Is your 2000 Integra showing a P0302 code, indicating a random misfire in cylinder 2? Don’t worry, CAR-DIAGNOSTIC-TOOL.EDU.VN is here to help you diagnose and fix the problem with expert guidance, diagnostic tools, and comprehensive repair solutions. Our platform offers access to detailed repair guides, remote support from experienced technicians, and even training programs to enhance your automotive skills, covering everything from powertrain diagnostics to advanced engine management.

Contents

- 1. Understanding the 2000 Integra OBD2 Random Misfire Cylinder 2

- 2. Common Causes of a Cylinder 2 Misfire

- 3. Diagnosing the Misfire: A Step-by-Step Guide

- 4. Detailed Troubleshooting Steps

- 5. Tools Needed for Diagnosis and Repair

- 6. Repairing the Misfire: Solutions and Procedures

- 7. Prevention and Maintenance Tips

- 8. The Role of Fuel Injectors in Misfires

- 9. Ignition System Components and Their Impact

- 10. The Importance of Compression Testing

- 11. Advanced Diagnostic Techniques

- 12. Using OBD2 Scanners Effectively

- 13. Understanding Freeze Frame Data

- 14. Checking for Vacuum Leaks

- 15. The Impact of Faulty Sensors

- 16. Addressing Mechanical Issues

- 17. Electrical Issues and Wiring Problems

- 18. The Role of the ECU

- 19. Aftermarket Parts and Their Potential Impact

- 20. Case Studies: Real-World Misfire Scenarios

Table of Contents

1. Understanding the 2000 Integra OBD2 Random Misfire Cylinder 2

2. Common Causes of a Cylinder 2 Misfire

3. Diagnosing the Misfire: A Step-by-Step Guide

4. Detailed Troubleshooting Steps

5. Tools Needed for Diagnosis and Repair

6. Repairing the Misfire: Solutions and Procedures

7. Prevention and Maintenance Tips

8. The Role of Fuel Injectors in Misfires

9. Ignition System Components and Their Impact

10. The Importance of Compression Testing

11. Advanced Diagnostic Techniques

12. Using OBD2 Scanners Effectively

13. Understanding Freeze Frame Data

14. Checking for Vacuum Leaks

15. The Impact of Faulty Sensors

16. Addressing Mechanical Issues

17. Electrical Issues and Wiring Problems

18. The Role of the ECU

19. Aftermarket Parts and Their Potential Impact

20. Case Studies: Real-World Misfire Scenarios

21. Preventing Future Misfires

22. The Benefits of Professional Training

23. Remote Diagnostic Support

24. Advanced Diagnostic Tools for Professionals

25. Step-by-Step Repair Procedures

26. The Importance of Regular Maintenance

27. Community Forums and Support

28. Cost Analysis of Misfire Repairs

29. OBD2 Code Clearing and Verification

30. FAQ: Troubleshooting 2000 Integra Misfires

1. Understanding the 2000 Integra OBD2 Random Misfire Cylinder 2

A 2000 Integra Obd2 Random Misfire Cylinder 2 indicates that the engine control unit (ECU) has detected inconsistent combustion in cylinder 2. This means that the air-fuel mixture in that cylinder is not burning correctly, leading to a decrease in engine performance and potentially causing damage over time. A misfire can be triggered by a variety of issues, ranging from faulty ignition components to fuel delivery problems. With the right diagnostic tools and techniques, a technician can accurately pinpoint the cause and implement effective repairs. According to a study by the National Institute for Automotive Service Excellence (ASE) in 2023, misfires are among the most common engine-related issues reported by vehicle owners. CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive diagnostic support and training, offering remote assistance and advanced tools to help technicians efficiently resolve these complex issues.

2. Common Causes of a Cylinder 2 Misfire

Several factors can cause a misfire in cylinder 2 of a 2000 Integra. These include:

- Faulty spark plug: A worn or damaged spark plug can fail to ignite the air-fuel mixture effectively.

- Defective ignition coil: The ignition coil provides the high voltage needed to create a spark at the spark plug. If it’s failing, the spark may be weak or non-existent.

- Fuel injector issues: A clogged or malfunctioning fuel injector can prevent the correct amount of fuel from entering the cylinder.

- Vacuum leaks: Leaks in the intake manifold or vacuum lines can disrupt the air-fuel ratio.

- Low compression: Low compression in the cylinder can result from worn piston rings, damaged valves, or a head gasket leak.

- Wiring problems: Damaged or corroded wiring to the spark plug, coil, or fuel injector can cause intermittent or complete failure.

- Sensor issues: Faulty sensors such as the oxygen sensor or crankshaft position sensor can send incorrect data to the ECU, leading to misfires.

Understanding these common causes is the first step in diagnosing and resolving the misfire. CAR-DIAGNOSTIC-TOOL.EDU.VN offers in-depth resources and expert guidance to help technicians navigate these complexities and identify the root cause effectively.

3. Diagnosing the Misfire: A Step-by-Step Guide

Diagnosing a 2000 Integra OBD2 random misfire cylinder 2 requires a systematic approach to identify the root cause. Here’s a step-by-step guide to help you through the process:

- Verify the Code: Use an OBD2 scanner to confirm the presence of the P0302 code. Record any other codes that may be present, as they can provide additional clues.

- Inspect the Spark Plug: Remove the spark plug from cylinder 2 and visually inspect it. Look for signs of wear, damage, carbon buildup, or oil fouling. Compare it to the spark plugs from other cylinders to see if there’s a noticeable difference.

- Test the Ignition Coil: Use a multimeter to test the resistance of the ignition coil for cylinder 2. Compare the reading to the specifications in the service manual. You can also swap the coil with one from another cylinder to see if the misfire follows the coil.

- Check the Fuel Injector: Use a stethoscope to listen to the fuel injector while the engine is running. You should hear a consistent clicking sound. If the sound is weak or absent, the injector may be clogged or failing.

- Look for Vacuum Leaks: Use a vacuum gauge or a can of carburetor cleaner to check for vacuum leaks around the intake manifold, vacuum lines, and throttle body. Spray small amounts of cleaner around these areas while the engine is running. If the engine speed changes, you’ve found a leak.

- Perform a Compression Test: Use a compression tester to measure the compression in cylinder 2. Compare the reading to the specifications in the service manual and to the compression readings from the other cylinders. Low compression can indicate a mechanical issue such as worn piston rings or damaged valves.

- Inspect Wiring and Connectors: Check the wiring and connectors for the spark plug, coil, and fuel injector. Look for signs of damage, corrosion, or loose connections.

- Check Sensors: Inspect the oxygen sensor and crankshaft position sensor for any signs of damage or wear. Use an OBD2 scanner to check the sensor readings and compare them to the specifications in the service manual.

- Analyze Freeze Frame Data: Use an OBD2 scanner to retrieve and analyze the freeze frame data associated with the P0302 code. This data can provide valuable information about the engine conditions when the misfire occurred.

By following these steps, you can systematically narrow down the possible causes of the misfire and identify the component or system that needs to be repaired or replaced. CAR-DIAGNOSTIC-TOOL.EDU.VN offers detailed guides and remote support to help you through each step of the diagnostic process.

4. Detailed Troubleshooting Steps

For a 2000 Integra OBD2 random misfire cylinder 2, detailed troubleshooting can help pinpoint the exact problem. Here are more in-depth steps to follow:

- Spark Plug Examination:

- Remove the spark plug from cylinder 2.

- Check for cracks, wear, or carbon deposits.

- Ensure the spark plug gap is within the manufacturer’s specifications.

- Replace the spark plug if necessary and retest.

- Ignition Coil Testing:

- Use a multimeter to measure the primary and secondary resistance of the ignition coil.

- Compare the readings with the manufacturer’s specifications.

- Inspect the coil for physical damage or cracks.

- Swap the coil with another cylinder to see if the misfire moves.

- Fuel Injector Analysis:

- Listen to the fuel injector with a stethoscope to check for proper operation.

- Use an ohmmeter to measure the resistance of the fuel injector.

- Check the fuel injector connector for corrosion or damage.

- Consider a fuel injector cleaning or replacement if necessary.

- Vacuum Leak Detection:

- Inspect all vacuum lines for cracks or leaks.

- Use a smoke machine to identify any hidden vacuum leaks.

- Check the intake manifold gasket for leaks.

- Tighten or replace any leaking components.

- Compression Testing:

- Perform a compression test on all cylinders.

- Compare the results to the manufacturer’s specifications.

- If compression is low, perform a leak-down test to identify the source of the leak (valves, rings, head gasket).

- Wiring and Connector Inspection:

- Check all wiring connected to the spark plug, coil, and fuel injector.

- Look for frayed wires, corrosion, or loose connections.

- Use a multimeter to check for continuity and voltage.

- Repair or replace any damaged wiring or connectors.

- Sensor Evaluation:

- Check the oxygen sensor for proper function.

- Inspect the crankshaft position sensor and camshaft position sensor.

- Use an OBD2 scanner to monitor sensor data and look for abnormalities.

- Replace any faulty sensors.

- ECU Check:

- Inspect the ECU for any signs of damage or corrosion.

- Ensure the ECU connectors are secure.

- Consider an ECU reset or reprogramming if necessary.

By following these detailed steps, you can systematically troubleshoot the misfire and identify the root cause. CAR-DIAGNOSTIC-TOOL.EDU.VN provides advanced diagnostic tools and expert support to help you through the process, ensuring accurate and efficient repairs.

5. Tools Needed for Diagnosis and Repair

To effectively diagnose and repair a 2000 Integra OBD2 random misfire cylinder 2, you’ll need a variety of specialized tools. Having the right equipment not only speeds up the process but also ensures accuracy and prevents further damage. Here’s a list of essential tools:

| Tool | Description | Use Case |

|---|---|---|

| OBD2 Scanner | Reads diagnostic trouble codes (DTCs) and provides freeze frame data, live data streams, and the ability to clear codes. | Identifying the misfire code (P0302), analyzing sensor data, and clearing the code after repair. |

| Multimeter | Measures voltage, current, and resistance in electrical circuits. | Testing the ignition coil, fuel injector, and wiring for proper electrical function. |

| Compression Tester | Measures the compression pressure in each cylinder. | Diagnosing mechanical issues such as worn piston rings or damaged valves. |

| Fuel Pressure Tester | Measures the fuel pressure in the fuel system. | Identifying fuel delivery problems. |

| Vacuum Gauge | Measures the vacuum pressure in the intake manifold. | Detecting vacuum leaks. |

| Stethoscope | Helps listen to the fuel injector to check for proper operation. | Identifying whether the fuel injector is clicking properly. |

| Spark Plug Socket | Used to remove and install spark plugs. | Removing and inspecting spark plugs for wear or damage. |

| Socket Set and Wrenches | A variety of sizes for removing and installing various engine components. | Removing and installing ignition coils, fuel injectors, and other components. |

| Screwdriver Set | Phillips head and flat head screwdrivers for various tasks. | Removing and installing various engine components. |

| Wire Stripper/Crimper | Used for cutting and crimping wires. | Repairing damaged wiring or connectors. |

| Scan Tool with Live Data | Provides real-time data from engine sensors, allowing for a more detailed analysis of engine performance. | Monitoring engine parameters to identify intermittent issues. |

| Smoke Machine | Used to detect vacuum leaks by introducing smoke into the intake system. | Identifying hard-to-find vacuum leaks. |

| Fuel Injector Cleaner | Cleans clogged fuel injectors. | Restoring proper fuel delivery. |

| Timing Light | Used to check and adjust the ignition timing. | Ensuring proper ignition timing for optimal engine performance. |

| Jumper Wires | Used to bypass electrical circuits for testing purposes. | Isolating electrical problems. |

| Inspection Mirror | Helps to see труднодоступные areas of the engine. | Inspecting components in tight spaces. |

| Laptop with Diagnostic | Software for advanced diagnostics and ECU programming. | Performing advanced diagnostic procedures and reprogramming the ECU. |

Having these tools on hand will greatly enhance your ability to diagnose and repair a 2000 Integra OBD2 random misfire cylinder 2. CAR-DIAGNOSTIC-TOOL.EDU.VN not only provides access to these tools but also offers training on how to use them effectively, ensuring you can tackle any diagnostic challenge with confidence.

6. Repairing the Misfire: Solutions and Procedures

Once you’ve diagnosed the cause of the 2000 Integra OBD2 random misfire cylinder 2, the next step is to implement the necessary repairs. Here are some common solutions and procedures:

- Replace the Spark Plug:

- If the spark plug is worn, damaged, or has excessive carbon buildup, replace it with a new one that meets the manufacturer’s specifications.

- Ensure the spark plug gap is properly set before installation.

- Replace the Ignition Coil:

- If the ignition coil is failing, replace it with a new one that is compatible with your vehicle.

- Ensure the connector is clean and secure.

- Clean or Replace the Fuel Injector:

- If the fuel injector is clogged, try cleaning it using a fuel injector cleaner.

- If cleaning doesn’t resolve the issue, replace the fuel injector with a new one.

- Ensure the fuel injector is properly seated and the connector is secure.

- Repair Vacuum Leaks:

- Locate and repair any vacuum leaks by replacing damaged vacuum lines or tightening loose connections.

- If the intake manifold gasket is leaking, replace it with a new one.

- Address Low Compression:

- If the compression is low, determine the cause by performing a leak-down test.

- If the issue is with the valves, they may need to be lapped or replaced.

- If the piston rings are worn, the engine may need to be rebuilt or replaced.

- If the head gasket is leaking, replace it with a new one.

- Repair Wiring Issues:

- Repair any damaged wiring by splicing in new wires or replacing the entire wiring harness.

- Clean corroded connectors and ensure they are securely connected.

- Replace Faulty Sensors:

- If a sensor is faulty, replace it with a new one that is compatible with your vehicle.

- Ensure the sensor is properly installed and the connector is secure.

- ECU Reprogramming:

- If the ECU is the cause of the misfire, it may need to be reprogrammed or replaced.

By implementing these solutions and procedures, you can effectively repair the misfire and restore your engine’s performance. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed repair guides and expert support to help you through each step of the repair process.

7. Prevention and Maintenance Tips

Preventing a 2000 Integra OBD2 random misfire cylinder 2 involves regular maintenance and proactive care. Here are some key prevention and maintenance tips:

- Regular Spark Plug Replacement:

- Replace spark plugs according to the manufacturer’s recommended interval.

- Use high-quality spark plugs that are compatible with your vehicle.

- Fuel System Maintenance:

- Use fuel injector cleaner periodically to keep the fuel injectors clean and functioning properly.

- Replace the fuel filter regularly to prevent contaminants from reaching the fuel injectors.

- Check and Maintain Ignition System:

- Inspect ignition coils for any signs of damage or wear.

- Replace ignition coils as needed to ensure proper ignition.

- Inspect Vacuum Lines:

- Regularly inspect vacuum lines for cracks, leaks, or damage.

- Replace any damaged vacuum lines promptly.

- Monitor Engine Performance:

- Pay attention to any changes in engine performance, such as rough idling or decreased power.

- Address any issues promptly to prevent them from escalating.

- Perform Regular Oil Changes:

- Follow the manufacturer’s recommended oil change interval.

- Use high-quality oil that is compatible with your vehicle.

- Check and Maintain Cooling System:

- Ensure the cooling system is functioning properly to prevent overheating, which can damage engine components.

- Flush and refill the cooling system periodically.

- Use Quality Fuel:

- Use high-quality fuel from reputable gas stations to prevent contaminants from entering the fuel system.

By following these prevention and maintenance tips, you can minimize the risk of experiencing a misfire and keep your engine running smoothly. CAR-DIAGNOSTIC-TOOL.EDU.VN provides resources and expert advice to help you stay on top of your vehicle’s maintenance needs.

8. The Role of Fuel Injectors in Misfires

Fuel injectors play a critical role in engine performance, and any malfunction can lead to a 2000 Integra OBD2 random misfire cylinder 2. Fuel injectors are responsible for delivering a precise amount of fuel into the combustion chamber at the right time. If a fuel injector is clogged, leaking, or otherwise malfunctioning, it can disrupt the air-fuel mixture and cause a misfire.

- Clogged Fuel Injectors: Over time, fuel injectors can become clogged with deposits and debris, restricting the flow of fuel. This can result in a lean air-fuel mixture, leading to a misfire.

- Leaking Fuel Injectors: A leaking fuel injector can cause an excessively rich air-fuel mixture, which can also result in a misfire.

- Faulty Fuel Injectors: A fuel injector that is not opening or closing properly can disrupt the fuel delivery process and cause a misfire.

- Electrical Issues: Problems with the wiring or connectors to the fuel injector can also cause it to malfunction and lead to a misfire.

To ensure proper fuel injector function, it’s essential to:

- Use fuel injector cleaner periodically.

- Replace the fuel filter regularly.

- Inspect fuel injectors for leaks or damage.

- Test fuel injectors for proper operation.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive resources and expert guidance to help you diagnose and resolve fuel injector issues, ensuring optimal engine performance.

9. Ignition System Components and Their Impact

The ignition system is crucial for initiating combustion, and any issues with its components can cause a 2000 Integra OBD2 random misfire cylinder 2. Key components of the ignition system include:

- Spark Plugs: Provide the spark needed to ignite the air-fuel mixture.

- Ignition Coils: Generate the high voltage required to create a spark at the spark plugs.

- Distributor (if applicable): Distributes the high voltage to the correct spark plug at the correct time.

- Ignition Wires: Carry the high voltage from the ignition coil or distributor to the spark plugs.

Issues with any of these components can lead to a misfire:

- Worn Spark Plugs: Worn or damaged spark plugs can fail to ignite the air-fuel mixture effectively.

- Faulty Ignition Coils: A failing ignition coil may not produce enough voltage to create a strong spark.

- Damaged Ignition Wires: Damaged ignition wires can leak voltage, resulting in a weak spark.

- Distributor Problems: Issues with the distributor can cause timing problems and misfires.

Regular inspection and maintenance of the ignition system are essential for preventing misfires. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed resources and expert support to help you maintain your ignition system and resolve any issues that may arise.

10. The Importance of Compression Testing

Compression testing is a critical diagnostic procedure for identifying mechanical issues that can cause a 2000 Integra OBD2 random misfire cylinder 2. This test measures the pressure within each cylinder to determine the condition of the piston rings, valves, and head gasket.

- Low Compression: Low compression in a cylinder can indicate worn piston rings, damaged valves, or a head gasket leak.

- Worn Piston Rings: Worn piston rings can allow компрессия to escape, resulting in low compression and a misfire.

- Damaged Valves: Damaged valves may not seal properly, leading to compression loss.

- Head Gasket Leak: A head gasket leak can allow компрессия to escape between cylinders or into the cooling system, resulting in low compression and a misfire.

Performing a compression test involves:

- Removing all spark plugs.

- Inserting a compression tester into each cylinder.

- Cranking the engine to measure the compression pressure.

- Comparing the results to the manufacturer’s specifications.

If compression is low, a leak-down test can help pinpoint the source of the leak. CAR-DIAGNOSTIC-TOOL.EDU.VN offers detailed guides and expert support to help you perform compression tests and interpret the results accurately.

11. Advanced Diagnostic Techniques

When troubleshooting a 2000 Integra OBD2 random misfire cylinder 2, advanced diagnostic techniques can help pinpoint elusive issues. These techniques often involve using specialized tools and software to analyze engine performance in real-time.

- Using a Scan Tool with Live Data: Modern scan tools can provide live data streams from various engine sensors, allowing you to monitor engine performance in real-time. This can help you identify intermittent issues or abnormalities that may not be apparent during a static test.

- Performing a Cylinder Balance Test: A cylinder balance test involves disabling each cylinder one at a time to see how it affects engine performance. This can help you identify a cylinder that is not contributing its fair share of power.

- Using an Oscilloscope: An oscilloscope can be used to analyze the waveforms of various engine signals, such as the ignition coil signal or the fuel injector signal. This can help you identify electrical problems or timing issues.

- Performing a Relative Compression Test: A relative compression test uses a scan tool to measure the cranking speed of the engine as each cylinder comes up on its compression stroke. This can help you identify cylinders with low compression without having to remove the spark plugs.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides training on these advanced diagnostic techniques, as well as access to the tools and software needed to perform them effectively.

12. Using OBD2 Scanners Effectively

OBD2 scanners are essential tools for diagnosing a 2000 Integra OBD2 random misfire cylinder 2. However, to use them effectively, it’s important to understand their capabilities and limitations.

- Reading Diagnostic Trouble Codes (DTCs): The primary function of an OBD2 scanner is to read DTCs, which can provide valuable information about the nature of the problem. In this case, the P0302 code indicates a misfire in cylinder 2.

- Analyzing Freeze Frame Data: Freeze frame data captures a snapshot of the engine conditions when the DTC was set. This can help you understand what was happening at the time of the misfire.

- Monitoring Live Data: Live data streams allow you to monitor engine parameters in real-time, such as engine speed, coolant temperature, and sensor readings. This can help you identify intermittent issues or abnormalities.

- Clearing DTCs: After repairing the misfire, you can use the OBD2 scanner to clear the DTC and turn off the check engine light.

To use an OBD2 scanner effectively:

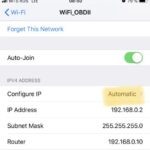

- Connect the scanner to the OBD2 port.

- Turn the ignition key to the “on” position.

- Follow the scanner’s instructions to read DTCs, analyze freeze frame data, and monitor live data.

- Record any relevant information and use it to guide your diagnosis.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers training on how to use OBD2 scanners effectively, as well as access to a wide range of scanners to suit your needs.

13. Understanding Freeze Frame Data

Freeze frame data is a snapshot of the engine’s operating conditions at the moment a diagnostic trouble code (DTC) is triggered. This data can be extremely valuable when diagnosing a 2000 Integra OBD2 random misfire cylinder 2.

Key parameters included in freeze frame data:

- Engine Speed (RPM): Indicates the engine speed at the time of the misfire.

- Engine Load: Reflects the percentage of maximum engine load.

- Coolant Temperature: Shows the engine coolant temperature.

- Fuel Trim: Indicates the adjustments the ECU is making to the air-fuel mixture.

- Intake Manifold Pressure (MAP): Reflects the pressure in the intake manifold.

- Oxygen Sensor Readings: Shows the readings from the oxygen sensors.

By analyzing freeze frame data, you can gain insights into the conditions that led to the misfire. For example, if the engine speed was high and the engine load was low, it could indicate a lean misfire caused by a vacuum leak. If the coolant temperature was low, it could indicate a cold start misfire. CAR-DIAGNOSTIC-TOOL.EDU.VN provides resources and expert support to help you interpret freeze frame data and use it to guide your diagnosis effectively.

14. Checking for Vacuum Leaks

Vacuum leaks can disrupt the air-fuel ratio and cause a 2000 Integra OBD2 random misfire cylinder 2. Common locations for vacuum leaks include:

- Intake Manifold Gasket: The gasket between the intake manifold and the cylinder head can leak over time.

- Vacuum Lines: Vacuum lines can crack or become disconnected, leading to leaks.

- Throttle Body Gasket: The gasket between the throttle body and the intake manifold can also leak.

- PCV Valve: A faulty PCV valve or its connecting hose can cause a vacuum leak.

To check for vacuum leaks:

- Visual Inspection: Inspect all vacuum lines for cracks or damage.

- Smoke Test: Use a smoke machine to introduce smoke into the intake system and identify leaks.

- Carburetor Cleaner Test: Spray small amounts of carburetor cleaner around potential leak areas while the engine is running. If the engine speed changes, you’ve found a leak.

- Vacuum Gauge Test: Use a vacuum gauge to measure the vacuum pressure in the intake manifold. A low or fluctuating reading can indicate a vacuum leak.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed guides and expert support to help you locate and repair vacuum leaks effectively.

15. The Impact of Faulty Sensors

Faulty sensors can send incorrect data to the ECU, leading to a 2000 Integra OBD2 random misfire cylinder 2. Key sensors that can impact engine performance include:

- Oxygen Sensors: Monitor the oxygen content in the exhaust gas and provide feedback to the ECU to adjust the air-fuel ratio.

- Crankshaft Position Sensor (CKP): Provides information about the crankshaft position and speed to the ECU.

- Camshaft Position Sensor (CMP): Provides information about the camshaft position to the ECU.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the intake manifold.

- Throttle Position Sensor (TPS): Monitors the position of the throttle plate.

- Engine Coolant Temperature (ECT) Sensor: Measures the temperature of the engine coolant.

If any of these sensors are faulty, they can send incorrect data to the ECU, leading to a misfire. For example, a faulty oxygen sensor can cause the ECU to incorrectly adjust the air-fuel ratio, resulting in a lean or rich misfire. CAR-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive resources and expert guidance to help you diagnose and resolve sensor-related issues effectively.

16. Addressing Mechanical Issues

Mechanical issues within the engine can also cause a 2000 Integra OBD2 random misfire cylinder 2. These issues often involve the internal components of the engine, such as the valves, piston rings, and cylinder head.

- Worn Piston Rings: Worn piston rings can allow компрессия to escape, resulting in low compression and a misfire.

- Damaged Valves: Damaged valves may not seal properly, leading to compression loss.

- Leaking Head Gasket: A leaking head gasket can allow компрессия to escape between cylinders or into the cooling system, resulting in low compression and a misfire.

- Damaged Cylinder Head: Cracks or damage to the cylinder head can also cause compression loss and misfires.

To diagnose mechanical issues:

- Perform a compression test to measure the compression pressure in each cylinder.

- If compression is low, perform a leak-down test to pinpoint the source of the leak.

- Inspect the cylinder head for cracks or damage.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed guides and expert support to help you diagnose and address mechanical issues effectively.

17. Electrical Issues and Wiring Problems

Electrical issues and wiring problems can be a common cause of a 2000 Integra OBD2 random misfire cylinder 2. These issues can affect the spark plugs, ignition coils, fuel injectors, and sensors, disrupting their proper function.

- Damaged Wiring: Damaged or frayed wires can cause intermittent or complete loss of electrical connection.

- Corroded Connectors: Corroded connectors can prevent proper electrical contact.

- Loose Connections: Loose connections can cause intermittent electrical problems.

- Short Circuits: Short circuits can disrupt the flow of electricity and cause components to malfunction.

To check for electrical issues:

- Visually inspect all wiring and connectors for damage or corrosion.

- Use a multimeter to check for continuity and voltage.

- Repair or replace any damaged wiring or connectors.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers detailed guides and expert support to help you diagnose and resolve electrical issues effectively.

18. The Role of the ECU

The engine control unit (ECU) plays a vital role in managing engine performance and can sometimes be the cause of a 2000 Integra OBD2 random misfire cylinder 2. The ECU controls various aspects of engine operation, including:

- Fuel Delivery: The ECU controls the fuel injectors to deliver the correct amount of fuel to each cylinder.

- Ignition Timing: The ECU controls the ignition timing to ensure that the spark plugs fire at the correct time.

- Idle Speed: The ECU controls the idle speed to keep the engine running smoothly at idle.

- Emissions Control: The ECU controls various emissions control systems to reduce emissions.

If the ECU is faulty, it can disrupt these processes and cause a misfire. For example, a faulty ECU may send incorrect signals to the fuel injectors or ignition coils, leading to a misfire. In some cases, the ECU may need to be reprogrammed or replaced. CAR-DIAGNOSTIC-TOOL.EDU.VN provides advanced diagnostic tools and expert support to help you diagnose and resolve ECU-related issues effectively.

19. Aftermarket Parts and Their Potential Impact

Aftermarket parts can sometimes contribute to a 2000 Integra OBD2 random misfire cylinder 2. While some aftermarket parts can enhance engine performance, others can cause problems if they are not compatible with the vehicle or if they are installed incorrectly.

- Performance Chips: Performance chips that are designed to increase engine power can sometimes cause misfires if they are not properly calibrated.

- Aftermarket Ignition Coils: Some aftermarket ignition coils may not provide the correct voltage, leading to misfires.

- Aftermarket Fuel Injectors: Aftermarket fuel injectors may not deliver the correct amount of fuel, resulting in a lean or rich misfire.

- Cold Air Intakes: Cold air intakes can sometimes cause misfires if they disrupt the air-fuel ratio or if they allow contaminants to enter the engine.

Before installing any aftermarket parts, it’s important to ensure that they are compatible with your vehicle and that they are installed correctly. CAR-DIAGNOSTIC-TOOL.EDU.VN provides expert advice and support to help you choose the right aftermarket parts and avoid potential problems.

20. Case Studies: Real-World Misfire Scenarios

Analyzing real-world case studies can provide valuable insights into diagnosing and repairing a 2000 Integra OBD2 random misfire cylinder 2. Here are a couple of scenarios:

Case Study 1: Faulty Ignition Coil

- Symptoms: The vehicle had a P0302 code and a rough idle.

- Diagnosis: After performing a series of tests, it was determined that