Does My Car Have Obd1 Or Obd2? Determining whether your vehicle uses OBD1 or OBD2 is crucial for proper diagnostics and repair, and CAR-DIAGNOSTIC-TOOL.EDU.VN is here to guide you through it with expert precision. Understanding the differences ensures you select the correct diagnostic tools, and with our comprehensive guides, repair solutions, and technical assistance, you’ll be well-equipped to tackle any automotive challenge. Enhance your skills with our technician training and remote support, providing a complete solution for all your automotive diagnostic needs.

Contents

- 1. What is OBD and Why Does It Matter?

- 1.1. The Evolution of OBD Systems

- 1.2. OBD1: The Early Days

- 1.3. OBD2: The Standardized System

- 2. Key Differences Between OBD1 and OBD2

- 2.1. Standardization

- 2.2. Diagnostic Trouble Codes (DTCs)

- 2.3. Data Availability

- 2.4. Connector Type and Location

- 2.5. Communication Protocols

- 3. How to Determine If Your Car Has OBD1 or OBD2

- 3.1. Check the Manufacturing Date

- 3.2. Locate the Diagnostic Connector

- 3.3. Check the Vehicle’s Emissions Sticker

- 3.4. Consult Your Vehicle’s Manual

- 3.5. Use an OBD Diagnostic Tool

- 4. Understanding OBD1 Systems in Detail

- 4.1. Manufacturer-Specific Codes

- 4.2. Location of Diagnostic Port

- 4.3. Diagnostic Procedures

- 4.4. Examples of OBD1 Systems

- 4.5. Adapters for OBD1 Systems

- 5. Exploring OBD2 Systems in Detail

- 5.1. Standardized DTCs

- 5.2. PID (Parameter Identification) Data

- 5.3. Freeze Frame Data

- 5.4. Readiness Monitors

- 5.5. Communication Protocols

- 5.6. Diagnostic Tools for OBD2

- 6. Choosing the Right Diagnostic Tool

- 6.1. Compatibility

- 6.2. Features

- 6.3. Ease of Use

- 6.4. Updates

- 6.5. Cost

- 7. Step-by-Step Guide to Diagnosing Problems with OBD1 and OBD2

- 7.1. Diagnosing Problems with OBD2

- 7.2. Diagnosing Problems with OBD1

- 8. Common OBD1 and OBD2 Problems

- 8.1. Common OBD2 Problems

- 8.2. Common OBD1 Problems

- 9. The Future of On-Board Diagnostics

- 9.1. OBD3

- 9.2. Enhanced Data and Analytics

- 9.3. Integration with ADAS

- 9.4. Cybersecurity

- 10. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs?

- 10.1. Expert Guidance

- 10.2. Comprehensive Training

- 10.3. Remote Support

- 10.4. Quality Diagnostic Tools

- 10.5. Up-to-Date Information

- FAQ: Your Questions About OBD1 and OBD2 Answered

- Q1: Can I use an OBD2 scanner on an OBD1 car with an adapter?

- Q2: Where can I find the OBD port in my car?

- Q3: What does it mean if my OBD scanner says “No Link”?

- Q4: Are all 1996 cars OBD2 compliant?

- Q5: What are the benefits of using OBD2 over OBD1?

- Q6: How do I clear a trouble code after fixing the issue?

- Q7: Can I diagnose ABS and airbag issues with an OBD2 scanner?

- Q8: What is a “Readiness Monitor,” and why is it important?

- Q9: How often should I scan my car for trouble codes?

- Q10: What is the difference between a code reader and a scan tool?

1. What is OBD and Why Does It Matter?

OBD stands for On-Board Diagnostics, and it’s a system that monitors the performance of your vehicle’s engine and other critical components. Why does it matter? Because it helps identify issues early, ensuring efficient repairs and preventing more significant problems down the road.

1.1. The Evolution of OBD Systems

The automotive industry has seen a significant evolution in on-board diagnostic systems. According to a study by the University of California, Berkeley, early OBD systems, known as OBD1, lacked standardization, making it difficult to diagnose issues across different makes and models. OBD2, introduced in the mid-1990s, brought much-needed standardization, improving diagnostic accuracy and efficiency. The California Air Resources Board (CARB) mandated OBD2 in 1996 for all new vehicles sold in California, setting a precedent for nationwide adoption.

1.2. OBD1: The Early Days

OBD1 was used in vehicles manufactured before the mid-1990s. However, the exact implementation varied significantly between manufacturers. This lack of standardization meant that diagnostic tools and codes were often specific to each make and model.

1.3. OBD2: The Standardized System

OBD2 is a standardized system introduced in the mid-1990s and mandated in 1996 for all new vehicles sold in the United States. It provides a universal interface and diagnostic codes, making it easier to diagnose and repair vehicles regardless of the manufacturer. According to the EPA, OBD2 systems monitor a wide range of vehicle parameters, including emissions, engine performance, and fuel efficiency.

2. Key Differences Between OBD1 and OBD2

Understanding the key differences between OBD1 and OBD2 is essential for accurate diagnostics. OBD2 offers significant improvements over OBD1 in terms of standardization, the amount of data available, and the ease of accessing that data.

2.1. Standardization

One of the most significant differences is standardization. OBD1 systems varied widely between manufacturers, while OBD2 systems adhere to a strict set of standards. According to a report by the Society of Automotive Engineers (SAE), OBD2 compliance ensures that all vehicles have a standardized diagnostic port (SAE J1962), a common set of diagnostic trouble codes (DTCs), and a uniform communication protocol.

2.2. Diagnostic Trouble Codes (DTCs)

OBD2 provides standardized DTCs, making it easier to identify problems. These codes are consistent across different makes and models, allowing technicians to quickly diagnose issues. OBD1 systems often used proprietary codes that required specific diagnostic tools and information.

2.3. Data Availability

OBD2 systems provide a wealth of data compared to OBD1. They monitor a wide range of parameters, including engine performance, emissions, and fuel efficiency. This data can be accessed using a standard scan tool, providing technicians with comprehensive information for diagnosing problems.

2.4. Connector Type and Location

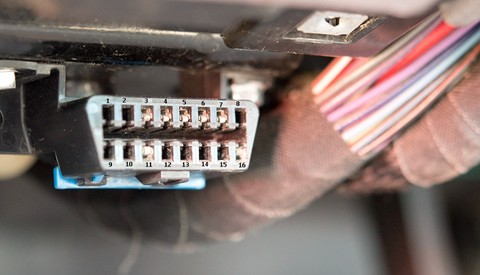

OBD2 uses a standardized 16-pin Data Link Connector (DLC), typically located under the dashboard on the driver’s side. OBD1 connectors varied in shape and location, often requiring adapters or specific tools.

2.5. Communication Protocols

OBD2 systems use standardized communication protocols such as Controller Area Network (CAN), ISO 9141-2, and SAE J1850. OBD1 systems used a variety of proprietary protocols, making it difficult to communicate with the vehicle’s computer without the correct tool.

3. How to Determine If Your Car Has OBD1 or OBD2

Determining whether your car has OBD1 or OBD2 is straightforward. The easiest way is to check the vehicle’s manufacturing date. However, there are other methods to confirm the type of system your car uses.

3.1. Check the Manufacturing Date

- OBD1: Typically found in vehicles manufactured before 1996.

- OBD2: Mandated for all vehicles sold in the US from 1996 onwards.

While this is a general rule, some vehicles manufactured in 1995 may have OBD2 systems. Always double-check using the other methods described below.

3.2. Locate the Diagnostic Connector

- OBD2: Look for a 16-pin Data Link Connector (DLC) typically located under the dashboard on the driver’s side. The connector is trapezoidal in shape.

- OBD1: OBD1 connectors vary in shape and location. They may be found under the dashboard, in the engine bay, or even behind the fuse box. They often have fewer than 16 pins and are not trapezoidal.

Standard OBD2 Port

Standard OBD2 Port

3.3. Check the Vehicle’s Emissions Sticker

Look for a sticker under the hood or on one of the front door pillars. This sticker often indicates whether the vehicle is OBD2 compliant. It may state “OBD II Certified” or similar language.

3.4. Consult Your Vehicle’s Manual

Your vehicle’s owner’s manual should provide information about the OBD system used in your car. Check the section on diagnostics or emissions control for details.

3.5. Use an OBD Diagnostic Tool

If you’re still unsure, you can use an OBD diagnostic tool to check. Plug an OBD2 scanner into the diagnostic port. If the scanner connects and retrieves data, your car is likely OBD2 compliant. If it doesn’t connect, your car may have an OBD1 system or a non-standard OBD2 implementation.

4. Understanding OBD1 Systems in Detail

OBD1 systems were diverse and manufacturer-specific. Understanding their characteristics can help you diagnose and repair older vehicles.

4.1. Manufacturer-Specific Codes

OBD1 systems used manufacturer-specific diagnostic trouble codes (DTCs). This meant that a code for a faulty oxygen sensor on a Ford would be different from the code for the same issue on a GM vehicle. Technicians needed access to specific code charts and diagnostic procedures for each make and model.

4.2. Location of Diagnostic Port

The location of the diagnostic port varied widely. Some manufacturers placed it under the dashboard, while others located it in the engine bay. The shape and number of pins also differed, requiring a variety of adapters to connect diagnostic tools.

4.3. Diagnostic Procedures

Diagnostic procedures for OBD1 systems were often more complex than those for OBD2. Technicians had to use specialized tools and follow specific steps outlined in the vehicle’s service manual. Some systems required the use of analog voltmeters or oscilloscopes to diagnose problems.

4.4. Examples of OBD1 Systems

- GM ALDL (Assembly Line Diagnostic Link): Used in GM vehicles from the early 1980s to the mid-1990s. It required a special cable and software to read the diagnostic codes.

- Ford EEC-IV (Electronic Engine Control): Used in Ford vehicles from the early 1980s to the mid-1990s. It used a Self-Test Output (STO) connector to retrieve diagnostic codes.

- Toyota: Toyota OBD1 systems varied, with some using a 22-pin connector located in the engine bay.

4.5. Adapters for OBD1 Systems

Due to the variety of OBD1 connectors, adapters are often needed to connect modern scan tools. These adapters allow you to interface with the vehicle’s computer and retrieve diagnostic data.

Toyota 22 Pin OBD Port

Toyota 22 Pin OBD Port

5. Exploring OBD2 Systems in Detail

OBD2 systems brought standardization and enhanced diagnostic capabilities. Understanding their features can help you effectively diagnose and repair modern vehicles.

5.1. Standardized DTCs

OBD2 uses standardized Diagnostic Trouble Codes (DTCs) defined by SAE J2012. These codes are consistent across different makes and models, making it easier to identify problems. DTCs are five-character codes that provide information about the fault.

5.2. PID (Parameter Identification) Data

OBD2 systems provide access to a wide range of Parameter Identification (PID) data. PIDs are real-time data values that represent various engine and vehicle parameters, such as engine speed, coolant temperature, and oxygen sensor readings.

5.3. Freeze Frame Data

When a DTC is set, the OBD2 system stores Freeze Frame data. This data captures the values of various PIDs at the moment the fault occurred. Freeze Frame data can help technicians understand the conditions that led to the problem.

5.4. Readiness Monitors

OBD2 systems use Readiness Monitors to indicate whether various emission-related systems have been tested and are functioning correctly. These monitors help ensure that the vehicle is meeting emission standards.

5.5. Communication Protocols

OBD2 systems use standardized communication protocols, including:

- CAN (Controller Area Network): The most common protocol used in modern vehicles.

- ISO 9141-2: Used in many European and Asian vehicles.

- SAE J1850 VPW (Variable Pulse Width Modulation): Used in many GM vehicles.

- SAE J1850 PWM (Pulse Width Modulation): Used in many Ford vehicles.

5.6. Diagnostic Tools for OBD2

A wide range of diagnostic tools are available for OBD2 systems, from basic code readers to advanced scan tools. These tools allow you to read DTCs, view PID data, and perform diagnostic tests.

6. Choosing the Right Diagnostic Tool

Selecting the right diagnostic tool is crucial for efficient and accurate repairs. Consider the following factors when choosing a tool.

6.1. Compatibility

Ensure that the tool is compatible with the OBD system used in your vehicle. If you have an OBD1 vehicle, you’ll need a tool that supports OBD1 protocols and may require adapters. For OBD2 vehicles, choose a tool that supports the communication protocols used by your car.

6.2. Features

Consider the features you need. Basic code readers can read and clear DTCs, while advanced scan tools offer additional capabilities such as PID data, Freeze Frame data, and bi-directional control.

6.3. Ease of Use

Choose a tool that is easy to use and has a clear, intuitive interface. A user-friendly tool can save you time and frustration.

6.4. Updates

Ensure that the tool can be updated with the latest software and diagnostic information. Regular updates are essential to keep the tool accurate and compatible with new vehicles.

6.5. Cost

Diagnostic tools range in price from basic code readers to high-end scan tools. Consider your budget and the features you need when choosing a tool.

7. Step-by-Step Guide to Diagnosing Problems with OBD1 and OBD2

Diagnosing problems with OBD1 and OBD2 systems involves similar steps, but the tools and procedures may differ.

7.1. Diagnosing Problems with OBD2

- Connect the Scan Tool: Plug the OBD2 scan tool into the 16-pin DLC.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Read DTCs: Use the scan tool to read Diagnostic Trouble Codes (DTCs).

- Research DTCs: Look up the DTCs in a repair manual or online database to understand the possible causes of the problem.

- View Freeze Frame Data: Examine the Freeze Frame data to understand the conditions that led to the fault.

- Check Related Components: Inspect the components and systems related to the DTC.

- Test Components: Use a multimeter, oscilloscope, or other diagnostic tools to test the components.

- Repair or Replace Faulty Components: Repair or replace any faulty components.

- Clear DTCs: Clear the DTCs using the scan tool.

- Test Drive the Vehicle: Test drive the vehicle to ensure that the problem is resolved.

- Verify Readiness Monitors: Check the Readiness Monitors to ensure that all emission-related systems have been tested and are functioning correctly.

7.2. Diagnosing Problems with OBD1

- Connect the Scan Tool: Connect the OBD1 scan tool to the diagnostic port using the appropriate adapter.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Retrieve DTCs: Use the scan tool to retrieve Diagnostic Trouble Codes (DTCs). The procedure for retrieving codes varies depending on the manufacturer and system.

- Research DTCs: Look up the DTCs in a repair manual or code chart specific to the vehicle’s make and model.

- Check Related Components: Inspect the components and systems related to the DTC.

- Test Components: Use a multimeter, oscilloscope, or other diagnostic tools to test the components.

- Repair or Replace Faulty Components: Repair or replace any faulty components.

- Clear DTCs: Clear the DTCs using the scan tool or by disconnecting the battery for a period of time.

- Test Drive the Vehicle: Test drive the vehicle to ensure that the problem is resolved.

8. Common OBD1 and OBD2 Problems

Both OBD1 and OBD2 systems can encounter various problems. Knowing the common issues can help you diagnose and repair them more efficiently.

8.1. Common OBD2 Problems

- P0171 – System Too Lean (Bank 1): Indicates that the engine is running lean, which can be caused by vacuum leaks, faulty oxygen sensors, or fuel delivery problems.

- P0300 – Random Misfire Detected: Indicates that the engine is misfiring, which can be caused by faulty spark plugs, ignition coils, or fuel injectors.

- P0420 – Catalyst System Efficiency Below Threshold (Bank 1): Indicates that the catalytic converter is not functioning efficiently.

- P0442 – Evaporative Emission Control System Leak Detected (Small Leak): Indicates that there is a small leak in the evaporative emission control system.

- P0505 – Idle Control System Malfunction: Indicates that there is a problem with the idle control system.

8.2. Common OBD1 Problems

- GM ALDL Code 43 – Electronic Spark Control (ESC) Circuit: Indicates a problem with the ESC circuit, which can affect ignition timing and engine performance.

- Ford EEC-IV Code 11 – System Pass: Indicates that the system has passed the self-test. This code is normal and does not indicate a problem.

- Ford EEC-IV Code 41 – Oxygen Sensor (Bank 1) Indicates Lean: Indicates that the oxygen sensor is detecting a lean condition.

- Toyota Code 25 – Lean Air-Fuel Ratio: Indicates that the air-fuel ratio is too lean.

- Toyota Code 52 – Knock Sensor Circuit Malfunction: Indicates that there is a problem with the knock sensor circuit.

9. The Future of On-Board Diagnostics

On-board diagnostics continue to evolve with advancements in automotive technology. Future systems will likely incorporate more sophisticated monitoring capabilities and integration with telematics and cloud-based services.

9.1. OBD3

While not yet widely implemented, OBD3 is a proposed standard that would add wireless communication capabilities to on-board diagnostic systems. This would allow vehicles to automatically report emission-related problems to regulatory agencies, facilitating quicker repairs and reducing pollution.

9.2. Enhanced Data and Analytics

Future OBD systems will likely provide more detailed data and analytics, allowing technicians to diagnose problems more accurately and efficiently. This data could be used to predict maintenance needs and prevent breakdowns.

9.3. Integration with ADAS

On-board diagnostics will likely become more integrated with Advanced Driver Assistance Systems (ADAS). This integration could allow the vehicle to detect and diagnose problems with ADAS components, such as sensors and cameras.

9.4. Cybersecurity

As vehicles become more connected, cybersecurity will become an increasingly important consideration for on-board diagnostic systems. Future systems will need to be protected from cyberattacks that could compromise vehicle safety and performance.

10. Why Choose CAR-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs?

At CAR-DIAGNOSTIC-TOOL.EDU.VN, we understand the challenges technicians face when diagnosing and repairing vehicles. That’s why we offer a comprehensive range of services and resources to help you succeed.

10.1. Expert Guidance

Our team of experienced automotive technicians and trainers are here to provide you with expert guidance and support. Whether you’re troubleshooting a complex problem or need help using a diagnostic tool, we’re here to help.

10.2. Comprehensive Training

We offer comprehensive training programs designed to enhance your diagnostic skills and keep you up-to-date with the latest technologies. Our training covers a wide range of topics, including OBD1 and OBD2 systems, diagnostic procedures, and advanced troubleshooting techniques.

10.3. Remote Support

Our remote support services provide you with real-time assistance when you need it most. Using remote diagnostic tools, we can connect to your vehicle and help you diagnose problems, perform tests, and program components.

10.4. Quality Diagnostic Tools

We offer a wide range of high-quality diagnostic tools from leading manufacturers. Our tools are designed to be accurate, reliable, and easy to use.

10.5. Up-to-Date Information

We provide you with the latest diagnostic information, including DTC definitions, wiring diagrams, and repair procedures. Our resources are constantly updated to ensure that you have the most accurate and current information available.

FAQ: Your Questions About OBD1 and OBD2 Answered

Navigating the world of OBD1 and OBD2 can bring up many questions. Here are some of the most frequently asked questions to help clarify any confusion.

Q1: Can I use an OBD2 scanner on an OBD1 car with an adapter?

No, even with an adapter, an OBD2 scanner will not work on an OBD1 car. You need a scan tool specifically designed to read OBD1 protocols. Adapters only change the connector shape, not the underlying communication protocol.

Q2: Where can I find the OBD port in my car?

For OBD2 cars (1996 and newer), the port is usually located under the dashboard on the driver’s side. For OBD1 cars, the location varies; check under the dashboard, in the engine bay, or behind the fuse box.

Q3: What does it mean if my OBD scanner says “No Link”?

This usually means the scanner cannot communicate with the car’s computer. Check the connection, ensure the ignition is on, and verify the scanner is compatible with your car’s OBD system.

Q4: Are all 1996 cars OBD2 compliant?

Yes, all cars sold in the US from 1996 onward are required to be OBD2 compliant. However, some late 1995 models might also have OBD2.

Q5: What are the benefits of using OBD2 over OBD1?

OBD2 offers standardized diagnostic trouble codes (DTCs), more data parameters, and a universal connector, making diagnostics easier and more efficient compared to the manufacturer-specific nature of OBD1.

Q6: How do I clear a trouble code after fixing the issue?

With an OBD2 scanner, you can clear the codes directly. For some OBD1 systems, you may need to disconnect the battery for a short period to reset the computer.

Q7: Can I diagnose ABS and airbag issues with an OBD2 scanner?

Basic OBD2 scanners primarily read engine and emission-related codes. Advanced scan tools are needed to diagnose ABS and airbag systems.

Q8: What is a “Readiness Monitor,” and why is it important?

Readiness Monitors indicate whether your car’s emission systems have been tested. They are important for passing emissions tests and ensuring your car meets environmental standards.

Q9: How often should I scan my car for trouble codes?

You should scan your car whenever the “Check Engine” light comes on or if you notice any performance issues. Regular checks can help catch minor problems before they become major repairs.

Q10: What is the difference between a code reader and a scan tool?

A code reader typically only reads and clears trouble codes. A scan tool offers additional features like live data streaming, freeze frame data, and advanced diagnostic tests.

Ready to take your automotive diagnostic skills to the next level? Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance, comprehensive training, and top-quality diagnostic tools. Whether you’re dealing with OBD1 or OBD2 systems, we have the solutions you need to succeed. Our team is ready to assist you with remote support and up-to-date information to ensure your repairs are accurate and efficient. Don’t wait – enhance your career and improve your diagnostic capabilities now. Contact us at +1 (641) 206-8880 or visit our website CAR-DIAGNOSTIC-TOOL.EDU.VN. Our office is located at 1100 Congress Ave, Austin, TX 78701, United States. Let CAR-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in automotive diagnostics.