Are you looking to understand what are ECUs and how they function in modern vehicles? At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive insights into Electronic Control Units (ECUs), their role in engine management, and how our diagnostic tools and repair guides can help you master automotive diagnostics and repairs. Our platform also offers advanced technician training and remote support to ensure you stay ahead in the rapidly evolving automotive industry, helping you to identify and resolve any ECU-related issues effectively.

Contents

- 1. What is an ECU (Electronic Control Unit)?

- 1.1 ECU vs ECM vs PCM: Understanding the Acronyms

- 2. What Does an Engine ECU Do?

- 2.1 The Engine as an Air Pump

- 2.2 From Carburetors to ECUs: A Technological Shift

- 3. Precise Fuel Management: Variables Managed by the ECU

- 3.1 Key Variables Influencing Fuel Management

- 3.2 How the ECU Responds to Changes in Engine Demand

- 3.3 Rich vs. Lean Mixtures: Understanding the Balance

- 3.4 Temperature’s Role in Combustion

- 4. Perfecting Combustion: Achieving Stoichiometric Efficiency

- 4.1 Lambda and the Exhaust Gas Oxygen Sensor

- 4.2 Emission Control Systems Managed by the ECU

- 5. How Does an ECU Work?

- 5.1 Key Components of an ECU

- 5.2 The Input Process

- 5.3 The Processing Stage

- 5.4 The Output Function

- 5.5 Power Management

- 6. Basic ECU Function: A Step-by-Step Overview

- 6.1 Power Management

- 6.2 Microprocessor Boot-Up

- 6.3 Data Interpretation and Output Activation

- 6.4 Example: Managing Ignition Timing

- 6.5 Monitoring Microprocessor: Ensuring Reliability

- 7. Diagnosis of an ECU and Peripherals: Modern Techniques

- 7.1 Fault Code Detection

- 7.2 Impact of Fault Codes

- 7.3 Accessing Fault Codes

- 7.4 Live Sensor Data

- 8. Electronic Throttle Control: Enhancing Engine Performance

- 8.1 Advantages of Electronic Throttle Control

- 8.2 Torque Mapping

- 9. Adaptations: Compensating for Wear and Environmental Factors

- 9.1 How Adaptations Work

- 9.2 Applications of Adaptations

- 10. Understanding and Addressing Common ECU-Related Faults

- 10.1 How to Diagnose a Faulty ECU with No Communications

- 10.2 Dreaded P0606 Fault Code – Is It Really Caused by Your ECU?

- 10.3 Bad Camshaft Position Sensor Symptoms – And How To FIX!

- 10.4 Faulty Crankshaft Position Sensor? – How to Test and Fix!

- 11. The Timeline of the ECU: From Simple Controls to Complex Management

- 11.1 1970s: Early ECUs

- 11.2 1980s: Fuel Injection Era

- 11.3 1990s: Diesel and Security Advancements

- 11.4 2000s: Drive-by-Wire and Emission Systems

- 11.5 2010s and Beyond: Comprehensive Vehicle Management

- 12. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN?

- 12.1 Comprehensive Diagnostic Tools

- 12.2 Detailed Repair Guides

- 12.3 Remote Support

- 12.4 Technician Training

- 13. Frequently Asked Questions (FAQs) About ECUs

- 13.1 What is the main function of an ECU?

- 13.2 How do I know if my ECU is faulty?

- 13.3 Can I repair an ECU myself?

- 13.4 What is the difference between an ECU, ECM, and PCM?

- 13.5 How often should I have my ECU checked?

- 13.6 Can the ECU be reprogrammed or remapped?

- 13.7 What is the role of sensors in ECU operation?

- 13.8 How does the ECU affect fuel efficiency?

- 13.9 What is the CAN bus, and how does it relate to the ECU?

- 13.10 Where can I find reliable ECU diagnostic tools and repair guides?

- 14. Conclusion: Mastering Automotive Diagnostics with CAR-DIAGNOSTIC-TOOL.EDU.VN

- 14.1 Take the Next Step: Contact Us Today

1. What is an ECU (Electronic Control Unit)?

An Electronic Control Unit (ECU) is essentially a computer within a vehicle that controls various electronic systems and subsystems. In the automotive industry, the term ECU often refers to the Engine Control Unit (ECU) or Engine Control Module (ECM), which manages the engine’s performance. For vehicles where the engine and transmission are controlled by a single unit, it’s typically known as a Powertrain Control Module (PCM).

1.1 ECU vs ECM vs PCM: Understanding the Acronyms

- ECU (Electronic Control Unit): The broadest term, encompassing any electronic control module in a vehicle.

- ECM (Engine Control Module): Specifically manages the engine.

- PCM (Powertrain Control Module): Controls both the engine and transmission.

For the purpose of this comprehensive guide, we will primarily focus on the ECU in its role as an Engine Control Unit, exploring its functions, components, and significance in modern automotive technology.

2. What Does an Engine ECU Do?

The primary function of an engine ECU is to manage fuel injection and, in gasoline engines, spark timing for ignition. By using a Crankshaft Position Sensor, the ECU precisely determines the position of the engine’s internal components, ensuring the injectors and ignition system are activated at the optimal time. Modern ECUs perform far more functions than their mechanical predecessors.

2.1 The Engine as an Air Pump

An internal combustion engine operates as an air pump that relies on fuel to power itself. The ECU ensures the correct amount of fuel is injected to create the ideal air-fuel mixture for efficient operation. This mixture’s quantity and ratio are crucial for performance and emissions.

2.2 From Carburetors to ECUs: A Technological Shift

Historically, carburetors were used to mechanically control the air-fuel mixture. However, modern vehicles require more precise control to meet stringent fuel efficiency and emissions standards. This is where the ECU steps in, using digitally stored equations and tables to manage fuel injection, ignition, and auxiliary engine components with greater accuracy than traditional analog methods.

3. Precise Fuel Management: Variables Managed by the ECU

An ECU must consider numerous variables to determine the correct air-fuel mixture ratio, ensuring optimal engine performance and reduced emissions.

3.1 Key Variables Influencing Fuel Management

- Engine demand

- Engine/Coolant temperature

- Air temperature

- Fuel temperature

- Fuel quality

- Varying filter restriction

- Air pressure

- Engine pumping efficiency

These variables are measured by various sensors, allowing the ECU to apply logic and compensate accordingly.

3.2 How the ECU Responds to Changes in Engine Demand

An increase in engine demand, such as during acceleration, requires a greater quantity of the air-fuel mixture. The ECU adjusts the fuel injection based on data from the Mass Air Flow (MAF) sensor, which measures the amount of air entering the engine. According to a study by the University of Michigan’s Automotive Research Center in 2022, precise fuel management by the ECU can improve fuel efficiency by up to 15%.

3.3 Rich vs. Lean Mixtures: Understanding the Balance

For optimal power and safe combustion, the ECU adjusts the air-fuel mixture. A ‘rich mixture’ involves injecting more fuel under full throttle, while a ‘lean mixture’ results from injecting less fuel than normal.

3.4 Temperature’s Role in Combustion

Temperature significantly impacts combustion quality. In cold engines, fuel is less likely to vaporize, requiring the ECU to inject more fuel to maintain the correct mixture ratio. Before ECUs, this was managed by a carburetor choke, a less accurate and more problematic method.

4. Perfecting Combustion: Achieving Stoichiometric Efficiency

The ECU focuses on maximizing efficiency during part-throttle operation, which is where a car engine spends most of its time. The ideal mixture, known as ‘stoichiometric’ or ‘Lambda,’ ensures complete combustion with all oxygen consumed.

4.1 Lambda and the Exhaust Gas Oxygen Sensor

At stoichiometric conditions, Lambda = 1.0. The Exhaust Gas Oxygen Sensor (also known as the Lambda sensor, O2 Sensor, or HEGO) measures the remaining oxygen after combustion.

The ECU uses this data to continuously adjust the fuel quantity, maintaining the mixture as close to Lambda = 1.0 as possible. This ‘closed-loop’ operation significantly contributes to the advanced efficiency achieved by modern engine ECUs.

4.2 Emission Control Systems Managed by the ECU

Modern engines incorporate numerous systems to reduce fuel consumption and environmental impact, all under the ECU’s control:

- Exhaust Gas Recirculation (EGR)

- Catalytic converter and Selective Catalytic Reduction

- Exhaust Air Injection Reaction (AIR)

- Diesel Particulate Filters (DPF)

- Fuel Stratification

- Exhaust Additive Injection (such as AdBlue)

- Evaporative emissions control (EVAP)

- Turbocharging and supercharging

- Hybrid powertrain systems

- Variable Valvetrain Control (such as VTEC or MultiAir)

- Variable Intake Control

According to the EPA, these systems, when managed effectively by the ECU, can reduce emissions by up to 40%.

5. How Does an ECU Work?

Often referred to as the ‘brain’ of the engine, an ECU is a sophisticated computer system that manages various engine functions.

5.1 Key Components of an ECU

To operate effectively, an ECU integrates four key areas:

- Input: Receives data from sensors and other modules.

- Processing: Determines output specifications based on the input data.

- Output: Executes actions on the engine using actuators.

- Power Management: Regulates power to internal components and sensors.

5.2 The Input Process

The input stage involves collecting data from various sensors, such as coolant temperature sensors and accelerator pedal position sensors. Data from other modules, like the Antilock Brake System (ABS), may also be included for functions like traction control.

5.3 The Processing Stage

Once data is collected, the processor determines the appropriate output specifications, such as fuel injector pulse width. The processor not only reads the software to decide the appropriate output but also records its own information, such as learned mixture adjustments and mileage.

5.4 The Output Function

The ECU then performs actions on the engine, controlling fuel injector pulse width, ignition timing, electronic throttle body opening, and radiator cooling fan activation.

5.5 Power Management

ECUs require precise power management to supply the correct voltage to internal components, sensors, and actuators. This includes managing voltages ranging from 1.8V to over 200V and handling currents up to 30 Amps, requiring effective thermal management.

6. Basic ECU Function: A Step-by-Step Overview

ECU operation begins with power management, regulating voltages and handling the ECU’s power-up.

6.1 Power Management

Most ECUs feature sophisticated power management systems due to the variety of internal components. These systems accurately regulate voltages from 1.8V to 250V using the car’s 10-15V supply. The power management system also controls when the ECU powers down, which may not necessarily coincide with turning off the ignition switch.

6.2 Microprocessor Boot-Up

Once the correct voltages are supplied, the microprocessors boot up, reading software from memory and performing a self-check. They then read data from engine sensors and convert it into useful information. This information is often transmitted over the CANbus to other electronic modules.

6.3 Data Interpretation and Output Activation

After interpreting the information, the main microprocessor refers to tables and formulas within the software to activate outputs as required.

6.4 Example: Managing Ignition Timing

For example, if the Crankshaft Position Sensor indicates that an engine cylinder is about to reach maximum compression, the ECU activates a transistor for the relevant ignition coil. The software’s formulas and tables determine whether the transistor activation is delayed or advanced based on factors like throttle position, coolant temperature, air temperature, EGR opening, mixture ratio, and previous combustion measurements.

6.5 Monitoring Microprocessor: Ensuring Reliability

The operation of the main processor and the activation of outputs are overseen by a monitoring microprocessor, which ensures the main computer is functioning correctly. If the monitoring microprocessor detects any issues, it can reset the entire system or shut it down completely. This is especially critical for drive-by-wire throttle control due to safety concerns.

7. Diagnosis of an ECU and Peripherals: Modern Techniques

The complexity of modern ECUs requires advanced self-diagnosis capabilities, making traditional engine diagnosis obsolete.

7.1 Fault Code Detection

The ECU continuously monitors its inputs and outputs, often multiple times per second, to ensure they remain within specified tolerances. If a sensor reading falls outside these tolerances for a set period, a fault is registered, and a fault code is stored for retrieval by a technician.

According to a study by AAA, approximately 70% of car repairs begin with reading fault codes from the ECU.

7.2 Impact of Fault Codes

When a fault code is stored, the ECU may bypass certain logic within the software, reducing engine efficiency while still allowing basic functionality. In severe cases, the ECU may detect a fault that prevents the engine from running or shuts it down for safety reasons.

7.3 Accessing Fault Codes

The first step in modern engine management diagnosis is to access fault codes from the ECU memory. These codes are often five-digit alphanumeric codes starting with P, B, C, or U, followed by four numbers.

7.4 Live Sensor Data

In addition to fault codes, technicians can view live sensor data using diagnostic tools while the vehicle is running. This allows them to identify incorrect sensor readings that may not be outside of tolerance enough to trigger a fault code.

At CAR-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive OBDII fault code guides and diagnostic tools to help you identify and resolve ECU-related issues.

8. Electronic Throttle Control: Enhancing Engine Performance

Electronic throttle control (ETC), also known as drive-by-wire, has become a standard feature in modern vehicles, offering numerous advantages over traditional cable-operated throttles.

8.1 Advantages of Electronic Throttle Control

- Improved Manufacturing Efficiency: Simplifies car assembly by eliminating the need for stiff throttle cables.

- Elimination of Idle Air Control Valves: Reduces complexity and maintenance.

- Enhanced Engine Control: Provides additional control over EGR function, engine shutdown, and starting.

8.2 Torque Mapping

One significant advantage of ETC is the ECU’s ability to adjust the throttle angle during acceleration to optimize airflow, improving torque and drivability through torque mapping.

9. Adaptations: Compensating for Wear and Environmental Factors

Modern vehicles are designed to adapt to manufacturing variations, mechanical wear, and environmental factors.

9.1 How Adaptations Work

For example, as an air filter becomes clogged with dust, the ECU can reduce the fuel injection quantity to compensate. This allows the engine to maintain peak efficiency from startup, rather than gradually working towards the optimum mixture. The ECU stores Lambda values from previous journeys to make these adjustments.

9.2 Applications of Adaptations

Adaptations apply to various systems, including hydraulic systems and engine components. As components wear, the ECU adjusts solenoid activation timing and throttle flap opening angles to maintain optimal performance.

10. Understanding and Addressing Common ECU-Related Faults

Diagnosing ECU issues effectively requires a clear understanding of common problems and their symptoms. Here’s a breakdown of several frequently encountered fault conditions and how to approach them.

10.1 How to Diagnose a Faulty ECU with No Communications

When an ECU fails to communicate, diagnosing the issue can be challenging. This section outlines steps to identify and address communication problems.

Step 1: Initial Checks

Begin by confirming the basics, verify the battery voltage and check for any blown fuses related to the ECU.

Step 2: Scan Tool Verification

Ensure your scan tool is properly connected and compatible with the vehicle. Try using the scan tool on other modules within the vehicle to confirm it’s functioning correctly.

Step 3: Wiring Inspection

Inspect the wiring harness leading to the ECU for damage, corrosion, or loose connections. Pay close attention to the ground connections, as a poor ground can cause communication issues.

Step 4: ECU Power Supply

Use a multimeter to check if the ECU is receiving power and ground. Refer to the vehicle’s wiring diagram to identify the correct pins.

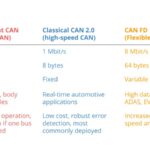

Step 5: CAN Bus Diagnostics

If the ECU communicates via CAN bus, use an oscilloscope to check the CAN high and CAN low signals. Look for proper voltage levels and signal patterns.

Step 6: ECU Replacement (Last Resort)

If all other steps fail, the ECU itself may be faulty. Before replacing it, ensure that you have ruled out all other possibilities. After replacement, the new ECU may require programming to match the vehicle’s specific configuration.

10.2 Dreaded P0606 Fault Code – Is It Really Caused by Your ECU?

The P0606 code indicates an internal control module processor error. However, it’s essential to verify the cause before replacing the ECU.

Step 1: Code Verification

Clear the P0606 code and perform a test drive to see if it returns. Sometimes, this code can appear due to transient issues.

Step 2: Wiring and Connections

Inspect all wiring and connectors leading to the ECU. Look for signs of corrosion, damage, or loose connections. Repair or replace any faulty wiring.

Step 3: Power and Ground

Check the ECU’s power and ground connections using a multimeter. Ensure they are within the specified voltage range.

Step 4: Sensor Interference

Disconnect any aftermarket accessories or modifications that could interfere with the ECU’s operation.

Step 5: ECU Testing

If the above steps don’t resolve the issue, perform advanced ECU testing.

Step 6: ECU Replacement and Programming

If the ECU is indeed faulty, replace it and program it to match the vehicle’s specifications. This step often requires specialized tools and expertise.

10.3 Bad Camshaft Position Sensor Symptoms – And How To FIX!

A faulty camshaft position sensor can cause numerous engine performance issues. Here’s how to diagnose and fix it.

Step 1: Symptoms Identification

Common symptoms include:

- Engine stalling or misfiring

- Difficulty starting

- Check engine light with codes such as P0340, P0341, etc.

- Poor fuel economy

Step 2: Code Reading

Use a scan tool to read and record any fault codes related to the camshaft position sensor.

Step 3: Visual Inspection

Inspect the sensor and its wiring for any visible damage, such as cracks, breaks, or corrosion.

Step 4: Sensor Testing

- Resistance Test: Use a multimeter to measure the resistance of the sensor. Compare the reading to the manufacturer’s specifications.

- Voltage Test: With the ignition on, check the voltage at the sensor connector. Ensure it matches the specified voltage.

- Signal Test: Use an oscilloscope to check the sensor’s signal pattern. Look for a clean, consistent signal.

Step 5: Sensor Replacement

If the sensor fails any of the tests, replace it with a new one. Ensure the new sensor is properly installed and torqued to the correct specification.

Step 6: Code Clearing and Testing

Clear the fault codes and perform a test drive to ensure the issue is resolved. Monitor the engine for any recurring symptoms.

10.4 Faulty Crankshaft Position Sensor? – How to Test and Fix!

The crankshaft position sensor is vital for engine timing. Here’s how to diagnose and fix issues with it.

Step 1: Symptoms Identification

Common symptoms include:

- Engine won’t start

- Engine stalls shortly after starting

- Check engine light with codes such as P0335, P0336, etc.

- Engine misfires

Step 2: Code Reading

Use a scan tool to read and record any fault codes related to the crankshaft position sensor.

Step 3: Visual Inspection

Inspect the sensor and its wiring for any visible damage, such as cracks, breaks, or corrosion.

Step 4: Sensor Testing

- Resistance Test: Use a multimeter to measure the resistance of the sensor. Compare the reading to the manufacturer’s specifications.

- Voltage Test: With the ignition on, check the voltage at the sensor connector. Ensure it matches the specified voltage.

- Signal Test: Use an oscilloscope to check the sensor’s signal pattern. Look for a clean, consistent signal.

Step 5: Sensor Replacement

If the sensor fails any of the tests, replace it with a new one. Ensure the new sensor is properly installed and torqued to the correct specification.

Step 6: Code Clearing and Testing

Clear the fault codes and perform a test drive to ensure the issue is resolved. Monitor the engine for any recurring symptoms.

These detailed diagnostic steps and procedures aim to provide technicians with a comprehensive guide to addressing common ECU-related faults efficiently and accurately.

11. The Timeline of the ECU: From Simple Controls to Complex Management

The ECU has evolved significantly over the decades, from controlling simple solenoids to managing complex engine systems.

11.1 1970s: Early ECUs

ECUs began by controlling solenoids on carburetors, improving their effectiveness and managing mixture at idle speeds.

11.2 1980s: Fuel Injection Era

With the introduction of fuel injection, the ECU became responsible for fuel and ignition management in gasoline engines. Closed-loop Lambda control was included, marking a new era in engine efficiency.

11.3 1990s: Diesel and Security Advancements

The ECU expanded into diesel engines and began handling vehicle security functions, contributing to the success of turbodiesel engines.

11.4 2000s: Drive-by-Wire and Emission Systems

The adoption of drive-by-wire throttle control, turbocharger control, and numerous emission systems placed more functions under the ECU’s control.

11.5 2010s and Beyond: Comprehensive Vehicle Management

Today, the ECU manages combustion, throttle opening, cooling systems, and emission systems. It integrates with a network of other electronic control units, supporting hybrid systems and driving assistance features. Modern ECUs can have over a hundred inputs and outputs.

12. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN?

At CAR-DIAGNOSTIC-TOOL.EDU.VN, we are dedicated to providing automotive technicians and garage owners with the tools, knowledge, and support needed to excel in today’s automotive landscape.

12.1 Comprehensive Diagnostic Tools

Our diagnostic tools are designed to provide accurate and reliable readings, enabling you to diagnose and repair vehicles efficiently. We offer a range of tools to suit different needs and budgets, ensuring you have the right equipment for the job.

12.2 Detailed Repair Guides

Our repair guides offer step-by-step instructions for diagnosing and repairing various automotive issues, including ECU-related problems. These guides are written by experienced technicians and are regularly updated to reflect the latest industry best practices.

12.3 Remote Support

We offer remote support to assist you with complex diagnostic and repair challenges. Our team of expert technicians is available to provide guidance and support, helping you resolve issues quickly and effectively. Contact us via Whatsapp: +1 (641) 206-8880

12.4 Technician Training

Our technician training programs are designed to enhance your skills and knowledge, keeping you up-to-date with the latest automotive technologies. We offer a range of courses covering various topics, including ECU diagnostics, advanced engine management, and electric vehicle repair.

13. Frequently Asked Questions (FAQs) About ECUs

Here are some common questions about ECUs to help you better understand their function and importance:

13.1 What is the main function of an ECU?

The main function of an ECU is to control and manage various electronic systems within a vehicle, including fuel injection, ignition timing, and emission control.

13.2 How do I know if my ECU is faulty?

Signs of a faulty ECU can include the check engine light, poor engine performance, difficulty starting, and stalling. Diagnostic tools can help confirm ECU issues.

13.3 Can I repair an ECU myself?

Repairing an ECU typically requires specialized knowledge and equipment. It’s often best to consult a professional technician.

13.4 What is the difference between an ECU, ECM, and PCM?

An ECU (Electronic Control Unit) is a general term for any electronic control module. An ECM (Engine Control Module) specifically manages the engine, while a PCM (Powertrain Control Module) controls both the engine and transmission.

13.5 How often should I have my ECU checked?

It’s a good practice to have your ECU checked during routine maintenance or if you notice any performance issues with your vehicle.

13.6 Can the ECU be reprogrammed or remapped?

Yes, the ECU can be reprogrammed or remapped to optimize engine performance, improve fuel efficiency, or customize various settings. However, this should be done by a qualified professional.

13.7 What is the role of sensors in ECU operation?

Sensors provide the ECU with real-time data about various engine parameters, such as temperature, pressure, and airflow. This data allows the ECU to make precise adjustments to optimize engine performance.

13.8 How does the ECU affect fuel efficiency?

The ECU plays a crucial role in optimizing fuel efficiency by precisely controlling fuel injection and air-fuel mixture. Efficient ECU operation can lead to significant fuel savings.

13.9 What is the CAN bus, and how does it relate to the ECU?

The CAN (Controller Area Network) bus is a communication network that allows various electronic modules within a vehicle to communicate with each other. The ECU uses the CAN bus to exchange data with other modules, enabling coordinated control of various systems.

13.10 Where can I find reliable ECU diagnostic tools and repair guides?

CAR-DIAGNOSTIC-TOOL.EDU.VN offers a range of reliable diagnostic tools, detailed repair guides, and expert support to help you diagnose and resolve ECU-related issues effectively.

14. Conclusion: Mastering Automotive Diagnostics with CAR-DIAGNOSTIC-TOOL.EDU.VN

Understanding what are ECUs and how they operate is crucial for effective automotive diagnostics and repair. At CAR-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the resources and support you need to master these skills and stay ahead in the automotive industry.

14.1 Take the Next Step: Contact Us Today

Ready to enhance your diagnostic skills and improve your repair efficiency? Contact us today to learn more about our diagnostic tools, repair guides, technician training programs, and remote support services.

Office Address: 1100 Congress Ave, Austin, TX 78701, United States

WhatsApp: +1 (641) 206-8880

Website: CAR-DIAGNOSTIC-TOOL.EDU.VN

Don’t let automotive challenges slow you down. With CAR-DIAGNOSTIC-TOOL.EDU.VN, you have a reliable partner to help you succeed in every repair. Reach out today, and let us help you elevate your expertise and grow your business.