Global OBD2 contains data in various formats, including hexadecimal, ASCII, and numerical, to facilitate vehicle diagnostics and performance monitoring. CAR-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive tools and resources for interpreting these formats, ensuring accurate vehicle maintenance and repair, coupled with real-time data analysis and troubleshooting guidance. Enhance your skills through our technician training programs and access expert remote support for seamless vehicle diagnostics and repair.

Contents

- 1. Understanding Global OBD2 Data Formats

- 1.1 The Role of Global OBD2 in Vehicle Diagnostics

- 1.2 Key Data Formats in Global OBD2

- 1.3 Diagnostic Trouble Codes (DTCs): Hexadecimal Format

- 1.4 Parameter IDs (PIDs): A Mix of Formats

- 1.5 Vehicle Identification Number (VIN): ASCII Format

- 1.6 Real-time Sensor Data: Numerical Format

- 1.7 Utilizing CAR-DIAGNOSTIC-TOOL.EDU.VN for Data Interpretation

- 1.8 Importance of Staying Updated

- 1.9 Real-World Examples

- 2. Decoding Hexadecimal Data in Global OBD2

- 2.1 Hexadecimal Basics

- 2.2 Why Hexadecimal in OBD2?

- 2.3 Decoding Diagnostic Trouble Codes (DTCs)

- 2.4 Interpreting Parameter IDs (PIDs)

- 2.5 Converting Hexadecimal to Decimal

- 2.6 Using Diagnostic Tools for Hexadecimal Interpretation

- 2.7 Real-World Examples

- 2.8 Advanced Techniques for Hexadecimal Decoding

- 2.9 The Value of Expertise

- 3. Understanding ASCII Data in Global OBD2

- 3.1 ASCII Basics

- 3.2 Why ASCII in OBD2?

- 3.3 Vehicle Identification Number (VIN)

- 3.4 Diagnostic Messages and Descriptions

- 3.5 Converting ASCII to Hexadecimal

- 3.6 Using Diagnostic Tools for ASCII Interpretation

- 3.7 Real-World Examples

- 3.8 Advanced Applications of ASCII Data

- 3.9 Importance of Accurate Data Interpretation

- 4. Numerical Data and Its Significance in Global OBD2

- 4.1 Understanding Numerical Data

- 4.2 Scaling and Conversion Factors

- 4.3 Real-Time Sensor Data

- 4.4 Using Diagnostic Tools for Numerical Interpretation

- 4.5 Real-World Examples

- 4.6 Data Validation Techniques

- 4.7 The Importance of Calibration

- 5. Global OBD2 Protocols and Data Transmission

- 5.1 Key OBD2 Protocols

- 5.2 Data Request and Response

- 5.3 Understanding CAN Bus Communication

- 5.4 Using Diagnostic Tools for Protocol Analysis

- 5.5 Real-World Examples

- 5.6 Security Considerations

- 6. Common Challenges and Solutions in Interpreting Global OBD2 Data

- 6.1 Solutions for Common Challenges

- 6.2 Overcoming Inconsistent Data Formats

- 6.3 Addressing Proprietary PIDs

- 6.4 Managing Communication Errors

- 6.5 Coping with Data Overload

- 6.6 The Role of AI and Machine Learning

- 7. Tools and Resources for Global OBD2 Data Interpretation

- 7.1 Diagnostic Scanners

- 7.2 PC-Based Diagnostic Software

- 7.3 Mobile Apps

- 7.4 Online Resources

- 7.5 Training Programs

- 7.6 CAR-DIAGNOSTIC-TOOL.EDU.VN Resources

- 7.7 Selecting the Right Tools

1. Understanding Global OBD2 Data Formats

Global On-Board Diagnostics II (OBD2) systems are pivotal in modern automotive diagnostics, providing access to a wealth of vehicle data. But what format does global OBD2 contain some data in? Understanding how data is structured within the global OBD2 system is essential for effective diagnostics and repair. This section dives into the various formats used, offering a comprehensive guide for technicians and automotive enthusiasts alike.

1.1 The Role of Global OBD2 in Vehicle Diagnostics

Global OBD2, standardized across most vehicles, serves as a window into the vehicle’s internal operations. According to a study by the Society of Automotive Engineers (SAE), OBD2 systems are designed to monitor critical engine and emissions components, reporting issues through Diagnostic Trouble Codes (DTCs) and real-time parameter data. This standardization facilitates easier diagnostics, regardless of vehicle make or model, a point emphasized in a 2022 report by the Environmental Protection Agency (EPA).

1.2 Key Data Formats in Global OBD2

OBD2 data is not presented in a single, uniform format. Instead, it employs a variety of formats tailored to the type of information being conveyed. Key data formats include:

- Hexadecimal: Used extensively for representing DTCs, Parameter IDs (PIDs), and control byte values.

- ASCII: Primarily used for Vehicle Identification Numbers (VINs) and text-based diagnostic messages.

- Numerical: Commonly used for real-time sensor data such as engine speed (RPM), vehicle speed, and temperature readings.

1.3 Diagnostic Trouble Codes (DTCs): Hexadecimal Format

DTCs are arguably the most recognizable component of the OBD2 system. They are five-character codes, such as P0300 (random misfire detected), that identify specific faults detected by the vehicle’s onboard computer. According to the SAE J1979 standard, DTCs are structured as follows:

- The first character indicates the system involved (e.g., P for Powertrain, B for Body, C for Chassis, and U for Network).

- The second character specifies whether the code is generic (0) or manufacturer-specific (1).

- The remaining three characters are hexadecimal values that pinpoint the exact nature of the fault.

For instance, the code P0101 translates to a generic (0) powertrain (P) fault, with “0101” indicating an issue with the Mass Air Flow (MAF) sensor range or performance.

1.4 Parameter IDs (PIDs): A Mix of Formats

Parameter IDs (PIDs) are codes used to request specific data parameters from the vehicle’s computer. As detailed in the ISO 15031-5 standard, PIDs are typically represented in hexadecimal format. However, the data returned in response to a PID request can be in various formats, including numerical values for sensor readings and bit-encoded data for system status flags.

For example, PID 0x0C requests engine RPM, with the response being a numerical value that needs to be scaled according to a predefined formula to obtain the actual RPM. This scaling factor is usually specified in the vehicle’s service manual or within OBD2 diagnostic software.

1.5 Vehicle Identification Number (VIN): ASCII Format

The Vehicle Identification Number (VIN) is a unique identifier for each vehicle, akin to a fingerprint. As outlined in the ISO 3779 standard, the VIN is a 17-character code composed of letters and numbers, stored in ASCII format. This format allows for easy readability and transmission of the VIN, which is essential for vehicle registration, insurance, and diagnostic purposes.

For example, a typical VIN might look like this: “1G1ZD3795UR200000”. Each segment of the VIN provides specific information about the vehicle, such as the manufacturer, model, and production year.

1.6 Real-time Sensor Data: Numerical Format

One of the most valuable features of OBD2 is its ability to provide real-time sensor data, allowing technicians to monitor vehicle performance under various conditions. This data is typically transmitted as numerical values, representing measurements such as:

- Engine Speed (RPM): Revolutions per minute of the engine crankshaft.

- Vehicle Speed: Current speed of the vehicle in miles per hour (MPH) or kilometers per hour (km/h).

- Coolant Temperature: Temperature of the engine coolant in degrees Celsius or Fahrenheit.

- Oxygen Sensor Readings: Voltage or current values indicating the oxygen content in the exhaust gases.

These numerical values often require scaling and conversion to obtain meaningful units, as specified in the vehicle’s service manual or OBD2 diagnostic software. For example, a coolant temperature reading might be transmitted as a raw value of 150, which, after applying the appropriate scaling factor, translates to 80 degrees Celsius.

1.7 Utilizing CAR-DIAGNOSTIC-TOOL.EDU.VN for Data Interpretation

Interpreting the diverse data formats within OBD2 can be challenging, especially for those new to vehicle diagnostics. CAR-DIAGNOSTIC-TOOL.EDU.VN provides a suite of resources to simplify this process:

- Diagnostic Software: Our diagnostic software tools automatically decode OBD2 data, presenting it in an easy-to-understand format with descriptions and units.

- Knowledge Base: Access a comprehensive library of articles, tutorials, and reference materials covering OBD2 data formats, DTC definitions, and PID scaling factors.

- Technical Support: Our team of experienced technicians is available to provide expert guidance and support, helping you troubleshoot diagnostic issues and interpret OBD2 data accurately.

- Training Programs: Enhance your diagnostic skills with our hands-on training programs, covering OBD2 data analysis, fault diagnosis, and repair procedures.

By leveraging these resources, technicians can confidently navigate the complexities of OBD2 data formats, enabling faster and more accurate vehicle diagnostics.

1.8 Importance of Staying Updated

The OBD2 standard is continuously evolving, with new PIDs, DTCs, and data formats being introduced to support advanced vehicle technologies. Staying updated with the latest developments is crucial for effective diagnostics.

CAR-DIAGNOSTIC-TOOL.EDU.VN is committed to providing the most current and accurate information on OBD2 data formats. Our team regularly updates our software, knowledge base, and training programs to reflect the latest industry standards and vehicle technologies. By staying connected with CAR-DIAGNOSTIC-TOOL.EDU.VN, you can ensure that you have the knowledge and tools necessary to diagnose and repair modern vehicles effectively.

1.9 Real-World Examples

Let’s consider some practical examples of how OBD2 data formats are used in vehicle diagnostics:

Example 1: Diagnosing a Misfire

A vehicle’s malfunction indicator light (MIL) illuminates, indicating a potential issue. Using an OBD2 scanner, the technician retrieves the DTC P0301, which translates to “Cylinder 1 Misfire Detected”. The technician then uses real-time data to monitor engine RPM, oxygen sensor readings, and fuel trim values for cylinder 1. By analyzing these parameters, the technician can identify the root cause of the misfire, such as a faulty spark plug, fuel injector, or ignition coil.

Example 2: Monitoring Engine Performance

A vehicle owner wants to monitor their vehicle’s performance and fuel efficiency. Using an OBD2 dongle and a smartphone app, they can access real-time data such as engine RPM, vehicle speed, and fuel consumption. By analyzing this data, they can identify driving habits that negatively impact fuel efficiency and make adjustments to improve their MPG.

These examples illustrate the power and versatility of OBD2 data in vehicle diagnostics and performance monitoring. By understanding the various data formats and utilizing the resources provided by CAR-DIAGNOSTIC-TOOL.EDU.VN, technicians and vehicle owners can unlock valuable insights into their vehicles’ health and performance.

2. Decoding Hexadecimal Data in Global OBD2

One prevalent format is hexadecimal, which might seem daunting at first glance. However, understanding hexadecimal data is essential for interpreting DTCs, PIDs, and other critical information. Let’s explore how to decode hexadecimal data within global OBD2, offering practical insights for technicians and enthusiasts.

2.1 Hexadecimal Basics

Hexadecimal, often abbreviated as “hex,” is a base-16 numbering system. Unlike the decimal system (base-10) we use daily, which uses digits 0-9, hexadecimal uses 16 symbols: 0-9 and A-F, where A=10, B=11, C=12, D=13, E=14, and F=15. Each hexadecimal digit represents four bits (a “nibble”), making it convenient for representing binary data. A byte (8 bits) can be represented by two hexadecimal digits.

2.2 Why Hexadecimal in OBD2?

Hexadecimal is used extensively in OBD2 for several reasons:

- Compact Representation: It allows for compact representation of binary data, reducing the amount of data that needs to be transmitted and stored.

- Human-Readable: While not as intuitive as decimal, hexadecimal is more human-readable than binary, making it easier for technicians to interpret data.

- Standardization: The use of hexadecimal in OBD2 is standardized across different vehicle makes and models, ensuring consistency and compatibility.

2.3 Decoding Diagnostic Trouble Codes (DTCs)

As mentioned earlier, DTCs are five-character codes that identify specific faults detected by the vehicle’s onboard computer. The last three characters of a DTC are hexadecimal values that pinpoint the exact nature of the fault.

For example, consider the DTC P0420, which indicates “Catalyst System Efficiency Below Threshold (Bank 1)”. The hexadecimal value “420” provides specific information about the nature of the catalyst system fault. While the specific meaning of “420” may vary depending on the vehicle make and model, it serves as a unique identifier for this particular fault.

2.4 Interpreting Parameter IDs (PIDs)

Parameter IDs (PIDs) are codes used to request specific data parameters from the vehicle’s computer. PIDs are typically represented in hexadecimal format, with each PID corresponding to a specific data parameter.

For example, PID 0x0C requests engine RPM, while PID 0x0D requests vehicle speed. The hexadecimal values “0C” and “0D” serve as unique identifiers for these data parameters.

2.5 Converting Hexadecimal to Decimal

In some cases, it may be necessary to convert hexadecimal values to decimal values for further analysis or calculations. The conversion process involves multiplying each hexadecimal digit by its corresponding power of 16 and then summing the results.

For example, let’s convert the hexadecimal value 0x420 to decimal:

(4 * 16^2) + (2 * 16^1) + (0 * 16^0) = (4 * 256) + (2 * 16) + (0 * 1) = 1024 + 32 + 0 = 1056

Therefore, the hexadecimal value 0x420 is equivalent to the decimal value 1056.

2.6 Using Diagnostic Tools for Hexadecimal Interpretation

Modern diagnostic tools often automate the process of interpreting hexadecimal data, presenting it in a human-readable format with descriptions and units. These tools typically include features such as:

- DTC Lookup: Automatically decodes DTCs, providing descriptions of the fault and potential causes.

- PID Display: Displays real-time data parameters in a user-friendly format, with units and scaling factors applied.

- Hexadecimal Conversion: Converts hexadecimal values to decimal values for further analysis.

By utilizing these tools, technicians can quickly and accurately interpret hexadecimal data, enabling faster and more effective vehicle diagnostics.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides a range of diagnostic tools that simplify the process of hexadecimal interpretation. Our tools are designed to be user-friendly and intuitive, allowing technicians to quickly access the information they need to diagnose and repair vehicles effectively.

2.7 Real-World Examples

Let’s consider some practical examples of how hexadecimal data is used in vehicle diagnostics:

Example 1: Diagnosing a Faulty Oxygen Sensor

A technician retrieves the DTC P0131, which indicates “O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1)”. The technician then uses real-time data to monitor the oxygen sensor voltage, which is displayed in hexadecimal format. By analyzing the hexadecimal values, the technician can determine if the sensor voltage is within the normal range or if it is too low, indicating a potential issue with the sensor.

Example 2: Monitoring Fuel Trim Values

A vehicle owner wants to monitor their vehicle’s fuel trim values to identify potential issues with the fuel system. Using an OBD2 dongle and a smartphone app, they can access real-time data such as short-term fuel trim (STFT) and long-term fuel trim (LTFT), which are displayed in hexadecimal format. By analyzing the hexadecimal values, they can determine if the fuel system is running lean or rich, indicating potential issues with the fuel injectors, mass airflow sensor, or oxygen sensors.

2.8 Advanced Techniques for Hexadecimal Decoding

For advanced users and vehicle diagnostic specialists, a deeper understanding of hexadecimal decoding can unlock even more insights into vehicle performance and potential issues. Here are some advanced techniques:

- Bitmasking: In some cases, hexadecimal values may represent multiple pieces of information encoded using bitmasking. Bitmasking involves using binary AND operations to extract specific bits from the hexadecimal value, each representing a different status or setting. Understanding bitmasking can allow you to decode complex data parameters.

- Lookup Tables: Vehicle manufacturers often use lookup tables to translate hexadecimal values into specific meanings. These lookup tables may be found in service manuals, technical documentation, or online resources. By consulting these tables, you can gain a deeper understanding of the data being represented.

- Custom Decoding: For certain advanced diagnostics or reverse engineering tasks, you may need to develop custom decoding algorithms to interpret hexadecimal data. This may involve analyzing the data patterns, consulting technical specifications, and using programming languages to create custom decoding tools.

2.9 The Value of Expertise

While understanding hexadecimal data is crucial, it’s equally important to recognize the value of expertise in vehicle diagnostics. Experienced technicians possess the knowledge, skills, and intuition to interpret complex data patterns, identify subtle issues, and make informed decisions.

CAR-DIAGNOSTIC-TOOL.EDU.VN offers access to a network of experienced technicians who can provide expert guidance and support. Whether you’re facing a challenging diagnostic issue or simply need a second opinion, our team is here to help.

3. Understanding ASCII Data in Global OBD2

While hexadecimal and numerical formats are prominent in global OBD2, ASCII (American Standard Code for Information Interchange) also plays a crucial role. ASCII is a character encoding standard for electronic communication. Understanding how ASCII data is used in global OBD2 is essential for accessing certain types of vehicle information and performing advanced diagnostic procedures.

3.1 ASCII Basics

ASCII is a character encoding standard that assigns a unique numerical value to each character, including letters, numbers, punctuation marks, and control characters. The standard ASCII character set includes 128 characters, with values ranging from 0 to 127. Extended ASCII character sets include additional characters, such as accented letters and symbols.

3.2 Why ASCII in OBD2?

ASCII is used in OBD2 for several reasons:

- Human-Readable: ASCII data is human-readable, making it easy for technicians to interpret and understand.

- Text-Based Information: ASCII is ideal for representing text-based information, such as vehicle identification numbers (VINs), diagnostic messages, and descriptions.

- Standardization: The use of ASCII in OBD2 is standardized across different vehicle makes and models, ensuring consistency and compatibility.

3.3 Vehicle Identification Number (VIN)

As mentioned earlier, the VIN is a unique identifier for each vehicle, akin to a fingerprint. The VIN is a 17-character code composed of letters and numbers, stored in ASCII format. This format allows for easy readability and transmission of the VIN, which is essential for vehicle registration, insurance, and diagnostic purposes.

Diagnostic tools use ASCII-encoded VINs to accurately identify vehicles, access relevant technical specifications, and perform diagnostic procedures. Ensuring accurate VIN retrieval is critical for reliable diagnostics.

3.4 Diagnostic Messages and Descriptions

In addition to the VIN, ASCII is used to represent diagnostic messages and descriptions. These messages provide additional information about the nature of a fault or issue, supplementing the information provided by DTCs.

For example, a diagnostic message might provide additional details about the conditions under which a fault occurred, such as the engine speed, load, and temperature. This information can be invaluable in troubleshooting complex diagnostic issues.

3.5 Converting ASCII to Hexadecimal

In some cases, it may be necessary to convert ASCII data to hexadecimal values for further analysis or manipulation. Each ASCII character has a corresponding hexadecimal value, which can be obtained from an ASCII table.

For example, the ASCII character “A” has a hexadecimal value of 0x41, while the ASCII character “1” has a hexadecimal value of 0x31.

3.6 Using Diagnostic Tools for ASCII Interpretation

Modern diagnostic tools often automate the process of interpreting ASCII data, presenting it in a human-readable format with descriptions and units. These tools typically include features such as:

- VIN Decoding: Automatically decodes the VIN, providing information about the vehicle make, model, year, and specifications.

- Message Display: Displays diagnostic messages and descriptions in a user-friendly format, with clear and concise language.

- ASCII Conversion: Converts ASCII data to hexadecimal values for further analysis.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides diagnostic tools that simplify the process of ASCII interpretation. Our tools are designed to be user-friendly and intuitive, allowing technicians to quickly access the information they need to diagnose and repair vehicles effectively.

3.7 Real-World Examples

Let’s consider some practical examples of how ASCII data is used in vehicle diagnostics:

Example 1: Verifying the VIN

A technician retrieves the VIN from a vehicle using an OBD2 scanner. The VIN is displayed in ASCII format. The technician then compares the retrieved VIN with the VIN on the vehicle’s dashboard or doorjamb to verify that they match. This ensures that the technician is working on the correct vehicle and accessing the correct diagnostic information.

Example 2: Interpreting a Diagnostic Message

A technician retrieves a DTC from a vehicle, along with an accompanying diagnostic message. The diagnostic message is displayed in ASCII format and provides additional information about the nature of the fault. The technician reads the diagnostic message carefully to gain a better understanding of the issue and to identify potential causes.

3.8 Advanced Applications of ASCII Data

Beyond basic diagnostics, ASCII data is instrumental in advanced applications like:

- Custom Parameter Identification: ASCII strings are sometimes used to define custom PIDs or commands in manufacturer-specific diagnostic protocols. Understanding these custom commands is vital for advanced diagnostics.

- Data Logging and Analysis: When logging OBD2 data, ASCII-encoded fields can provide crucial context, such as timestamps, vehicle IDs, and event descriptions. Analyzing these logs requires proper interpretation of ASCII data.

- Software Updates and Reprogramming: ASCII-based messages are often used during software updates and reprogramming procedures to verify data integrity, confirm device IDs, and transmit control commands.

3.9 Importance of Accurate Data Interpretation

Misinterpreting ASCII data can lead to incorrect diagnoses, improper repairs, and potential damage to the vehicle. It’s crucial to use reliable diagnostic tools, consult technical documentation, and seek expert guidance when working with ASCII data in OBD2 systems.

CAR-DIAGNOSTIC-TOOL.EDU.VN emphasizes the importance of accurate data interpretation in all of our training programs and technical resources. We provide comprehensive instruction on ASCII decoding, data validation, and best practices for vehicle diagnostics.

OBD2 multi-frame request message vehicle identification number

OBD2 multi-frame request message vehicle identification number

4. Numerical Data and Its Significance in Global OBD2

Numerical data is also a cornerstone of global OBD2 diagnostics, providing quantitative measurements of various vehicle parameters. Understanding how numerical data is formatted, scaled, and interpreted is essential for accurate diagnostics and performance analysis.

4.1 Understanding Numerical Data

Numerical data in OBD2 is typically transmitted as integer or floating-point values, representing measurements such as engine speed (RPM), vehicle speed, coolant temperature, and sensor voltages. These values may be encoded in different formats, such as binary, hexadecimal, or decimal, depending on the specific parameter and vehicle manufacturer.

4.2 Scaling and Conversion Factors

One of the key challenges in interpreting numerical data is understanding the scaling and conversion factors that must be applied to obtain meaningful units. For example, a coolant temperature reading might be transmitted as a raw value of 150, which, after applying the appropriate scaling factor, translates to 80 degrees Celsius.

Scaling and conversion factors are typically specified in the vehicle’s service manual or OBD2 diagnostic software. It’s crucial to consult these resources to ensure that you are interpreting the data correctly.

4.3 Real-Time Sensor Data

One of the most valuable features of OBD2 is its ability to provide real-time sensor data, allowing technicians to monitor vehicle performance under various conditions. This data can be used to diagnose a wide range of issues, from engine misfires to transmission problems.

Examples of real-time sensor data include:

- Engine Speed (RPM)

- Vehicle Speed

- Coolant Temperature

- Oxygen Sensor Readings

- Fuel Trim Values

- Mass Airflow (MAF)

- Throttle Position

By monitoring these parameters, technicians can gain valuable insights into the vehicle’s performance and identify potential issues before they become major problems.

4.4 Using Diagnostic Tools for Numerical Interpretation

Modern diagnostic tools often automate the process of interpreting numerical data, presenting it in a user-friendly format with units and scaling factors applied. These tools typically include features such as:

- Data Display: Displays real-time sensor data in a graphical or tabular format, with units and scaling factors clearly indicated.

- Data Logging: Logs real-time sensor data over time, allowing technicians to analyze trends and identify intermittent issues.

- Threshold Alerts: Sets threshold alerts for specific parameters, notifying technicians when a value exceeds or falls below a specified range.

4.5 Real-World Examples

Let’s consider some practical examples of how numerical data is used in vehicle diagnostics:

Example 1: Diagnosing an Overheating Engine

A technician is diagnosing an overheating engine. Using an OBD2 scanner, the technician monitors the coolant temperature in real-time. The coolant temperature is displayed as a numerical value in degrees Celsius. The technician observes that the coolant temperature is steadily rising and exceeds the normal operating range, indicating an overheating condition.

Example 2: Analyzing Fuel Trim Values

A technician is diagnosing a vehicle with poor fuel economy. Using an OBD2 scanner, the technician monitors the short-term fuel trim (STFT) and long-term fuel trim (LTFT) values in real-time. The fuel trim values are displayed as numerical percentages. The technician observes that the LTFT value is consistently positive, indicating that the engine is running lean and the fuel system is compensating by adding more fuel.

4.6 Data Validation Techniques

Ensuring the accuracy and reliability of numerical data is crucial for effective diagnostics. Here are some data validation techniques:

- Cross-Referencing: Compare readings from multiple sensors to identify discrepancies or anomalies. For instance, compare the mass airflow sensor reading with the engine RPM and throttle position to validate its accuracy.

- Range Checks: Verify that sensor readings fall within expected ranges based on vehicle specifications. Out-of-range values may indicate faulty sensors or wiring issues.

- Trend Analysis: Analyze data trends over time to identify patterns and anomalies. Sudden spikes or drops in sensor readings may indicate intermittent issues.

- Physical Inspection: Correlate sensor readings with physical inspections of the vehicle components. For example, if the coolant temperature sensor indicates an overheating condition, visually inspect the cooling system for leaks or blockages.

4.7 The Importance of Calibration

Accurate numerical data relies on properly calibrated sensors and diagnostic tools. Regularly calibrate your diagnostic equipment according to manufacturer specifications to ensure reliable readings.

CAR-DIAGNOSTIC-TOOL.EDU.VN provides calibration services for a wide range of diagnostic tools, ensuring that your equipment is always operating at peak performance.

Requesting multiple PIDs in one request

Requesting multiple PIDs in one request

5. Global OBD2 Protocols and Data Transmission

Beyond understanding the data formats, it’s crucial to grasp the protocols governing data transmission within the global OBD2 system. These protocols dictate how data is requested, transmitted, and received between the diagnostic tool and the vehicle’s onboard computer.

5.1 Key OBD2 Protocols

Several protocols are used for data transmission in OBD2, each with its own specifications and characteristics. The most common protocols include:

- ISO 9141-2

- SAE J1850 VPW

- SAE J1850 PWM

- ISO 14230-4 (KWP2000)

- ISO 15765-4 (CAN)

The CAN (Controller Area Network) protocol is the most modern and widely used protocol, particularly in vehicles manufactured after 2008. CAN offers faster data rates, improved reliability, and enhanced diagnostic capabilities compared to older protocols.

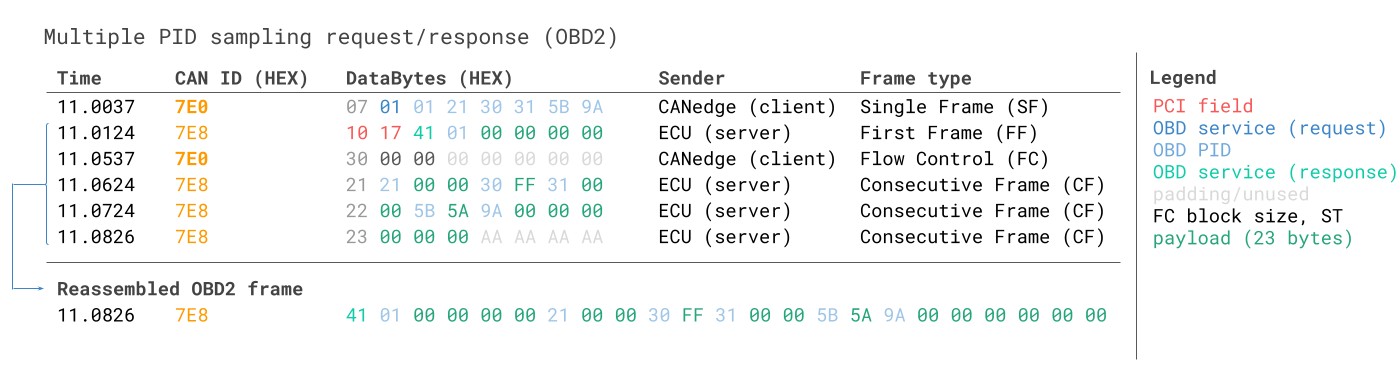

5.2 Data Request and Response

OBD2 communication follows a request-response model. The diagnostic tool sends a request to the vehicle’s onboard computer, specifying the data parameter to be retrieved. The vehicle’s computer then responds with the requested data, formatted according to the appropriate protocol and data format.

The request message typically includes the following information:

- Protocol Identifier

- Target Address (ECU Address)

- Service ID

- Parameter ID (PID)

The response message typically includes the following information:

- Protocol Identifier

- Source Address (ECU Address)

- Service ID

- Data Bytes

- Checksum

5.3 Understanding CAN Bus Communication

Since CAN is the predominant protocol in modern vehicles, it’s essential to understand CAN bus communication. CAN bus is a serial communication protocol that allows multiple electronic control units (ECUs) in a vehicle to communicate with each other without a host computer.

CAN bus communication is based on a message-oriented protocol, where each message includes an identifier, data bytes, and control bits. The identifier is used to prioritize messages and determine which ECU should receive the message. The data bytes contain the actual data being transmitted, such as sensor readings or control commands.

5.4 Using Diagnostic Tools for Protocol Analysis

Advanced diagnostic tools often include features for analyzing OBD2 protocols and data transmission. These tools typically include features such as:

- Protocol Detection: Automatically detects the OBD2 protocol being used by the vehicle.

- Data Monitoring: Monitors data transmission in real-time, displaying the request and response messages.

- Protocol Analysis: Analyzes the protocol messages, providing detailed information about the message structure, identifiers, and data bytes.

5.5 Real-World Examples

Let’s consider some practical examples of how OBD2 protocols and data transmission are used in vehicle diagnostics:

Example 1: Diagnosing a Communication Error

A technician is unable to communicate with a vehicle’s onboard computer using an OBD2 scanner. The technician suspects a communication error. Using a diagnostic tool with protocol analysis capabilities, the technician monitors the data transmission and observes that the request messages are not being acknowledged by the vehicle’s computer. This indicates a potential issue with the communication bus, wiring, or ECU.

Example 2: Reverse Engineering a Custom PID

A technician wants to retrieve data from a vehicle using a custom PID that is not supported by the standard OBD2 protocols. Using a diagnostic tool with protocol analysis capabilities, the technician monitors the data transmission and observes the request and response messages being exchanged between the diagnostic tool and the vehicle’s computer. By analyzing these messages, the technician can identify the protocol, service ID, and data bytes being used for the custom PID.

5.6 Security Considerations

Understanding OBD2 protocols is also crucial for addressing security concerns. Exploiting vulnerabilities in OBD2 communication can lead to unauthorized access to vehicle systems, potentially compromising vehicle safety and security.

CAR-DIAGNOSTIC-TOOL.EDU.VN emphasizes the importance of secure diagnostic practices in all of our training programs and technical resources. We provide guidance on implementing security measures to protect against unauthorized access and maintain the integrity of vehicle systems.

6. Common Challenges and Solutions in Interpreting Global OBD2 Data

Interpreting global OBD2 data is not always straightforward. Technicians often face challenges such as:

- Inconsistent Data Formats: Different vehicle manufacturers may use slightly different data formats or scaling factors for the same parameter.

- Proprietary PIDs: Some vehicle manufacturers use proprietary PIDs that are not documented in the standard OBD2 specifications.

- Communication Errors: Communication errors can occur due to faulty wiring, damaged connectors, or protocol incompatibilities.

- Data Overload: The sheer volume of data available through OBD2 can be overwhelming, making it difficult to identify the relevant information.

- Lack of Documentation: Documentation on specific data formats, scaling factors, and proprietary PIDs may be scarce or difficult to obtain.

6.1 Solutions for Common Challenges

Fortunately, several solutions can help overcome these challenges:

- Consult Vehicle-Specific Service Manuals: Vehicle-specific service manuals provide detailed information on data formats, scaling factors, and proprietary PIDs for specific vehicle makes and models.

- Use Advanced Diagnostic Tools: Advanced diagnostic tools often include built-in databases of data formats, scaling factors, and proprietary PIDs, simplifying the interpretation process.

- Seek Expert Guidance: Experienced technicians can provide valuable insights and guidance on interpreting complex OBD2 data, drawing on their knowledge and experience.

- Participate in Training Programs: Training programs can provide technicians with the knowledge and skills needed to interpret OBD2 data effectively.

- Use Online Resources: Online resources, such as forums and technical databases, can provide valuable information on specific data formats, scaling factors, and proprietary PIDs.

6.2 Overcoming Inconsistent Data Formats

Inconsistent data formats can be addressed by:

- Using diagnostic tools with built-in data conversion capabilities.

- Creating custom data conversion routines using programming languages such as Python or MATLAB.

- Consulting online resources and forums for information on specific data formats and scaling factors.

6.3 Addressing Proprietary PIDs

Proprietary PIDs can be addressed by:

- Reverse engineering the PID using protocol analysis tools.

- Consulting vehicle-specific service manuals or technical databases.

- Seeking guidance from experienced technicians or online forums.

6.4 Managing Communication Errors

Communication errors can be addressed by:

- Inspecting the wiring and connectors for damage or corrosion.

- Verifying the compatibility of the diagnostic tool with the vehicle’s OBD2 protocol.

- Using a known-good diagnostic tool to rule out issues with the tool itself.

6.5 Coping with Data Overload

Data overload can be addressed by:

- Using diagnostic tools with filtering and data visualization capabilities.

- Focusing on the parameters that are most relevant to the diagnostic issue.

- Logging data over time and analyzing trends to identify patterns and anomalies.

6.6 The Role of AI and Machine Learning

Emerging technologies like AI and machine learning are poised to revolutionize OBD2 data interpretation. AI-powered diagnostic tools can automatically analyze vast amounts of data, identify patterns, and provide insights that would be impossible for human technicians to detect.

CAR-DIAGNOSTIC-TOOL.EDU.VN is actively exploring the use of AI and machine learning in our diagnostic tools and training programs. We believe that these technologies will play a key role in the future of vehicle diagnostics.

7. Tools and Resources for Global OBD2 Data Interpretation

Having the right tools and resources is essential for effective global OBD2 data interpretation. Fortunately, a wide range of tools and resources are available to technicians and automotive enthusiasts.

7.1 Diagnostic Scanners

Diagnostic scanners are handheld devices that connect to a vehicle’s OBD2 port and allow technicians to retrieve DTCs, view real-time sensor data, and perform other diagnostic functions. Diagnostic scanners range from basic code readers to advanced diagnostic platforms with built-in databases, graphing capabilities, and bidirectional control functions.

7.2 PC-Based Diagnostic Software

PC-based diagnostic software offers a more powerful and versatile alternative to handheld scanners. PC-based software typically includes a wider range of features, such as data logging, graphing, and protocol analysis. PC-based software also benefits from the processing power and storage capacity of a personal computer.

7.3 Mobile Apps

Mobile apps offer a convenient and affordable way to access OBD2 data using a smartphone or tablet. Mobile apps typically connect to the vehicle’s OBD2 port via a Bluetooth or Wi-Fi adapter. Mobile apps can be used to retrieve DTCs, view real-time sensor data, and perform basic diagnostic functions.

7.4 Online Resources

Numerous online resources provide valuable information on global OBD2 data interpretation. These resources include:

- OBD2 Code Databases: Websites that provide descriptions of DTCs, potential causes, and troubleshooting tips.

- Technical Forums: Online forums where technicians can exchange information, ask questions, and share their experiences.

- Service Manuals: Online service manuals that provide detailed information on vehicle-specific data formats, scaling factors, and proprietary PIDs.

- Technical Databases: Online databases that provide technical specifications, wiring diagrams, and troubleshooting information for various vehicle makes and models.

7.5 Training Programs

Training programs offer technicians the knowledge and skills needed to interpret global OBD2 data effectively. Training programs typically cover topics such as:

- OBD2 Protocols and Standards

- Data Formats and Scaling Factors

- Diagnostic Strategies

- Troubleshooting Techniques

- Use of Diagnostic Tools

7.6 CAR-DIAGNOSTIC-TOOL.EDU.VN Resources

CAR-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive suite of tools and resources for global OBD2 data interpretation, including:

- Diagnostic Software: User-friendly diagnostic software with built-in databases, graphing capabilities, and bidirectional control functions.

- Online Resources: A vast library of technical articles, troubleshooting guides, and online forums.

- Training Programs: Hands-on training programs taught by experienced instructors.

- Technical Support: Expert technical support available via phone, email, or online chat.

7.7 Selecting the Right Tools

Choosing the right tools depends on your specific needs and budget. Consider the following factors:

- Vehicle Coverage: Ensure that the tool supports the vehicle makes and models you work on.

- Features: Select a tool with the features you need, such as data logging, graphing, and bidirectional control.

- Ease of Use: Choose a tool that is easy to use and navigate, with a user-friendly interface.

- Cost: Balance the cost of the tool with its features and capabilities.

- Support: Select a tool from a reputable vendor with reliable technical support.

By carefully considering these factors, you can select the right tools and resources to effectively interpret global OBD2 data and diagnose vehicle issues.

![CAN