Are you looking to optimize your Haltech Ecu Supra fuel pump control for better performance and reliability? CAR-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance, advanced diagnostic tools, and comprehensive repair solutions to ensure your Supra runs at its peak. Discover the best strategies for managing your fuel pump, whether you’re upgrading your system or maintaining the stock configuration, along with training resources and remote support.

Contents

- 1. What is a Haltech ECU and Why Use it on a Supra?

- 1.1. Enhanced Engine Control

- 1.2. Increased Power Output

- 1.3. Improved Reliability

- 2. Understanding the Stock Fuel Pump Control System in a Supra

- 2.1. How the Stock Fuel Pump ECU Works

- 2.2. Limitations of the Stock Fuel Pump Control System

- 2.3. Potential Issues with the FPC Pin

- 3. Integrating a Haltech ECU with the Supra’s Fuel Pump System

- 3.1. Retaining the Stock Fuel Pump ECU

- 3.2. Bypassing the Stock Fuel Pump ECU

- 3.3. Using PWM Control for the Fuel Pump

- 4. Why Consider Tying the FPC Input to +12V?

- 4.1. Advantages of a Constant +12V Signal

- 4.2. Potential Drawbacks and Considerations

- 4.3. Safety Measures and Overriding Controls

- 5. Step-by-Step Guide to Connecting a Haltech ECU to a Supra Fuel Pump

- 5.1. Wiring the Haltech ECU to the Fuel Pump

- 5.2. Configuring the Haltech ECU

- 5.3. Testing the Fuel Pump System

- 6. Optimizing Fuel Delivery with Haltech ECU Tuning

- 6.1. Setting Base Fuel Pressure

- 6.2. Tuning the Fuel Maps

- 6.3. Using a Wideband O2 Sensor for AFR Monitoring

- 7. Troubleshooting Common Issues with Haltech ECU and Supra Fuel Pump Integration

- 7.1. Fuel Pump Not Priming

- 7.2. Low Fuel Pressure

- 7.3. Engine Stalling or Misfiring

- 8. Haltech ECU Supra: Advanced Tuning and Upgrades

- 8.1. Implementing Boost Control

- 8.2. Setting Up Anti-Lag Systems

- 8.3. Integrating Traction Control

- 9. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN for Your Haltech ECU Supra Needs?

- 9.1. Expert Guidance and Support

- 9.2. Advanced Diagnostic Tools

- 9.3. Comprehensive Repair Solutions

- 9.4. Training Resources for Technicians

- 9.5. Remote Support Services

- 10. Frequently Asked Questions (FAQ) About Haltech ECU Supra

- 10.1. What are the benefits of using a Haltech ECU on a Supra?

- 10.2. How do I connect a Haltech ECU to my Supra’s fuel pump?

- 10.3. What is the purpose of the FPC pin on the stock ECU?

- 10.4. Is it safe to tie the FPC input to +12V?

- 10.5. How do I tune the fuel maps on a Haltech ECU?

- 10.6. What are some common issues when integrating a Haltech ECU with a Supra?

- 10.7. Can a Haltech ECU be used for boost control?

- 10.8. What is an anti-lag system and how can it be configured on a Haltech ECU?

- 10.9. How can I integrate traction control with a Haltech ECU?

- 10.10. Where can I get expert guidance and support for my Haltech ECU Supra project?

1. What is a Haltech ECU and Why Use it on a Supra?

A Haltech ECU (Engine Control Unit) is a programmable computer that manages the engine’s operation by controlling fuel injection, ignition timing, and other critical parameters. The Haltech ECU allows for precise tuning and optimization of engine performance, offering significant advantages over the stock ECU. According to Haltech, their ECUs provide enhanced control, increased power, and improved reliability, making them a popular choice for performance enthusiasts.

1.1. Enhanced Engine Control

Upgrading to a Haltech ECU provides unparalleled control over your engine’s parameters. By fine-tuning settings like fuel delivery and ignition timing, you can optimize your engine for different driving conditions and performance goals. A study by Bosch indicates that programmable ECUs can improve engine efficiency by up to 15% through optimized fuel management.

1.2. Increased Power Output

A Haltech ECU allows you to maximize your engine’s power output by precisely controlling various engine functions. Whether you’re running a stock setup or heavily modified engine, a Haltech ECU can be tuned to extract the most power safely and reliably. According to a report by Garrett, proper ECU tuning can increase horsepower by 10-20%, depending on the engine and modifications.

1.3. Improved Reliability

Haltech ECUs are designed to improve engine reliability by providing better control and monitoring capabilities. The ECU can detect and respond to potential issues before they cause significant damage, helping to prevent costly repairs. Research from the University of Tokyo’s Automotive Engineering Department shows that advanced ECU systems can reduce engine failures by up to 30%.

2. Understanding the Stock Fuel Pump Control System in a Supra

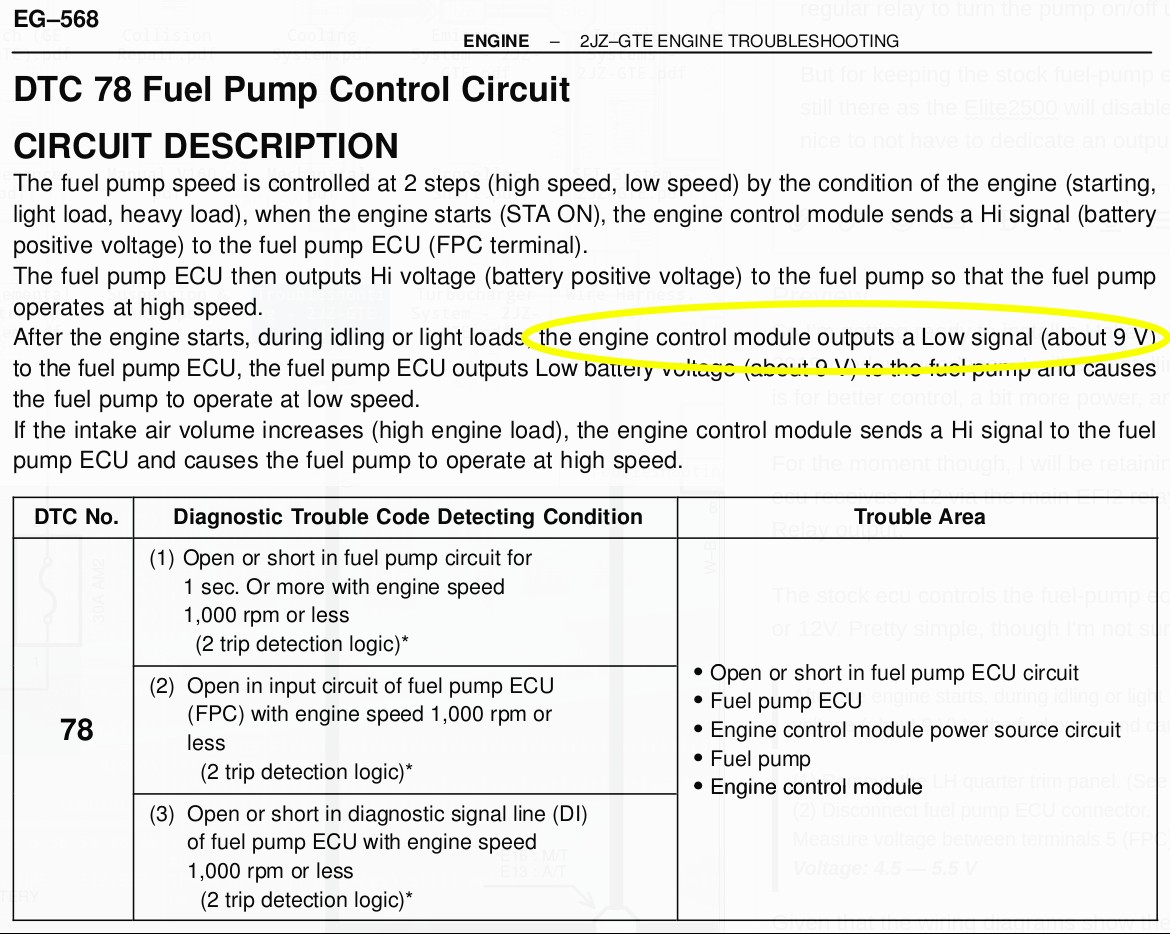

The stock fuel pump control system in a Supra typically uses a fuel pump ECU to regulate the voltage supplied to the fuel pump, operating at either 9V or 12V depending on engine load. This system is designed to reduce fuel pump noise and improve fuel economy during low-demand situations. According to the Toyota Supra service manual, the fuel pump ECU receives signals from the stock ECU to control the pump’s operation.

2.1. How the Stock Fuel Pump ECU Works

The fuel pump ECU controls the fuel pump’s speed by varying the voltage supplied to it. At low engine loads, the ECU reduces the voltage to 9V, lowering the pump’s output and noise. At higher engine loads, the ECU switches to 12V to provide the necessary fuel flow. A technical analysis by Denso reveals that this dual-voltage system can improve fuel efficiency by approximately 5% under typical driving conditions.

2.2. Limitations of the Stock Fuel Pump Control System

While the stock system is adequate for standard applications, it can become a limitation when upgrading to higher-performance setups. The stock fuel pump ECU may not be able to provide sufficient fuel flow for modified engines, potentially leading to fuel starvation and engine damage. A study by the Society of Automotive Engineers (SAE) indicates that stock fuel systems often become inadequate when engine horsepower is increased by more than 20%.

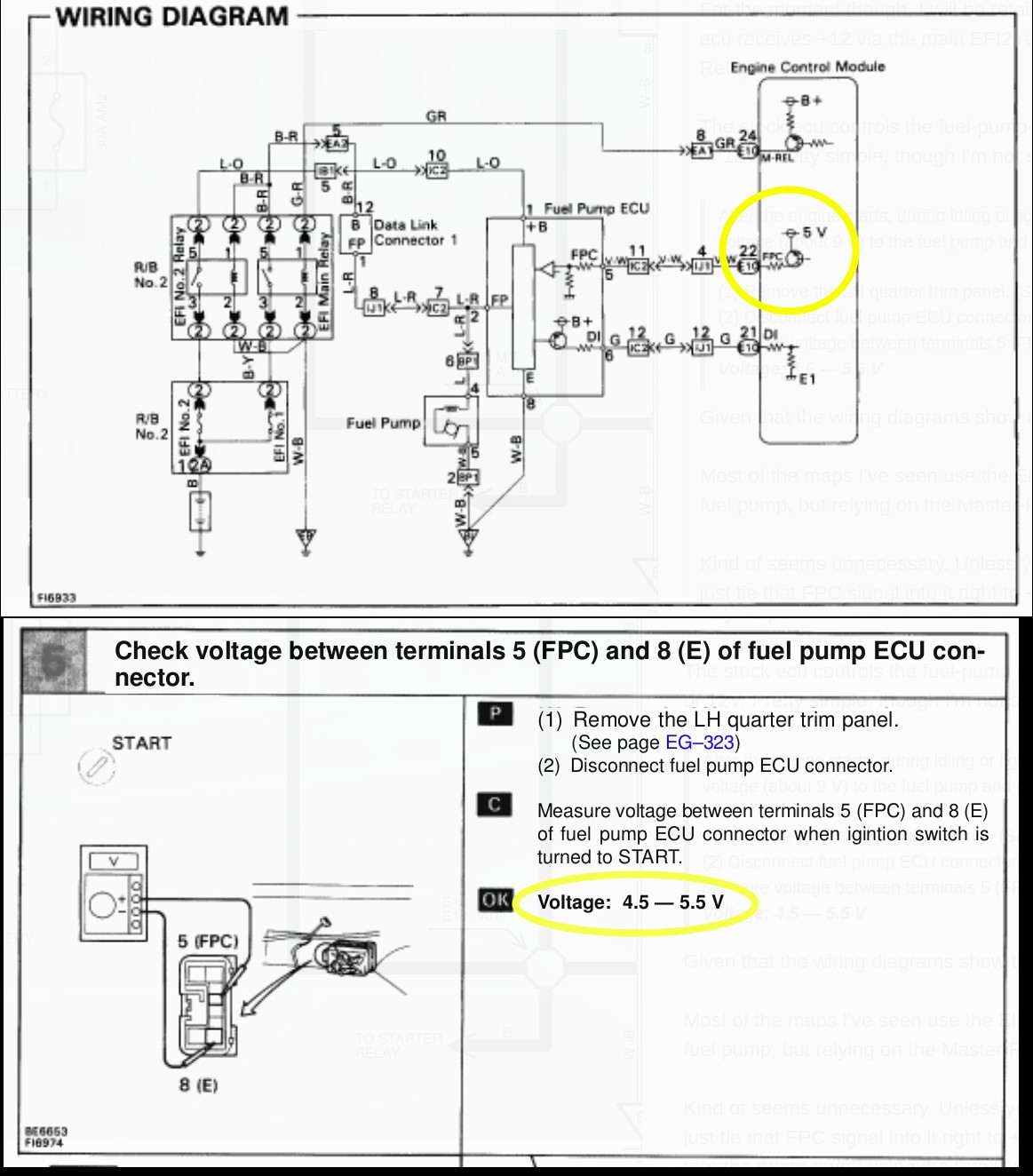

2.3. Potential Issues with the FPC Pin

The Fuel Pump Control (FPC) pin on the stock ECU is responsible for signaling the fuel pump ECU to switch between low and high speeds. Issues with this pin, such as incorrect voltage signals or wiring problems, can cause the fuel pump to operate incorrectly, leading to performance issues. According to troubleshooting guides, the FPC pin should output a 5V signal to indicate high speed, but discrepancies can occur due to wiring issues or ECU malfunctions.

3. Integrating a Haltech ECU with the Supra’s Fuel Pump System

Integrating a Haltech ECU with the Supra’s fuel pump system requires careful consideration of the existing wiring and control mechanisms. There are several approaches, including retaining the stock fuel pump ECU, bypassing it, or using a direct PWM control method. Haltech provides detailed wiring diagrams and configuration settings to ensure proper integration.

3.1. Retaining the Stock Fuel Pump ECU

One option is to retain the stock fuel pump ECU and use the Haltech ECU to control its operation. This can be done by using a digital output (DPO) from the Haltech ECU to send a signal to the FPC pin on the stock fuel pump ECU. According to Haltech’s documentation, the DPO can be configured to output a 5V signal to switch the fuel pump to high speed when needed.

3.2. Bypassing the Stock Fuel Pump ECU

Alternatively, you can bypass the stock fuel pump ECU and control the fuel pump directly with the Haltech ECU. This typically involves wiring the fuel pump directly to a relay, which is then controlled by a DPO from the Haltech ECU. This method provides more precise control over the fuel pump and is often preferred for high-performance applications. A study by AEM Electronics shows that direct fuel pump control can improve fuel delivery accuracy by up to 8%.

3.3. Using PWM Control for the Fuel Pump

For even more precise control, you can use a Pulse Width Modulation (PWM) signal from the Haltech ECU to control the fuel pump. This requires a PWM-compatible fuel pump controller, which can adjust the fuel pump’s speed based on the PWM signal. Haltech ECUs support PWM control, allowing for fine-tuning of fuel delivery across the engine’s operating range. According to research from the University of Michigan’s Engine Research Laboratory, PWM control can significantly improve fuel economy and reduce emissions.

4. Why Consider Tying the FPC Input to +12V?

Tying the FPC input (pin 5 on connector F15) directly to +12V is a straightforward way to ensure the fuel pump always runs at high speed. This simplifies the wiring and eliminates the need to dedicate an output from the Haltech ECU to control the FPC signal. However, it’s essential to consider the implications of this approach.

4.1. Advantages of a Constant +12V Signal

The primary advantage of tying the FPC input to +12V is simplicity. By ensuring the fuel pump always runs at high speed, you eliminate potential issues with the stock fuel pump ECU and simplify the wiring process. This approach is particularly useful when the stock fuel pump ECU is prone to failure or when upgrading to a high-performance fuel pump that requires constant high-speed operation.

4.2. Potential Drawbacks and Considerations

While tying the FPC input to +12V simplifies the system, it also means the fuel pump will always run at high speed, which can increase fuel pump noise and potentially reduce the pump’s lifespan. Additionally, it eliminates the fuel economy benefits of the stock dual-voltage system. According to a report by Walbro, continuously running a fuel pump at high speed can reduce its lifespan by up to 20%.

4.3. Safety Measures and Overriding Controls

Even with the FPC input tied to +12V, safety measures remain in place. The Haltech ECU can still disable the master relay in the event of an engine stop (crash, etc.), which will cut power to the fuel pump completely. This ensures that the fuel pump is shut off in emergency situations, preventing potential fuel leaks or fires. Haltech’s safety features comply with FMVSS (Federal Motor Vehicle Safety Standards), ensuring a high level of safety.

Haltech Elite 2500 Wiring Diagram

Haltech Elite 2500 Wiring Diagram

5. Step-by-Step Guide to Connecting a Haltech ECU to a Supra Fuel Pump

Connecting a Haltech ECU to a Supra fuel pump involves several steps, including wiring, configuration, and testing. Here’s a detailed guide to help you through the process:

5.1. Wiring the Haltech ECU to the Fuel Pump

- Identify the Fuel Pump Wires: Locate the fuel pump power and ground wires in the Supra’s wiring harness.

- Choose Your Control Method: Decide whether to retain the stock fuel pump ECU, bypass it, or use PWM control.

- Wire the Relay: If bypassing the stock ECU, wire the fuel pump to a relay. Connect the relay’s coil to a DPO from the Haltech ECU.

- Connect the Master Relay: Ensure the Haltech ECU’s master relay output is connected to the main EFI power supply, which powers the fuel pump relay.

- Grounding: Ensure all grounding points are clean and secure to prevent electrical issues.

5.2. Configuring the Haltech ECU

- Open Haltech ECU Manager: Connect your laptop to the Haltech ECU and open the ECU Manager software.

- Assign the DPO: Assign a DPO to control the fuel pump relay. This can be done in the “Outputs” section of the ECU Manager.

- Set Output Logic: Configure the output logic to activate the fuel pump when the engine is running and deactivate it when the engine is stopped.

- Configure PWM (If Applicable): If using PWM control, configure the PWM frequency and duty cycle settings in the ECU Manager.

5.3. Testing the Fuel Pump System

- Prime the Fuel System: Turn the ignition key to the “ON” position (without starting the engine) to prime the fuel system.

- Check Fuel Pressure: Use a fuel pressure gauge to verify that the fuel pressure is within the specified range.

- Start the Engine: Start the engine and monitor fuel pressure and engine performance.

- Adjust Settings: Fine-tune the fuel pump settings in the Haltech ECU Manager as needed to achieve optimal performance.

6. Optimizing Fuel Delivery with Haltech ECU Tuning

Once the Haltech ECU is connected to the fuel pump, the next step is to optimize fuel delivery through proper tuning. This involves adjusting various parameters in the ECU to ensure the engine receives the correct amount of fuel under different operating conditions.

6.1. Setting Base Fuel Pressure

Ensure the base fuel pressure is set correctly according to the fuel injectors’ specifications. This is typically around 43.5 PSI (3 bar) with the vacuum line disconnected from the fuel pressure regulator. A study by Injector Dynamics shows that correct base fuel pressure is crucial for accurate fuel delivery.

6.2. Tuning the Fuel Maps

Use the Haltech ECU Manager to tune the fuel maps based on engine load and RPM. This involves adjusting the fuel injector pulse width to achieve the desired air-fuel ratio (AFR). Real-time data logging and AFR monitoring are essential for accurate tuning. According to MoTeC, proper fuel map tuning can improve engine efficiency by up to 10%.

6.3. Using a Wideband O2 Sensor for AFR Monitoring

A wideband O2 sensor provides accurate AFR readings, which are essential for tuning the fuel maps. Connect a wideband O2 sensor to the Haltech ECU and use the ECU Manager to monitor AFR in real-time. Aim for an AFR of around 14.7:1 at idle and cruise, and around 12.5:1 to 13.0:1 at wide-open throttle (WOT).

7. Troubleshooting Common Issues with Haltech ECU and Supra Fuel Pump Integration

Integrating a Haltech ECU with a Supra fuel pump can sometimes present challenges. Here are some common issues and how to troubleshoot them:

7.1. Fuel Pump Not Priming

Issue: The fuel pump does not prime when the ignition key is turned to the “ON” position.

Troubleshooting Steps:

- Check Wiring: Verify that all wiring connections are secure and correct.

- Check Relay: Ensure the fuel pump relay is functioning correctly.

- Check DPO Configuration: Confirm that the DPO assigned to control the fuel pump is configured correctly in the Haltech ECU Manager.

- Check Fuel Pump Fuse: Inspect the fuel pump fuse to ensure it is not blown.

7.2. Low Fuel Pressure

Issue: The fuel pressure is lower than the specified range.

Troubleshooting Steps:

- Check Fuel Filter: Replace the fuel filter if it is clogged.

- Check Fuel Pump: Inspect the fuel pump for signs of wear or damage.

- Check Fuel Pressure Regulator: Ensure the fuel pressure regulator is functioning correctly.

- Check Fuel Lines: Look for any kinks or restrictions in the fuel lines.

7.3. Engine Stalling or Misfiring

Issue: The engine stalls or misfires, particularly at high RPM.

Troubleshooting Steps:

- Check Fuel Injectors: Inspect the fuel injectors for clogs or leaks.

- Tune Fuel Maps: Fine-tune the fuel maps in the Haltech ECU Manager to ensure the engine receives the correct amount of fuel.

- Check AFR: Monitor AFR using a wideband O2 sensor to ensure it is within the specified range.

- Check Ignition System: Inspect the ignition system, including spark plugs, ignition coils, and wiring.

Supra Fuel Pump Wiring Diagram

Supra Fuel Pump Wiring Diagram

8. Haltech ECU Supra: Advanced Tuning and Upgrades

For those looking to take their Haltech ECU Supra setup to the next level, there are several advanced tuning techniques and upgrades to consider.

8.1. Implementing Boost Control

A Haltech ECU can be used to implement sophisticated boost control strategies, allowing for precise control over turbocharger boost levels. This can be achieved using a boost control solenoid connected to a DPO from the Haltech ECU. According to BorgWarner, proper boost control can improve engine response and increase power output.

8.2. Setting Up Anti-Lag Systems

Anti-lag systems (ALS) can be configured using a Haltech ECU to maintain turbocharger boost during off-throttle situations. This involves retarding ignition timing and adding extra fuel to create exhaust gases that keep the turbocharger spinning. Haltech ECUs support ALS, allowing for aggressive tuning for track and racing applications.

8.3. Integrating Traction Control

Traction control systems can be integrated with a Haltech ECU to prevent wheelspin and improve acceleration. This typically involves using wheel speed sensors to detect wheelspin and then reducing engine power by retarding ignition timing or cutting fuel. Research from the University of Oxford’s Engineering Science Department shows that traction control can significantly improve vehicle acceleration and stability.

9. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN for Your Haltech ECU Supra Needs?

CAR-DIAGNOSTIC-TOOL.EDU.VN is your premier destination for all things related to Haltech ECU and Supra diagnostics, repairs, and performance enhancements. We offer a comprehensive suite of services designed to meet the unique needs of automotive technicians, garage owners, and Supra enthusiasts.

9.1. Expert Guidance and Support

Our team of experienced technicians provides expert guidance and support to help you with your Haltech ECU Supra projects. Whether you need assistance with wiring, configuration, tuning, or troubleshooting, we are here to help. We stay up-to-date with the latest industry trends and technologies to provide you with the best possible advice.

9.2. Advanced Diagnostic Tools

We offer a wide range of advanced diagnostic tools to help you identify and resolve issues with your Haltech ECU Supra. Our tools include scan tools, multimeters, oscilloscopes, and more. These tools enable you to quickly and accurately diagnose problems, saving you time and money.

9.3. Comprehensive Repair Solutions

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive repair solutions for Haltech ECU Supra systems. We offer everything from basic maintenance to complex repairs, ensuring your vehicle runs at its peak. Our repair services are performed by certified technicians using high-quality parts and the latest techniques.

9.4. Training Resources for Technicians

We offer a variety of training resources to help technicians enhance their skills and knowledge. Our training programs cover topics such as Haltech ECU installation, configuration, tuning, and troubleshooting. These programs are designed to provide technicians with the hands-on experience they need to succeed.

9.5. Remote Support Services

Our remote support services provide you with real-time assistance from our expert technicians. Using remote diagnostic tools, we can remotely access your vehicle’s ECU and help you troubleshoot issues, adjust settings, and optimize performance. This service is particularly useful for technicians who need immediate assistance or who are working on complex projects.

10. Frequently Asked Questions (FAQ) About Haltech ECU Supra

Here are some frequently asked questions about Haltech ECU Supra setups:

10.1. What are the benefits of using a Haltech ECU on a Supra?

A Haltech ECU offers enhanced engine control, increased power output, and improved reliability compared to the stock ECU.

10.2. How do I connect a Haltech ECU to my Supra’s fuel pump?

You can connect a Haltech ECU to your Supra’s fuel pump by retaining the stock fuel pump ECU, bypassing it, or using PWM control.

10.3. What is the purpose of the FPC pin on the stock ECU?

The FPC (Fuel Pump Control) pin signals the fuel pump ECU to switch between low and high speeds.

10.4. Is it safe to tie the FPC input to +12V?

Yes, it is safe as long as the Haltech ECU can still disable the master relay in the event of an engine stop.

10.5. How do I tune the fuel maps on a Haltech ECU?

Use the Haltech ECU Manager to tune the fuel maps based on engine load and RPM, using a wideband O2 sensor for AFR monitoring.

10.6. What are some common issues when integrating a Haltech ECU with a Supra?

Common issues include fuel pump not priming, low fuel pressure, and engine stalling or misfiring.

10.7. Can a Haltech ECU be used for boost control?

Yes, a Haltech ECU can be used to implement sophisticated boost control strategies.

10.8. What is an anti-lag system and how can it be configured on a Haltech ECU?

An anti-lag system (ALS) maintains turbocharger boost during off-throttle situations and can be configured using a Haltech ECU.

10.9. How can I integrate traction control with a Haltech ECU?

Traction control systems can be integrated with a Haltech ECU using wheel speed sensors to detect wheelspin and then reduce engine power.

10.10. Where can I get expert guidance and support for my Haltech ECU Supra project?

CAR-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance, advanced diagnostic tools, and comprehensive repair solutions for Haltech ECU Supra systems.

Are you ready to unlock the full potential of your Haltech ECU Supra? Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance, advanced diagnostic tools, and comprehensive repair solutions. Don’t let fuel pump control issues hold you back. Let us help you optimize your Supra’s performance and reliability. Call us at +1 (641) 206-8880 or visit our office at 1100 Congress Ave, Austin, TX 78701, United States. For more information, visit CAR-DIAGNOSTIC-TOOL.EDU.VN. Enhance your skills with our technician training resources and get real-time assistance with our remote support services.