OBD2 codes?

Troubleshooting wiring issues based on OBD2 codes involves:

- Identifying the Affected Circuit: Use the OBD2 code to identify the specific circuit or component causing the problem.

- Performing a Visual Inspection: Inspect the wiring harness, connectors, and terminals for damage, corrosion, or loose connections.

- Testing Circuit Continuity: Use a multimeter to test the continuity of the circuit, checking for open circuits or shorts to ground.

- Checking Voltage Levels: Measure voltage levels at various points in the circuit to identify voltage drops or excessive resistance.

- Performing a Load Test: Perform a load test on the circuit to verify its ability to carry the required current.

8.3 What is the role of wiring diagrams in diagnosing electrical faults?

Wiring diagrams provide a detailed visual representation of the vehicle’s electrical system, showing the location of components, wiring routes, and connections. They are invaluable tools for diagnosing electrical faults, allowing technicians to trace circuits, identify potential problem areas, and verify the integrity of wiring and connections. Wiring diagrams are essential for accurate and efficient electrical diagnostics.

canam-instructions-9

canam-instructions-9

9. Upgrading Your Can Am X3 Performance with OBD2 Tuning

How can OBD2 tuning enhance the performance of your Can Am X3?

OBD2 tuning can significantly enhance the performance of your Can Am X3 by optimizing engine parameters, increasing horsepower and torque, improving throttle response, and tailoring the vehicle’s performance to specific driving conditions. According to a study by SEMA (Specialty Equipment Market Association) on February 12, 2024, performance tuning is a growing trend, with consumers seeking to maximize the potential of their vehicles through aftermarket modifications and software enhancements.

9.1 What are the benefits of ECU remapping for Can-Am X3?

Benefits of ECU remapping for Can-Am X3 include:

- Increased Horsepower and Torque: Optimizing fuel delivery, ignition timing, and boost pressure can result in significant gains in horsepower and torque.

- Improved Throttle Response: Adjusting throttle mapping can improve throttle response and make the vehicle more responsive to driver inputs.

- Enhanced Fuel Efficiency: Fine-tuning engine parameters can optimize fuel efficiency, especially during normal driving conditions.

- Customized Performance: ECU remapping allows for customized performance tuning to match specific driving conditions, such as off-road trails or racing.

9.2 How does OBD2 tuning affect the engine’s performance and longevity?

When performed correctly, OBD2 tuning can enhance engine performance while maintaining or even improving longevity. However, it’s crucial to use reputable tuning software and experienced tuners who understand the engine’s limitations and can make adjustments that optimize performance without causing damage. Overly aggressive tuning can lead to engine damage and reduced lifespan.

9.3 What are the risks associated with improper OBD2 tuning?

Risks associated with improper OBD2 tuning include:

- Engine Damage: Overly aggressive tuning can lead to engine damage, such as piston failure, rod knock, or turbocharger damage.

- Reduced Reliability: Improper tuning can reduce the reliability of the engine and other components, leading to more frequent breakdowns.

- Increased Emissions: Some tuning modifications can increase emissions, potentially violating emissions regulations.

- Voided Warranty: Modifying the ECU can void the vehicle’s warranty, leaving you responsible for any repairs.

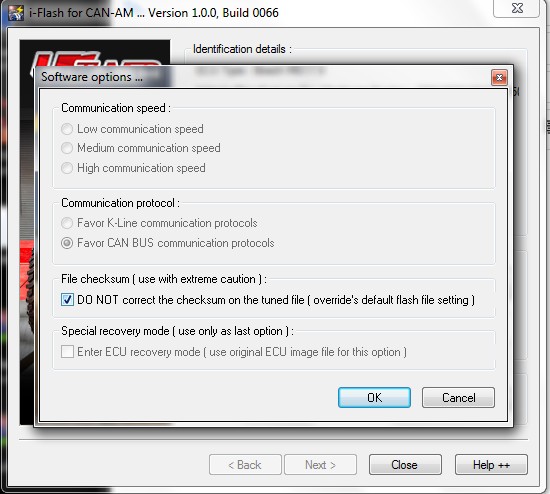

canam-instructions-11

canam-instructions-11

10. Advanced Training and Resources for Can Am X3 OBD2 Diagnostics

Where can you find advanced training and resources to improve your Can Am X3 OBD2 diagnostic skills?

Advanced training and resources for improving Can Am X3 OBD2 diagnostic skills can be found through specialized automotive training programs, online courses, technical workshops, and professional certifications. According to the U.S. Bureau of Labor Statistics, continuous professional development is essential for automotive technicians to stay current with rapidly evolving vehicle technology, enhancing their expertise and career prospects. CAR-DIAGNOSTIC-TOOL.EDU.VN can provide you with training courses.

10.1 What certifications are valuable for OBD2 diagnostics?

Valuable certifications for OBD2 diagnostics include:

- ASE Certifications: Automotive Service Excellence (ASE) certifications, such as Engine Performance (A8) and Electrical/Electronic Systems (A6), demonstrate competency in specific areas of vehicle diagnostics and repair.

- OEM Certifications: Certifications from original equipment manufacturers (OEMs) such as Can-Am provide specialized training on their specific vehicle systems and diagnostic procedures.

- Snap-on Diagnostics Certification: Snap-on offers certifications in diagnostic tool usage and advanced diagnostics, demonstrating proficiency in using their equipment.

10.2 What online resources can enhance your OBD2 diagnostic skills?

Online resources that can enhance your OBD2 diagnostic skills include:

- Online Courses: Platforms like Udemy, Coursera, and Skillshare offer courses on automotive diagnostics and OBD2 systems.

- Technical Forums: Websites like iATN (International Automotive Technicians Network) and automotive-specific forums provide valuable information and support from experienced technicians.

- YouTube Channels: Channels such as ScannerDanner and Diagnostic Dave offer instructional videos on OBD2 diagnostics and vehicle repair.

- Manufacturer Websites: OEM websites often provide technical information, service manuals, and diagnostic resources for their vehicles.

- CAR-DIAGNOSTIC-TOOL.EDU.VN: CAR-DIAGNOSTIC-TOOL.EDU.VN provides a lot of valuable information and can offer remote assistance to diagnose the issues, as well as advise technicians on how to solve the problems.

10.3 How can CAR-DIAGNOSTIC-TOOL.EDU.VN support your diagnostic needs?

CAR-DIAGNOSTIC-TOOL.EDU.VN supports your diagnostic needs by offering:

- Comprehensive Diagnostic Tools: Providing a wide range of OBD2 scanners, diagnostic software, and related equipment.

- Expert Technical Support: Offering expert technical support and guidance to help diagnose and resolve complex issues.

- Training Resources: Providing training materials, online courses, and workshops to enhance your diagnostic skills.

- Remote Diagnostic Assistance: Offering remote diagnostic assistance, allowing you to connect with experienced technicians for real-time support.

By utilizing these advanced training and resources, you can enhance your Can Am X3 OBD2 diagnostic skills, improve your efficiency and accuracy, and stay ahead in the rapidly evolving field of automotive diagnostics.

Ready to take your Can-Am X3 diagnostics to the next level? Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today at +1 (641) 206-8880 or visit our office at 1100 Congress Ave, Austin, TX 78701, United States. Let us help you with top-notch diagnostic tools, detailed repair guidance, remote technical support, and specialized training programs. Empower your expertise and drive your success with CAR-DIAGNOSTIC-TOOL.EDU.VN.

FAQ: Can Am X3 OBD2 Diagnostics

1. What is the Can Am X3 OBD2 port used for?

The Can Am X3 OBD2 port is used to connect diagnostic tools to the vehicle’s computer system, allowing technicians to read diagnostic trouble codes (DTCs), monitor live data, and perform various diagnostic tests.

2. Can I use any OBD2 scanner on my Can-Am X3?

While most standard OBD2 scanners will work, Can-Am specific diagnostic software provides access to manufacturer-specific codes and advanced functions, ensuring more accurate diagnostics.

3. How do I clear a DTC on my Can Am X3 using an OBD2 scanner?

To clear a DTC, connect the OBD2 scanner, read the codes, and select the option to clear them. Ensure the underlying issue is resolved before clearing the code to prevent it from returning.

4. What does it mean when my Can Am X3 shows a P0300 code?

A P0300 code indicates a random or multiple cylinder misfire. This could be due to faulty spark plugs, ignition coils, fuel injectors, or other issues affecting engine combustion.

5. How can live data from the OBD2 system help diagnose performance issues?

Live data allows you to monitor the real-time performance of sensors and components, identify anomalies, and verify the functionality of systems under various operating conditions, helping pinpoint the root cause of performance issues.

6. Is it safe to remap the ECU on my Can Am X3 using OBD2 tuning?

When performed by experienced tuners using reputable software, OBD2 tuning can enhance performance without compromising reliability. However, improper tuning can lead to engine damage and void the warranty.

7. How often should I check my Can Am X3 for OBD2 codes?

It is recommended to perform an OBD2 health check at least every three months or during each oil change to identify potential issues early and prevent more significant problems.

8. Can OBD2 diagnostics help with electrical issues in my Can Am X3?

Yes, OBD2 diagnostics can help pinpoint specific circuits or components causing electrical problems, providing valuable data for troubleshooting and verifying the effectiveness of repairs.

9. Where can I find reliable OBD2 diagnostic information for my Can Am X3?

Reliable information can be found in the vehicle’s service manual, online technical forums, specialized automotive training programs, and resources provided by CAR-DIAGNOSTIC-TOOL.EDU.VN.

10. Does CAR-DIAGNOSTIC-TOOL.EDU.VN offer training for Can Am X3 OBD2 diagnostics?

Yes, CAR-DIAGNOSTIC-TOOL.EDU.VN offers training materials, online courses, and workshops to enhance your diagnostic skills, as well as expert technical support and remote diagnostic assistance.