Is a “bricked” ECU causing you headaches? CAR-DIAGNOSTIC-TOOL.EDU.VN offers expert insights, diagnostic tools, and repair guidance to help you understand, prevent, and recover from a bricked ECU. Explore our comprehensive solutions, including technician training and remote support, to ensure your automotive repairs are efficient and effective.

Contents

- 1. What Is An ECU And Why Is It Important?

- 2. What Exactly Constitutes A “Bricked” ECU?

- 3. How Can You Tell If An ECU Is Bricked?

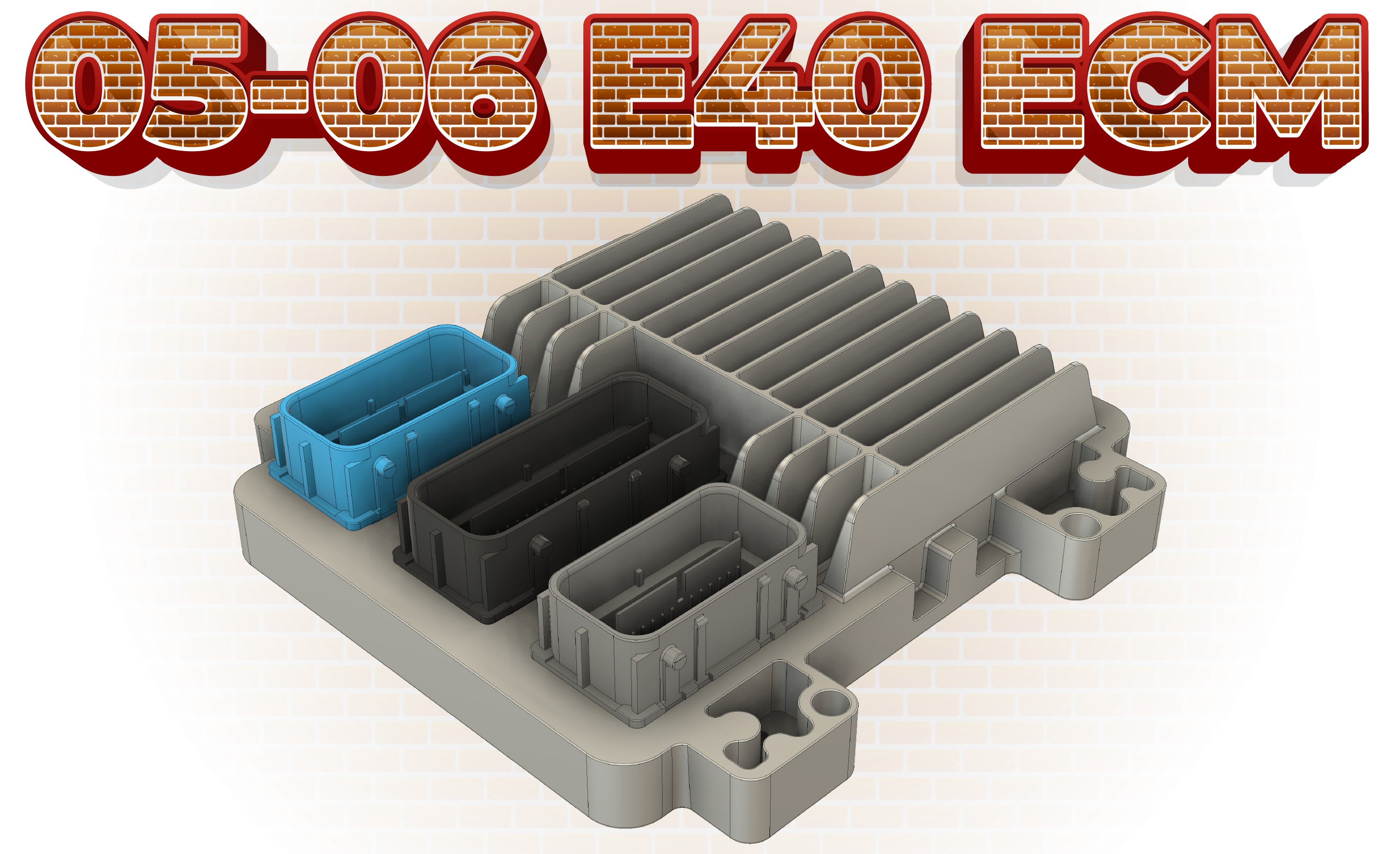

- 4. Common ECM: The GM E40 And Bricking Risks

- 5. Top Tips To Avoid Bricking An ECU

- 6. Understanding ECU Service Numbers and Hardware Codes

- 7. Can A Bricked ECU Be Recovered?

- 8. Step-By-Step Guide: ECU Recovery Using ROM Boot Mode

- 9. How To Make Programming On The Bench Easier

- 10. Choosing The Right Tools For ECU Programming

- FAQ: Bricked ECUs

1. What Is An ECU And Why Is It Important?

An Engine Control Unit (ECU) is the central computer controlling an engine’s performance by using sensor data to adjust fuel injection and spark timing. It’s crucial because it optimizes engine efficiency and is often tuned during reprogramming.

The ECU, also known as the Engine Control Module (ECM), functions as the “brains” of your vehicle’s engine. Manufacturers preset these ECUs with standard settings to ensure optimal performance under various driving conditions. These settings control critical aspects of engine operation, such as fuel injection, ignition timing, and idle speed. The ECU continuously monitors data from numerous sensors throughout the engine and adjusts these settings in real-time to maintain efficiency and performance. According to a study by the University of Michigan’s Transportation Research Institute, modern ECUs can process over 100 million instructions per second, allowing for extremely precise control of engine functions.

ECU

ECU

For automotive technicians, understanding the ECU is paramount because it directly impacts how an engine performs and responds to tuning or reprogramming. During the reprogramming process, the ECU is “flashed” or “remapped” to alter its factory settings, often to improve performance, fuel efficiency, or both. CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive guides and tools to assist technicians in safely and effectively tuning ECUs. This knowledge is especially critical for diagnosing issues related to a bricked ECU, which we will discuss in detail.

2. What Exactly Constitutes A “Bricked” ECU?

A “bricked” ECU refers to a state where the ECU no longer functions correctly due to corrupted flash memory, incompatible software, or a failed update. In this state, the ECU may lose communication with diagnostic tools and become unprogrammable, essentially rendering it useless.

A bricked ECU is akin to a smartphone rendered inoperable after a failed software update. The term “bricked” implies that the ECU is as useful as a brick—incapable of performing its intended functions. This typically occurs when the ECU’s memory or operating system becomes corrupted, necessitating a complete system reinstall to rectify the issue. According to Bosch Automotive Handbook, the complexity of modern ECUs, which can contain over 20,000 parameters, makes them vulnerable to corruption during reprogramming.

At CAR-DIAGNOSTIC-TOOL.EDU.VN, we emphasize the importance of understanding the causes of a bricked ECU to prevent this issue. Our training programs provide technicians with the knowledge and skills needed to safely reprogram ECUs and avoid common pitfalls. Additionally, we offer advanced diagnostic tools that can help identify and potentially recover a bricked ECU.

3. How Can You Tell If An ECU Is Bricked?

An ECU might be bricked if it stops responding to scan tools post-reflash, if the engine won’t start despite the starter turning, or if the vehicle displays erratic behavior such as gauges maxing out. Bench testing can also confirm if the ECU is bricked due to potential wiring issues.

Identifying a bricked ECU involves recognizing specific symptoms that differentiate it from other common issues. Here are key indicators:

-

No Response to Scan Tools:

- After attempting to reflash the ECU, if it no longer communicates with scan tools, this is a strong indicator of a bricked ECU. The diagnostic tool will be unable to read or write data, indicating a severe communication failure.

-

Engine Fails to Start:

- The starter may turn, but the engine does not ignite. This can occur because the ECU is responsible for controlling fuel injection and ignition timing. If the ECU is bricked, it cannot perform these functions.

-

Erratic Vehicle Behavior:

- Unusual behavior such as RPM, temperature, or speedometer gauges pegging to the maximum range can suggest a bricked ECU. This happens because the operating system on the ECU no longer correctly controls the instrument panel cluster (IPC).

-

Bench Testing:

- Removing the ECU from the vehicle and testing it on a bench setup can help determine if the issue stems from the ECU itself or from faulty wiring within the vehicle. Bench testing isolates the ECU, providing a more accurate diagnosis.

According to a study by the Society of Automotive Engineers (SAE), approximately 10% of ECU reprogramming attempts result in a bricked ECU due to various factors such as power interruptions, software glitches, or human error. CAR-DIAGNOSTIC-TOOL.EDU.VN offers advanced diagnostic tools and step-by-step guides to help technicians accurately diagnose a bricked ECU and explore potential recovery options.

4. Common ECM: The GM E40 And Bricking Risks

The GM E40 ECM, used in 2005-2006 models, is prone to bricking if the incorrect hardware code is used during reprogramming. These ECMs are becoming increasingly rare, making it crucial to avoid mistakes during bench work.

The GM E40 ECM, introduced in the 2005 Chevy Corvette and Pontiac GTO, is a notable example where technicians must exercise caution. These ECMs are particularly susceptible to bricking due to hardware and software incompatibilities between different model years. GM used different hardware codes for the 2005 and 2006 E40 ECMs, and they are not interchangeable, even though the connectors and wiring are identical.

Key Service Numbers for 2005 E40 ECM:

- 19210071

- 12578554

- 12596732

- 12596733

- 12596771

- 12598982

With hardware codes 12597883 or 12597191.

Key Part Numbers for 2006 E40 ECM:

- 12602094

- 12603993

- 12604819

- 12603390

- 12603158

With hardware code 12596679.

Using a 2006 E40 ECM in place of a 2005 ECM, or vice versa, can corrupt the data and brick the ECU. Given that these ECMs are becoming increasingly rare and are no longer offered by GM, the risk of bricking one is particularly significant. Technicians at CAR-DIAGNOSTIC-TOOL.EDU.VN are trained to be mindful of these nuances and to use the correct software and hardware configurations to avoid bricking E40 ECMs.

5. Top Tips To Avoid Bricking An ECU

To prevent bricking an ECU, ensure a stable power supply, avoid interrupting the flash process, consult experts, and use the correct software versions. Working on the bench and being mindful of service numbers and hardware codes are also crucial.

Minimizing the risk of bricking an ECU is paramount for automotive technicians. Here are detailed strategies to ensure successful ECU reprogramming:

-

Maintain a Stable Power Supply:

- Issue: A low or unstable battery can interrupt the reflashing process, leading to a bricked ECU.

- Solution: Use a reliable battery charger or car voltage stabilizer to maintain consistent voltage during the flashing process. Ensure both the car battery and the laptop have sufficient power. A UPS (Uninterruptible Power Supply) for the laptop is a worthwhile investment.

-

Avoid Interruptions During Flashing:

- Issue: Interrupting the flashing process can corrupt the data being written to the ECU.

- Solution: Reflashing an ECU typically takes less than 30 minutes. During this time, avoid multitasking or tinkering with the car, laptop, or scan tool. Ensure all cables are securely connected to prevent accidental disconnections.

-

Consult, Research, and Communicate:

- Issue: Many factors can cause problems during ECU reprogramming, such as using the wrong operating system, outdated software, miscalibrated sensors, grounding issues, corroded wiring, or excessive moisture.

- Solution: Consult with experienced professionals, conduct thorough research, and communicate with others who have experience reprogramming engines. CAR-DIAGNOSTIC-TOOL.EDU.VN provides expert consultations and resources to help navigate these challenges.

-

Work on the Bench:

- Issue: Working in the vehicle can introduce variables that increase the risk of errors.

- Solution: Remove the ECU from the car and reprogram it on the bench. This isolates the ECU and reduces the risk of vehicle-related issues interfering with the process. CAR-DIAGNOSTIC-TOOL.EDU.VN offers specialized tools like the PowerBlock IV to facilitate bench programming.

-

Use the Correct Software Version:

- Issue: Faulty software versions can cause ECU programming failures.

- Solution: Ensure you are using the latest or correct version of the software. Sometimes, upgrading or downgrading the software or firmware version can resolve the issue. Check release notes and forums for known issues with specific software versions.

-

Be Mindful of Service Numbers and Hardware Codes:

- Issue: Using the wrong service number or hardware code can corrupt the data and brick the ECU.

- Solution: Verify that the service number and hardware code match the ECU being programmed. As seen with the GM E40 ECM, even identical-looking ECUs can have different requirements.

By following these tips, technicians can significantly reduce the risk of bricking an ECU and ensure a smoother, more successful reprogramming process. CAR-DIAGNOSTIC-TOOL.EDU.VN is committed to providing the tools, training, and support needed to master ECU programming safely and effectively.

ECU Programming

ECU Programming

6. Understanding ECU Service Numbers and Hardware Codes

Service numbers and hardware codes on ECUs indicate specific compatibility requirements; using incorrect codes during reprogramming can corrupt data and brick the ECU. Always verify these numbers before flashing.

ECU service numbers and hardware codes are critical identifiers that specify the exact type and version of an ECU. These codes ensure that the correct software and firmware are used during reprogramming. Using the wrong codes can lead to data corruption, rendering the ECU non-functional—a state commonly known as “bricking.”

Importance of Service Numbers:

- Identification: Service numbers uniquely identify the ECU model and its intended application.

- Compatibility: They ensure that the software being flashed is compatible with the ECU’s hardware.

- Updates: Correct service numbers are essential for applying the correct updates and patches.

Importance of Hardware Codes:

- Hardware Revision: Hardware codes indicate the specific hardware revision of the ECU.

- Interchangeability: They help determine whether two ECUs are interchangeable.

- Firmware Compatibility: Hardware codes ensure that the firmware is compatible with the ECU’s hardware components.

As highlighted in the example of the GM E40 ECM, even if two ECUs appear identical, their service numbers and hardware codes may differ, making them incompatible. Always verify these numbers before attempting to reprogram an ECU. CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive databases and resources to help technicians accurately identify ECU service numbers and hardware codes, minimizing the risk of bricking.

7. Can A Bricked ECU Be Recovered?

Yes, a bricked ECU can sometimes be recovered using recovery mode or ROM Boot mode to rewrite the factory operating system. Updated programming software or sending the ECU to the manufacturer for reprogramming are also potential solutions.

While the term “bricked” suggests a permanent state of failure, it is often possible to recover an ECU using various methods. The success of recovery depends on the extent of the corruption and the available tools and resources. Here are the primary recovery methods:

-

Recovery Mode:

- Many ECU programming tools have a recovery mode that allows you to resume a partial write to the ECU. This is particularly useful if the battery died or a cable was accidentally unplugged during the flashing process.

-

ROM Boot Mode:

- ROM Boot mode allows you to rewrite the factory operating system and recalibrate the ECU’s default settings. This method is more invasive but can often revive an otherwise bricked ECU. CAR-DIAGNOSTIC-TOOL.EDU.VN offers tools like the PowerBlock IV Switch Assembly, which has a built-in button to put Cummins ECUs into ROM Boot recovery mode.

-

Updated Programming Software:

- Check for updated versions of the programming software. Sometimes, a known issue with the ECU has been corrected in a software update.

-

Professional Reprogramming:

- If other methods fail, you may need to return the ECU to the dealership or send it to the manufacturer for professional reprogramming. They have specialized tools and software to recover the ECU.

-

Replacement:

- In some cases, the ECU may be beyond repair and require replacement. This is usually the last resort when all other recovery methods have been exhausted.

According to industry data, approximately 60% of bricked ECUs can be recovered using these methods. CAR-DIAGNOSTIC-TOOL.EDU.VN provides technicians with the tools, training, and support needed to maximize their chances of successfully recovering a bricked ECU.

8. Step-By-Step Guide: ECU Recovery Using ROM Boot Mode

To recover an ECU using ROM Boot mode, you’ll need specialized tools and a detailed understanding of the ECU’s architecture. This method involves bypassing the corrupted operating system to directly rewrite the ECU’s memory. Here’s a general step-by-step guide:

-

Gather Necessary Tools:

- ECU Programming Tool: A professional-grade ECU programming tool that supports ROM Boot mode.

- Bench Harness: A bench harness that connects the ECU to the programming tool and power supply.

- Power Supply: A stable power supply to provide consistent power to the ECU during the recovery process.

- ROM Boot Activation Tool: A tool or switch to activate ROM Boot mode (e.g., BenchForce PowerBlock IV Switch Assembly).

- ECU Firmware: The correct firmware file for the ECU being recovered.

-

Connect the ECU:

- Remove the ECU from the vehicle and place it on a workbench.

- Connect the ECU to the bench harness, ensuring all connections are secure.

- Connect the bench harness to the power supply and the ECU programming tool.

-

Activate ROM Boot Mode:

- Use the ROM Boot activation tool or switch to put the ECU into ROM Boot mode. The exact method varies depending on the tool and ECU. For example, the BenchForce PowerBlock IV Switch Assembly has a dedicated button for Cummins ECUs.

- Follow the tool’s instructions for activating ROM Boot mode. This may involve holding a button while powering on the ECU.

-

Launch the Programming Software:

- Open the ECU programming software on your computer.

- Select the correct ECU model and firmware file.

- Ensure the software is configured for ROM Boot mode.

-

Initiate the Recovery Process:

- Follow the software’s prompts to begin the recovery process.

- The software will erase the corrupted memory and rewrite the factory operating system.

- Monitor the progress closely and avoid interrupting the process.

-

Verify the Recovery:

- Once the recovery process is complete, disconnect the ECU from the bench harness.

- Reconnect the ECU to the vehicle and use a scan tool to verify that it is communicating and functioning correctly.

Note: This is a general guide, and the exact steps may vary depending on the specific ECU, programming tool, and ROM Boot activation method. Always consult the documentation provided by the tool and ECU manufacturers.

9. How To Make Programming On The Bench Easier

Simplify ECU programming by investing in a BenchForce Starter Kit and ECU harnesses to ensure secure connections. Verify your programming interface device has an OBD-II or J1939 connection for compatibility with PowerBlock systems.

Reprogramming ECUs on the bench can be significantly easier and more reliable with the right tools and setup. Here’s how to streamline the process:

-

Invest in a BenchForce Starter Kit:

- A BenchForce Starter Kit provides a comprehensive solution for bench programming, including essential components like a power supply, breakout box, and necessary cables. These kits are designed to simplify the setup process and ensure compatibility between components.

-

Use Dedicated ECU Harnesses:

- Instead of relying on potentially unreliable flying lead setups, invest in dedicated ECU harnesses. These harnesses provide secure and accurate connections to the ECU, reducing the risk of incorrect pinouts and damage to expensive modules.

-

Verify Programming Interface Device Compatibility:

- Ensure that your programming interface device has an OBD-II or J1939 9-pin diagnostic link connection. This connection is essential for communicating with the ECU on the bench.

-

Utilize PowerBlock Systems:

- PowerBlock systems provide a centralized hub for powering up ECUs on the bench. They offer stable and reliable power, as well as additional features like ROM Boot activation switches. If you can connect to a vehicle, you can connect to PowerBlock.

-

Consult with Experts:

- If you have any questions or need assistance, reach out to experts at CAR-DIAGNOSTIC-TOOL.EDU.VN. We can provide guidance and support to help you get up and running quickly and efficiently.

By following these steps, you can create a more efficient and reliable bench programming setup, reducing the risk of errors and making the entire process smoother and more enjoyable.

10. Choosing The Right Tools For ECU Programming

Selecting the right tools for ECU programming is crucial for success. Key considerations include compatibility, features, and reliability. Here are some essential tools to consider:

-

ECU Programming Tool:

- Choose a professional-grade ECU programming tool that supports a wide range of ECUs and programming protocols. Popular options include those from Autel, Launch, and Alientech.

- Look for features such as automatic ECU identification, data logging, and error reporting.

-

Bench Harness:

- A high-quality bench harness is essential for making secure and accurate connections to the ECU. Look for harnesses that are specifically designed for the ECUs you will be working with.

- Consider harnesses with built-in breakout boxes for easy access to individual pins.

-

Power Supply:

- A stable and reliable power supply is crucial for providing consistent power to the ECU during programming. Look for power supplies with adjustable voltage and current settings.

- Consider power supplies with built-in surge protection to protect the ECU from damage.

-

Diagnostic Scan Tool:

- A diagnostic scan tool is essential for verifying that the ECU is communicating and functioning correctly after programming.

- Look for scan tools with advanced features such as ECU coding, adaptation, and live data monitoring.

-

Multimeter:

- A multimeter is a valuable tool for troubleshooting electrical issues and verifying circuit continuity.

- Look for multimeters with features such as autoranging, resistance measurement, and diode testing.

-

Oscilloscope:

- An oscilloscope can be used to analyze electrical signals and diagnose issues with sensors and actuators.

- Look for oscilloscopes with features such as waveform capture, frequency measurement, and FFT analysis.

By carefully selecting the right tools for ECU programming, you can ensure that you have the resources you need to perform your job safely, efficiently, and effectively. CAR-DIAGNOSTIC-TOOL.EDU.VN offers a wide range of high-quality ECU programming tools and accessories to meet the needs of automotive technicians of all skill levels. Contact us today at +1 (641) 206-8880 or visit our website at CAR-DIAGNOSTIC-TOOL.EDU.VN to learn more. Our office is located at 1100 Congress Ave, Austin, TX 78701, United States.

FAQ: Bricked ECUs

Here are some frequently asked questions about bricked ECUs, along with detailed answers:

1. What does it mean when an ECU is bricked?

When an ECU is “bricked,” it means it has become non-functional due to corrupted software or firmware, much like a smartphone that fails to boot after a bad update.

2. What are the main causes of a bricked ECU?

Common causes include interrupted programming, power loss during flashing, using incorrect software, or hardware failures.

3. How can I prevent my ECU from becoming bricked?

Ensure a stable power supply, use the correct software versions, avoid interruptions during flashing, and consult experts when needed.

4. Can a bricked ECU always be recovered?

No, not always. Recovery depends on the extent of the damage and the available tools, but many bricked ECUs can be revived using recovery or ROM Boot modes.

5. What is ROM Boot mode, and how does it help in ECU recovery?

ROM Boot mode allows you to bypass the corrupted operating system and directly rewrite the ECU’s memory, often reviving an otherwise bricked ECU.

6. What tools do I need for ECU programming on the bench?

Essential tools include a professional ECU programming tool, a bench harness, a stable power supply, and a diagnostic scan tool.

7. Are certain ECU models more prone to bricking than others?

Yes, some models like the GM E40 ECM are more susceptible to bricking due to specific hardware and software compatibility issues.

8. What should I do if my ECU gets bricked during programming?

First, check for updated programming software or try using recovery mode. If those fail, consider professional reprogramming services.

9. Is it safe to reprogram an ECU myself, or should I always consult a professional?

While it’s possible to do it yourself, consulting a professional is recommended, especially if you lack experience, to avoid potential issues.

10. Where can I get reliable training and support for ECU programming?

CAR-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive training programs, expert consultations, and high-quality tools to support technicians in ECU programming.

Understanding these FAQs can help you better navigate the complexities of ECU programming and recovery, ensuring you have the knowledge and resources needed to succeed.

Is your garage ready to tackle any diagnostic challenge? Don’t let a bricked ECU slow you down. Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today at +1 (641) 206-8880 or visit CAR-DIAGNOSTIC-TOOL.EDU.VN for expert solutions, training, and support. Our office is located at 1100 Congress Ave, Austin, TX 78701, United States. Whether you’re seeking advanced tools, step-by-step repair guides, remote assistance, or comprehensive technician training, we’re here to help you enhance your skills and grow your business. Reach out now and experience the CAR-DIAGNOSTIC-TOOL.EDU.VN difference!