When Is Ecu Shred Days? CAR-DIAGNOSTIC-TOOL.EDU.VN is here to guide you through understanding ECU shred days, along with providing comprehensive automotive diagnostic tools, repair guidance, and remote support. Learn how to effectively manage automotive waste, enhance your repair skills, and access expert assistance, including technician training and remote support.

Contents

- 1. Understanding ECU Shred Days and Automotive Recycling

- 1.1 Defining ECU Shred Days

- 1.2 The Automotive Recycling Process

- 1.2.1 Dismantling and Sorting

- 1.2.2 Material Processing

- 1.2.3 Environmental Benefits

- 1.3 Types of Automotive Waste Eligible for Recycling

- 2. Why Automotive Recycling and ECU Shred Days Matter

- 2.1 Environmental Benefits

- 2.2 Economic Advantages

- 2.3 Regulatory Compliance

- 3. Key Components Recycled During ECU Shred Days

- 3.1 Electronic Control Units (ECUs)

- 3.1.1 Composition of ECUs

- 3.1.2 Recycling Process for ECUs

- 3.1.3 Benefits of Recycling ECUs

- 3.2 Batteries

- 3.2.1 Types of Automotive Batteries

- 3.2.2 Recycling Process for Batteries

- 3.2.3 Benefits of Recycling Batteries

- 3.3 Metals

- 3.3.1 Types of Metals Recycled

- 3.3.2 Recycling Process for Metals

- 3.3.3 Benefits of Recycling Metals

- 3.4 Plastics

- 3.4.1 Types of Plastics Recycled

- 3.4.2 Recycling Process for Plastics

- 3.4.3 Benefits of Recycling Plastics

- 3.5 Fluids

- 3.5.1 Types of Fluids Recycled

- 3.5.2 Recycling Process for Fluids

- 3.5.3 Benefits of Recycling Fluids

- 4. Step-by-Step Guide to Participating in ECU Shred Days

- 4.1 Identifying Dates and Locations

- 4.2 Preparing Materials for Recycling

- 4.3 Dropping Off Items at Designated Locations

- 4.4 Following Up on the Recycling Process

- 5. Maximizing Efficiency in Your Automotive Repair Shop

- 5.1 Utilizing Advanced Diagnostic Tools

- 5.2 Implementing Efficient Repair Processes

- 5.3 Managing Automotive Waste Effectively

- 5.4 Investing in Technician Training

- 6. Advanced Diagnostic Tools for ECU Recycling

- 6.1 ECU Programmers

- 6.1.1 Features of ECU Programmers

- 6.1.2 Benefits of Using ECU Programmers

- 6.2 Diagnostic Scanners

- 6.2.1 Features of Diagnostic Scanners

- 6.2.2 Benefits of Using Diagnostic Scanners

- 6.3 Multimeters

- 6.3.1 Features of Multimeters

- 6.3.2 Benefits of Using Multimeters

- 6.4 Soldering Stations

- 6.4.1 Features of Soldering Stations

- 6.4.2 Benefits of Using Soldering Stations

- 7. Remote Support for Complex ECU Recycling Issues

- 7.1 Diagnostic Assistance

- 7.1.1 Expert Guidance

- 7.1.2 Remote Diagnostics

- 7.1.3 Troubleshooting Support

- 7.2 Software Support

- 7.2.1 Software Updates

- 7.2.2 Bug Fixes

- 7.2.3 Reprogramming Assistance

- 7.3 Component Recovery Guidance

- 7.3.1 Safe Removal Techniques

- 7.3.2 Best Practices

- 7.3.3 Environmental Considerations

- 8. Training Programs for Automotive Technicians on ECU Recycling

- 8.1 Diagnostic Techniques

- 8.1.1 Advanced Diagnostic Tools

- 8.1.2 Troubleshooting Strategies

- 8.1.3 Real-World Case Studies

- 8.2 Component Recovery

- 8.2.1 Safe Removal Practices

- 8.2.2 Best Practices

- 8.2.3 Environmental Considerations

- 8.3 Environmental Compliance

- 8.3.1 Environmental Regulations

- 8.3.2 Waste Management

- 8.3.3 Sustainability Practices

- 9. Benefits of Using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU Recycling

- 9.1 Access to Advanced Tools

- 9.1.1 High-Quality Equipment

- 9.1.2 Latest Technology

- 9.1.3 Tool Selection

- 9.2 Expert Support

- 9.2.1 Remote Assistance

- 9.2.2 Troubleshooting Tips

- 9.2.3 Technical Expertise

- 9.3 Comprehensive Training

- 9.3.1 Online Courses

- 9.3.2 Hands-On Workshops

- 9.3.3 Certification Programs

- 9.4 Cost-Effective Solutions

- 9.4.1 Competitive Pricing

- 9.4.2 Time Savings

- 9.4.3 Reduced Waste

- 10. Frequently Asked Questions About ECU Shred Days

- 10.1 When and Where Are ECU Shred Days Held?

- 10.2 What Types of Materials Are Accepted at ECU Shred Days?

- 10.3 How Should I Prepare My Materials for ECU Shred Days?

- 10.4 What Happens to the Materials Collected at ECU Shred Days?

- 10.5 What Are the Environmental Benefits of Participating in ECU Shred Days?

- 10.6 Are There Any Costs Associated with Participating in ECU Shred Days?

Table of Contents

- Understanding ECU Shred Days and Automotive Recycling

- Why Automotive Recycling and ECU Shred Days Matter

- Key Components Recycled During ECU Shred Days

- Step-by-Step Guide to Participating in ECU Shred Days

- Maximizing Efficiency in Your Automotive Repair Shop

- Advanced Diagnostic Tools for ECU Recycling

- Remote Support for Complex ECU Recycling Issues

- Training Programs for Automotive Technicians on ECU Recycling

- Benefits of Using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU Recycling

- Frequently Asked Questions About ECU Shred Days

1. Understanding ECU Shred Days and Automotive Recycling

When is ECU shred days? ECU shred days generally refer to specific periods or events organized to collect and recycle electronic control units (ECUs) and other electronic waste from vehicles, promoting sustainability. Understanding ECU shred days involves knowing the timing, process, and importance of recycling automotive components for environmental and economic benefits.

ECU shred days are crucial for several reasons, focusing on the proper handling and disposal of electronic components from vehicles. These events help manage electronic waste responsibly, ensuring that harmful materials are processed safely and don’t end up in landfills. According to the EPA, electronic waste is one of the fastest-growing waste streams globally, making initiatives like ECU shred days vital for environmental protection. (EPA, “Facts and Figures about Materials, Waste and Recycling,” 2023).

1.1 Defining ECU Shred Days

ECU shred days are organized events or periods dedicated to the collection and recycling of automotive electronic control units (ECUs). These events are designed to promote environmental sustainability by ensuring that electronic waste is properly managed and recycled. Understanding the purpose, timing, and process involved in ECU shred days is crucial for participation and maximizing their benefits.

The primary goal of ECU shred days is to divert electronic waste from landfills, where harmful materials can leach into the environment and cause pollution. By collecting and recycling ECUs, these events help recover valuable materials such as metals and plastics, reducing the need for new resource extraction. According to a study by the United Nations Environment Programme, recycling electronic waste can significantly reduce greenhouse gas emissions and conserve natural resources. (UNEP, “Recycling – From E-Waste to Resources,” 2015).

1.2 The Automotive Recycling Process

The automotive recycling process is a multi-stage operation that involves dismantling vehicles, sorting materials, and processing them for reuse. This process not only reduces waste but also recovers valuable resources, contributing to a circular economy. Recycling automotive components helps conserve energy, reduce pollution, and lower the environmental impact of vehicle production.

1.2.1 Dismantling and Sorting

The initial stage involves dismantling vehicles to remove reusable and recyclable parts. This includes components like engines, transmissions, and electronic control units (ECUs). The materials are then sorted into categories such as metal, plastic, and glass for further processing.

1.2.2 Material Processing

Once sorted, the materials undergo processing to prepare them for reuse. Metals are melted down and refined, plastics are shredded and pelletized, and glass is crushed and cleaned. These processed materials can then be used to manufacture new automotive parts or other products.

1.2.3 Environmental Benefits

Recycling automotive components offers significant environmental benefits. It reduces the need for raw material extraction, lowers energy consumption, and decreases greenhouse gas emissions. According to the Institute of Scrap Recycling Industries (ISRI), recycling metals saves up to 74% of the energy required to produce them from virgin ore. (ISRI, “The Economic Impact of the Recycling Industry,” 2020).

1.3 Types of Automotive Waste Eligible for Recycling

Many types of automotive waste are eligible for recycling, including metals, plastics, fluids, and electronic components. Identifying and properly sorting these materials is essential for effective recycling and waste management.

- Metals: Steel, aluminum, and copper are commonly recycled from vehicles. These metals can be melted down and reused in various industries.

- Plastics: Automotive plastics, such as bumpers and interior trim, can be recycled into new plastic products.

- Fluids: Used oil, coolant, and brake fluid can be recycled or reprocessed for further use.

- Electronic Components: ECUs, sensors, and wiring harnesses contain valuable materials that can be recovered through specialized recycling processes.

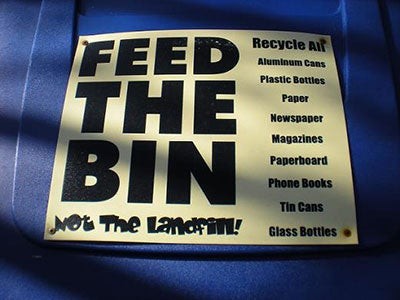

Automotive Recycling

Automotive Recycling

2. Why Automotive Recycling and ECU Shred Days Matter

Why does automotive recycling and ECU shred days matter? Automotive recycling and ECU shred days are crucial for environmental sustainability, resource conservation, and economic benefits. These initiatives reduce waste, lower pollution, and promote a circular economy, ensuring a healthier planet for future generations.

The importance of automotive recycling and ECU shred days is underscored by several key factors. First, recycling reduces the environmental impact of vehicle production by decreasing the need for raw material extraction. Second, it helps conserve energy and lower greenhouse gas emissions. Finally, it promotes economic growth by creating jobs in the recycling industry and reducing waste disposal costs. According to a report by the World Economic Forum, transitioning to a circular economy could generate trillions of dollars in economic value and create millions of jobs globally. (World Economic Forum, “Towards the Circular Economy,” 2014).

2.1 Environmental Benefits

Automotive recycling and ECU shred days offer numerous environmental benefits, including reducing pollution, conserving resources, and minimizing landfill waste. These efforts contribute to a cleaner and more sustainable environment.

- Reduced Pollution: Recycling automotive components helps reduce air and water pollution associated with mining and manufacturing processes.

- Resource Conservation: Recycling conserves natural resources by reusing materials instead of extracting new ones.

- Minimized Landfill Waste: Recycling diverts waste from landfills, reducing the environmental impact of waste disposal.

2.2 Economic Advantages

The economic advantages of automotive recycling and ECU shred days are substantial. These initiatives create jobs, reduce waste disposal costs, and generate revenue from the sale of recycled materials.

- Job Creation: The recycling industry provides employment opportunities in collection, processing, and manufacturing.

- Reduced Waste Disposal Costs: Recycling reduces the volume of waste sent to landfills, lowering disposal costs for businesses and municipalities.

- Revenue Generation: Recycled materials can be sold to manufacturers, generating revenue and offsetting recycling costs.

2.3 Regulatory Compliance

Participating in automotive recycling and ECU shred days helps ensure regulatory compliance with environmental laws and regulations. This can protect businesses from fines and legal liabilities while promoting responsible waste management practices.

- Environmental Laws: Compliance with environmental laws, such as the Resource Conservation and Recovery Act (RCRA), is essential for responsible waste management.

- Regulations: Adhering to recycling regulations ensures that automotive waste is handled properly, minimizing environmental risks.

- Legal Liabilities: Proper recycling practices can protect businesses from legal liabilities associated with improper waste disposal.

3. Key Components Recycled During ECU Shred Days

What key components are recycled during ECU shred days? Key components recycled during ECU shred days include electronic control units (ECUs), batteries, metals, plastics, and fluids. Proper recycling of these components ensures environmental safety and resource recovery.

Understanding the key components recycled during ECU shred days is essential for maximizing the benefits of these events. ECUs contain valuable materials such as gold, silver, and palladium, which can be recovered and reused. Batteries contain lead and other hazardous materials that must be properly managed to prevent environmental contamination. Metals and plastics can be recycled into new automotive parts or other products. Fluids such as oil and coolant can be reprocessed and reused. According to a study by Argonne National Laboratory, recycling automotive components can significantly reduce the environmental impact of vehicle production and disposal. (Argonne National Laboratory, “Life-Cycle Analysis of Automotive Recycling,” 2018).

3.1 Electronic Control Units (ECUs)

Electronic Control Units (ECUs) are a primary focus of ECU shred days due to their complex composition and valuable materials. Recycling ECUs involves dismantling them to recover metals, plastics, and other components.

3.1.1 Composition of ECUs

ECUs contain a variety of materials, including:

- Metals: Gold, silver, palladium, copper, and aluminum.

- Plastics: Various types of polymers used for casing and insulation.

- Electronic Components: Circuit boards, semiconductors, and capacitors.

3.1.2 Recycling Process for ECUs

The recycling process for ECUs typically involves the following steps:

- Collection: ECUs are collected from vehicles and automotive repair shops.

- Dismantling: ECUs are dismantled to separate components.

- Sorting: Materials are sorted into categories such as metals, plastics, and electronic components.

- Processing: Metals are melted down and refined, plastics are shredded and pelletized, and electronic components are processed for material recovery.

3.1.3 Benefits of Recycling ECUs

Recycling ECUs offers several benefits:

- Resource Recovery: Recovers valuable metals and materials.

- Environmental Protection: Prevents hazardous materials from entering landfills.

- Energy Conservation: Reduces the energy required to produce new electronic components.

3.2 Batteries

Batteries are another critical component recycled during ECU shred days due to their potential environmental impact. Recycling batteries involves safely processing them to recover lead, acid, and plastics.

3.2.1 Types of Automotive Batteries

Common types of automotive batteries include:

- Lead-Acid Batteries: Used in most conventional vehicles.

- Lithium-Ion Batteries: Used in hybrid and electric vehicles.

- Nickel-Metal Hydride Batteries: Used in some hybrid vehicles.

3.2.2 Recycling Process for Batteries

The recycling process for batteries typically involves the following steps:

- Collection: Batteries are collected from vehicles and automotive repair shops.

- Neutralization: Acid is neutralized to prevent environmental contamination.

- Separation: Materials are separated into lead, plastics, and other components.

- Processing: Lead is melted down and refined, plastics are shredded and pelletized, and other materials are processed for recovery.

3.2.3 Benefits of Recycling Batteries

Recycling batteries offers several benefits:

- Hazardous Waste Reduction: Prevents lead and other hazardous materials from entering landfills.

- Resource Recovery: Recovers lead, plastics, and other valuable materials.

- Environmental Protection: Reduces the environmental impact of battery production and disposal.

3.3 Metals

Metals are extensively recycled during ECU shred days due to their high value and recyclability. Recycling metals involves sorting, melting, and refining them for reuse in various industries.

3.3.1 Types of Metals Recycled

Common types of metals recycled from vehicles include:

- Steel: Used in body panels, frames, and structural components.

- Aluminum: Used in engines, transmissions, and wheels.

- Copper: Used in wiring harnesses and electrical components.

3.3.2 Recycling Process for Metals

The recycling process for metals typically involves the following steps:

- Collection: Metals are collected from vehicles and automotive repair shops.

- Sorting: Metals are sorted into categories such as steel, aluminum, and copper.

- Melting: Metals are melted down in furnaces.

- Refining: Molten metals are refined to remove impurities.

- Casting: Refined metals are cast into new products.

3.3.3 Benefits of Recycling Metals

Recycling metals offers several benefits:

- Resource Conservation: Reduces the need for raw material extraction.

- Energy Savings: Requires less energy than producing metals from virgin ore.

- Environmental Protection: Reduces air and water pollution associated with mining and manufacturing.

3.4 Plastics

Plastics are increasingly recycled during ECU shred days due to their prevalence in modern vehicles. Recycling plastics involves shredding, cleaning, and pelletizing them for reuse in new plastic products.

3.4.1 Types of Plastics Recycled

Common types of plastics recycled from vehicles include:

- Polypropylene (PP): Used in bumpers, interior trim, and battery cases.

- Acrylonitrile Butadiene Styrene (ABS): Used in dashboards and interior panels.

- Polyurethane (PU): Used in seats and foam components.

3.4.2 Recycling Process for Plastics

The recycling process for plastics typically involves the following steps:

- Collection: Plastics are collected from vehicles and automotive repair shops.

- Sorting: Plastics are sorted into categories based on resin type.

- Shredding: Plastics are shredded into small pieces.

- Cleaning: Shredded plastics are cleaned to remove contaminants.

- Pelletizing: Cleaned plastics are melted and formed into pellets for reuse.

3.4.3 Benefits of Recycling Plastics

Recycling plastics offers several benefits:

- Waste Reduction: Reduces the amount of plastic waste sent to landfills.

- Resource Conservation: Reduces the need for new plastic production.

- Energy Savings: Requires less energy than producing plastics from virgin materials.

3.5 Fluids

Fluids such as oil, coolant, and brake fluid are essential components recycled during ECU shred days to prevent environmental contamination. Recycling these fluids involves reprocessing and refining them for reuse.

3.5.1 Types of Fluids Recycled

Common types of fluids recycled from vehicles include:

- Oil: Used to lubricate engines and transmissions.

- Coolant: Used to regulate engine temperature.

- Brake Fluid: Used to transmit pressure in braking systems.

3.5.2 Recycling Process for Fluids

The recycling process for fluids typically involves the following steps:

- Collection: Fluids are collected from vehicles and automotive repair shops.

- Filtering: Fluids are filtered to remove contaminants.

- Reprocessing: Fluids are reprocessed to remove impurities.

- Refining: Reprocessed fluids are refined to meet quality standards.

- Reuse: Refined fluids are reused in automotive applications or other industries.

3.5.3 Benefits of Recycling Fluids

Recycling fluids offers several benefits:

- Environmental Protection: Prevents hazardous fluids from contaminating soil and water.

- Resource Conservation: Reduces the need for new fluid production.

- Cost Savings: Reduces the cost of purchasing new fluids.

4. Step-by-Step Guide to Participating in ECU Shred Days

How can I participate in ECU shred days? Participating in ECU shred days involves several steps: identifying the dates and locations, preparing the materials, dropping off the items, and following up on the recycling process. This ensures efficient and effective recycling.

A step-by-step guide to participating in ECU shred days ensures that individuals and businesses can contribute effectively to automotive recycling efforts. The process involves several key steps:

- Identify Dates and Locations: Find out when and where ECU shred days are being held.

- Prepare Materials: Sort and clean the automotive waste you plan to recycle.

- Drop Off Items: Take the prepared materials to the designated drop-off location during the event.

- Follow Up: Inquire about the recycling process and the impact of your contribution.

Following these steps will help maximize the benefits of ECU shred days and promote environmental sustainability. According to the National Recycling Coalition, community participation is essential for the success of recycling programs. (National Recycling Coalition, “Community Recycling Programs,” 2019).

4.1 Identifying Dates and Locations

Identifying the dates and locations of ECU shred days is the first step in participating. This information is typically available through local government websites, community organizations, and automotive industry associations.

- Local Government Websites: Check the websites of your local city and county governments for announcements and schedules.

- Community Organizations: Contact local environmental groups and recycling centers for information on ECU shred days.

- Automotive Industry Associations: Consult automotive industry associations for details on recycling events and initiatives.

4.2 Preparing Materials for Recycling

Preparing materials for recycling involves sorting and cleaning automotive waste to ensure it meets the requirements of the recycling program. This may include removing fluids, disassembling components, and separating materials by type.

- Sorting: Separate materials into categories such as metals, plastics, fluids, and electronic components.

- Cleaning: Remove any contaminants from the materials, such as dirt, grease, and oil.

- Disassembly: Disassemble components as needed to facilitate recycling.

4.3 Dropping Off Items at Designated Locations

Dropping off items at designated locations involves transporting the prepared materials to the ECU shred day event and following the instructions of the event organizers. This may include completing paperwork, unloading materials, and receiving confirmation of participation.

- Transportation: Transport the prepared materials to the designated drop-off location.

- Paperwork: Complete any required paperwork, such as registration forms or waste manifests.

- Unloading: Unload the materials at the designated drop-off point.

- Confirmation: Receive confirmation of participation, such as a receipt or certificate.

4.4 Following Up on the Recycling Process

Following up on the recycling process involves inquiring about the destination and processing of the recycled materials. This helps ensure that the materials are handled properly and that the recycling program is achieving its environmental goals.

- Inquire: Contact the event organizers or recycling center to inquire about the recycling process.

- Track: Track the progress of the recycled materials through the recycling supply chain.

- Report: Report any issues or concerns to the appropriate authorities.

5. Maximizing Efficiency in Your Automotive Repair Shop

How do I maximize efficiency in my automotive repair shop? Maximizing efficiency in your automotive repair shop involves using diagnostic tools, efficient repair processes, waste management practices, and technician training. This leads to improved productivity and profitability.

Maximizing efficiency in your automotive repair shop involves several key strategies:

- Utilizing Advanced Diagnostic Tools: Accurate diagnostics save time and reduce errors.

- Implementing Efficient Repair Processes: Streamlined processes improve workflow and reduce downtime.

- Managing Automotive Waste Effectively: Proper waste management reduces costs and ensures compliance.

- Investing in Technician Training: Skilled technicians perform repairs faster and more accurately.

Implementing these strategies can significantly improve the efficiency and profitability of your automotive repair shop. According to a study by the Automotive Management Institute (AMI), efficient shop management practices can increase profitability by up to 20%. (AMI, “Shop Management Best Practices,” 2021).

5.1 Utilizing Advanced Diagnostic Tools

Utilizing advanced diagnostic tools is crucial for accurately identifying and resolving automotive issues. These tools can save time, reduce errors, and improve customer satisfaction. CAR-DIAGNOSTIC-TOOL.EDU.VN offers a range of diagnostic tools to meet the needs of automotive repair shops.

- OBD-II Scanners: Read and clear diagnostic trouble codes (DTCs) from vehicle computers.

- Multimeters: Measure voltage, current, and resistance in electrical circuits.

- Oscilloscopes: Display electrical signals to diagnose intermittent problems.

- Scan Tools: Perform advanced diagnostics and programming functions.

5.2 Implementing Efficient Repair Processes

Implementing efficient repair processes involves streamlining workflow, organizing tools and equipment, and using standardized procedures. This can reduce downtime, improve productivity, and enhance customer service.

- Streamlined Workflow: Optimize the flow of vehicles through the repair shop to minimize bottlenecks.

- Organized Tools and Equipment: Keep tools and equipment organized and readily accessible.

- Standardized Procedures: Use standardized procedures for common repairs to ensure consistency and accuracy.

5.3 Managing Automotive Waste Effectively

Managing automotive waste effectively involves implementing proper waste management practices, such as recycling, waste segregation, and hazardous waste disposal. This can reduce costs, ensure compliance, and protect the environment.

- Recycling: Recycle automotive waste such as metals, plastics, fluids, and batteries.

- Waste Segregation: Segregate waste into categories such as recyclable, non-recyclable, and hazardous.

- Hazardous Waste Disposal: Dispose of hazardous waste according to regulatory requirements.

5.4 Investing in Technician Training

Investing in technician training is essential for keeping technicians up-to-date on the latest automotive technologies and repair techniques. This can improve their skills, increase their efficiency, and enhance the quality of their work. CAR-DIAGNOSTIC-TOOL.EDU.VN offers training programs to help automotive technicians advance their careers.

- Online Courses: Provide technicians with access to online training courses on a variety of automotive topics.

- Hands-On Workshops: Offer hands-on workshops to provide technicians with practical experience.

- Certification Programs: Help technicians earn certifications to demonstrate their expertise.

6. Advanced Diagnostic Tools for ECU Recycling

What advanced diagnostic tools are needed for ECU recycling? Advanced diagnostic tools for ECU recycling include ECU programmers, diagnostic scanners, multimeters, and soldering stations. These tools facilitate efficient and accurate ECU testing and component recovery.

Advanced diagnostic tools are essential for ECU recycling, allowing technicians to accurately test, diagnose, and recover valuable components from electronic control units. These tools facilitate efficient and environmentally responsible recycling practices.

- ECU Programmers: Enable technicians to read, write, and modify ECU software.

- Diagnostic Scanners: Provide detailed diagnostic information and fault codes.

- Multimeters: Measure voltage, current, and resistance for component testing.

- Soldering Stations: Allow for the safe removal and replacement of electronic components.

Using these tools, technicians can maximize the value of recycled ECUs while minimizing environmental impact. According to a report by the Institute for Sustainable Automotive Recycling (ISAR), advanced diagnostic tools can significantly improve the efficiency and effectiveness of ECU recycling processes. (ISAR, “Sustainable Automotive Recycling Technologies,” 2022).

6.1 ECU Programmers

ECU programmers are essential tools for reading, writing, and modifying ECU software. These tools enable technicians to diagnose software issues, reprogram ECUs, and recover valuable data.

6.1.1 Features of ECU Programmers

Key features of ECU programmers include:

- Software Compatibility: Compatibility with a wide range of ECU models and software versions.

- Data Logging: Ability to log data for analysis and troubleshooting.

- Reprogramming: Capability to reprogram ECUs with updated software.

- Security Features: Security features to prevent unauthorized access and modification.

6.1.2 Benefits of Using ECU Programmers

Using ECU programmers offers several benefits:

- Accurate Diagnostics: Accurately diagnose software-related issues.

- Efficient Reprogramming: Efficiently reprogram ECUs with updated software.

- Data Recovery: Recover valuable data from damaged ECUs.

6.2 Diagnostic Scanners

Diagnostic scanners provide detailed diagnostic information and fault codes, helping technicians identify and resolve issues quickly. These tools are essential for efficient ECU testing and troubleshooting.

6.2.1 Features of Diagnostic Scanners

Key features of diagnostic scanners include:

- Fault Code Reading: Ability to read and clear diagnostic fault codes (DTCs).

- Live Data Streaming: Real-time data streaming for monitoring ECU parameters.

- Component Testing: Capability to test individual components and circuits.

- Vehicle Coverage: Extensive vehicle coverage for a wide range of makes and models.

6.2.2 Benefits of Using Diagnostic Scanners

Using diagnostic scanners offers several benefits:

- Quick Diagnostics: Quickly identify and diagnose ECU issues.

- Accurate Troubleshooting: Accurately troubleshoot problems with detailed diagnostic information.

- Reduced Downtime: Reduce downtime by quickly resolving ECU issues.

6.3 Multimeters

Multimeters are essential tools for measuring voltage, current, and resistance in electronic circuits. These tools are used to test ECU components, diagnose electrical issues, and ensure proper functioning.

6.3.1 Features of Multimeters

Key features of multimeters include:

- Voltage Measurement: Ability to measure DC and AC voltage.

- Current Measurement: Ability to measure DC and AC current.

- Resistance Measurement: Ability to measure resistance in ohms.

- Continuity Testing: Continuity testing to check for broken circuits.

6.3.2 Benefits of Using Multimeters

Using multimeters offers several benefits:

- Accurate Testing: Accurately test ECU components and circuits.

- Electrical Issue Diagnosis: Diagnose electrical issues in ECUs and related systems.

- Component Verification: Verify the proper functioning of electronic components.

6.4 Soldering Stations

Soldering stations are essential tools for the safe removal and replacement of electronic components on ECU circuit boards. These tools provide precise temperature control and allow for delicate soldering work.

6.4.1 Features of Soldering Stations

Key features of soldering stations include:

- Temperature Control: Precise temperature control for soldering delicate components.

- Interchangeable Tips: Interchangeable tips for different soldering tasks.

- ESD Protection: Electrostatic discharge (ESD) protection to prevent damage to components.

- Magnification: Magnification features for detailed soldering work.

6.4.2 Benefits of Using Soldering Stations

Using soldering stations offers several benefits:

- Safe Component Removal: Safely remove and replace electronic components on ECU circuit boards.

- Precise Soldering: Perform precise soldering work for reliable connections.

- Component Repair: Repair damaged ECU circuit boards by replacing faulty components.

Automotive Recycling

Automotive Recycling

7. Remote Support for Complex ECU Recycling Issues

When should I seek remote support for ECU recycling? You should seek remote support for ECU recycling when encountering complex diagnostic issues, software problems, or component recovery challenges. Expert assistance can ensure efficient and accurate recycling.

Remote support for complex ECU recycling issues provides technicians with access to expert knowledge and assistance, enabling them to resolve challenging problems quickly and efficiently. This can save time, reduce errors, and improve the overall efficiency of ECU recycling processes.

- Diagnostic Assistance: Expert assistance in diagnosing complex ECU issues.

- Software Support: Support for software-related problems and reprogramming tasks.

- Component Recovery Guidance: Guidance on safely and effectively recovering valuable components.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers remote support services to help automotive technicians overcome challenges in ECU recycling. According to a survey by the Technology Services Industry Association (TSIA), remote support can reduce the time required to resolve technical issues by up to 50%. (TSIA, “The State of Remote Support,” 2020).

7.1 Diagnostic Assistance

Remote diagnostic assistance provides technicians with expert guidance in diagnosing complex ECU issues. This can help them quickly identify the root cause of problems and implement effective solutions.

7.1.1 Expert Guidance

Expert technicians provide step-by-step guidance on diagnosing ECU issues, using advanced diagnostic tools and techniques.

7.1.2 Remote Diagnostics

Remote diagnostics allows experts to access ECU data and perform diagnostic tests remotely, providing real-time assistance.

7.1.3 Troubleshooting Support

Troubleshooting support helps technicians identify and resolve issues by providing detailed instructions and troubleshooting tips.

7.2 Software Support

Remote software support provides technicians with assistance in resolving software-related problems and performing reprogramming tasks. This can help them update ECU software, fix bugs, and improve performance.

7.2.1 Software Updates

Remote assistance in updating ECU software to the latest versions.

7.2.2 Bug Fixes

Support for identifying and fixing software bugs and glitches.

7.2.3 Reprogramming Assistance

Guidance on safely and effectively reprogramming ECUs.

7.3 Component Recovery Guidance

Remote component recovery guidance provides technicians with expert advice on safely and effectively recovering valuable components from ECUs. This can help them maximize the value of recycled ECUs and minimize environmental impact.

7.3.1 Safe Removal Techniques

Guidance on using safe removal techniques to prevent damage to components.

7.3.2 Best Practices

Best practices for recovering valuable materials from ECUs.

7.3.3 Environmental Considerations

Considerations for minimizing environmental impact during component recovery.

8. Training Programs for Automotive Technicians on ECU Recycling

Why should automotive technicians participate in ECU recycling training programs? Automotive technicians should participate in ECU recycling training programs to enhance their skills, learn best practices, and stay updated with industry standards for responsible waste management.

Training programs for automotive technicians on ECU recycling provide them with the knowledge and skills they need to perform ECU recycling efficiently and responsibly. These programs cover a range of topics, including diagnostic techniques, component recovery, and environmental compliance.

- Diagnostic Techniques: Training on using advanced diagnostic tools to identify and resolve ECU issues.

- Component Recovery: Instruction on safely and effectively recovering valuable components from ECUs.

- Environmental Compliance: Information on environmental regulations and best practices for ECU recycling.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers training programs to help automotive technicians advance their careers in ECU recycling. According to a study by the National Institute for Automotive Service Excellence (ASE), certified technicians earn higher wages and have better job opportunities. (ASE, “The Value of Certification,” 2017).

8.1 Diagnostic Techniques

Training on diagnostic techniques provides technicians with the skills they need to accurately diagnose ECU issues and perform effective repairs.

8.1.1 Advanced Diagnostic Tools

Instruction on using advanced diagnostic tools such as ECU programmers, diagnostic scanners, and multimeters.

8.1.2 Troubleshooting Strategies

Strategies for troubleshooting complex ECU problems.

8.1.3 Real-World Case Studies

Real-world case studies to illustrate diagnostic techniques.

8.2 Component Recovery

Training on component recovery provides technicians with the knowledge and skills they need to safely and effectively recover valuable components from ECUs.

8.2.1 Safe Removal Practices

Safe removal practices for handling electronic components.

8.2.2 Best Practices

Best practices for recovering valuable materials from ECUs.

8.2.3 Environmental Considerations

Considerations for minimizing environmental impact during component recovery.

8.3 Environmental Compliance

Training on environmental compliance provides technicians with the information they need to adhere to environmental regulations and best practices for ECU recycling.

8.3.1 Environmental Regulations

Overview of environmental regulations related to ECU recycling.

8.3.2 Waste Management

Proper waste management practices for handling hazardous materials.

8.3.3 Sustainability Practices

Sustainable practices for minimizing environmental impact during ECU recycling.

9. Benefits of Using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU Recycling

What are the benefits of using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU recycling? The benefits of using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU recycling include access to advanced tools, expert support, comprehensive training, and cost-effective solutions. This ensures efficient and responsible recycling.

Using CAR-DIAGNOSTIC-TOOL.EDU.VN for ECU recycling offers several benefits:

- Access to Advanced Tools: High-quality diagnostic and recycling tools.

- Expert Support: Remote support and guidance from experienced technicians.

- Comprehensive Training: Training programs to enhance your skills and knowledge.

- Cost-Effective Solutions: Solutions that help you save time and money.

By leveraging these benefits, automotive technicians can improve their ECU recycling practices and contribute to a more sustainable future. According to a report by McKinsey & Company, investing in sustainable practices can improve a company’s financial performance and reduce its environmental impact. (McKinsey & Company, “Sustainability’s Strategic Worth,” 2020).

9.1 Access to Advanced Tools

CAR-DIAGNOSTIC-TOOL.EDU.VN provides access to a wide range of advanced tools for ECU recycling, including ECU programmers, diagnostic scanners, multimeters, and soldering stations.

9.1.1 High-Quality Equipment

High-quality equipment that is reliable and durable.

9.1.2 Latest Technology

Access to the latest technology for efficient and accurate ECU recycling.

9.1.3 Tool Selection

A wide selection of tools to meet your specific needs.

9.2 Expert Support

CAR-DIAGNOSTIC-TOOL.EDU.VN offers expert support from experienced technicians who can provide guidance and assistance with complex ECU recycling issues.

9.2.1 Remote Assistance

Remote assistance for diagnosing and resolving ECU issues.

9.2.2 Troubleshooting Tips

Troubleshooting tips and best practices for ECU recycling.

9.2.3 Technical Expertise

Access to technical expertise from industry professionals.

9.3 Comprehensive Training

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive training programs to help automotive technicians enhance their skills and knowledge in ECU recycling.

9.3.1 Online Courses

Online courses covering a range of ECU recycling topics.

9.3.2 Hands-On Workshops

Hands-on workshops for practical experience.

9.3.3 Certification Programs

Certification programs to demonstrate your expertise.

9.4 Cost-Effective Solutions

CAR-DIAGNOSTIC-TOOL.EDU.VN offers cost-effective solutions for ECU recycling, helping you save time and money while improving your recycling practices.

9.4.1 Competitive Pricing

Competitive pricing on tools and services.

9.4.2 Time Savings

Time savings through efficient diagnostic and recycling processes.

9.4.3 Reduced Waste

Reduced waste through effective component recovery and recycling.

10. Frequently Asked Questions About ECU Shred Days

What are the frequently asked questions about ECU shred days? Frequently asked questions about ECU shred days cover topics such as event schedules, accepted materials, preparation guidelines, and environmental impact. Understanding these FAQs can help you participate effectively.

Here are some frequently asked questions about ECU shred days:

- When and where are ECU shred days held?

- What types of materials are accepted at ECU shred days?

- How should I prepare my materials for ECU shred days?

- What happens to the materials collected at ECU shred days?

- What are the environmental benefits of participating in ECU shred days?

- Are there any costs associated with participating in ECU shred days?

- Can businesses participate in ECU shred days?

- What diagnostic tools are recommended for ECU recycling?

- How can I get remote support for ECU recycling issues?

- Are there training programs for automotive technicians on ECU recycling?

Answering these questions can help individuals and businesses participate effectively in ECU shred days and contribute to a more sustainable future. According to a survey by the Pew Research Center, most Americans believe that protecting the environment should be a top priority for the country. (Pew Research Center, “Public Opinion on Environmental Issues,” 2021).

10.1 When and Where Are ECU Shred Days Held?

ECU shred days are typically held on specific dates and locations announced by local governments, community organizations, and automotive industry associations. Check their websites and contact them for schedules.

10.2 What Types of Materials Are Accepted at ECU Shred Days?

Accepted materials typically include electronic control units (ECUs), batteries, metals, plastics, and fluids from vehicles. Check the specific requirements of the event you plan to attend.

10.3 How Should I Prepare My Materials for ECU Shred Days?

Prepare materials by sorting them into categories, cleaning them to remove contaminants, and disassembling components as needed. Follow the instructions provided by the event organizers.

10.4 What Happens to the Materials Collected at ECU Shred Days?

The materials collected are sent to recycling centers, where they are processed and recycled into new products. This helps conserve resources and reduce waste.

10.5 What Are the Environmental Benefits of Participating in ECU Shred Days?

Participating in ECU shred days helps reduce pollution, conserve resources, and minimize landfill waste. This contributes to a cleaner and more sustainable environment.

10.6 Are There Any Costs Associated with Participating in ECU Shred Days?

Some ECU shred days may be