The Land Rover Range Rover 4.6 Hse Obd2 Port Location is typically found beneath the dashboard on the driver’s side. CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive guides and diagnostic tools to help you locate and utilize this port effectively, ensuring accurate vehicle diagnostics and efficient repairs. Discover the ease of pinpointing your OBD2 port with our detailed instructions, supported by remote assistance and technician training for optimal automotive care.

Contents

- 1. Understanding the Importance of the OBD2 Port

- 1.1. What is an OBD2 Port?

- 1.2. Why is the OBD2 Port Important?

- 2. Locating the OBD2 Port in a Land Rover Range Rover 4.6 HSE

- 2.1. General Location

- 2.2. Step-by-Step Instructions to Find the OBD2 Port

- 2.3. Visual Aids

- 3. Common Issues and Solutions When Accessing the OBD2 Port

- 3.1. Port is Obstructed

- 3.2. Port is Damaged

- 3.3. Scan Tool Not Connecting

- 4. Utilizing the OBD2 Port for Diagnostics

- 4.1. Basic Diagnostic Procedures

- 4.2. Interpreting Diagnostic Trouble Codes (DTCs)

- 4.3. Advanced Diagnostic Techniques

- 5. Essential Tools for OBD2 Diagnostics

- 5.1. Basic OBD2 Scanners

- 5.2. Advanced Diagnostic Scan Tools

- 5.3. Multimeters

- 5.4. OBD2 Extension Cables

- 6. Common Diagnostic Trouble Codes (DTCs) for Land Rover Range Rover 4.6 HSE

- 6.1. Engine-Related Codes

- 6.2. Transmission-Related Codes

- 6.3. ABS-Related Codes

- 6.4. Air Suspension-Related Codes

- 7. Step-by-Step Diagnostic Guide for Common Issues

- 7.1. Diagnosing a Misfire (P0300)

- 7.2. Diagnosing a Lean Condition (P0171/P0174)

- 7.3. Diagnosing Air Suspension Issues (C1A20)

- 8. Maintenance Tips to Prevent OBD2-Related Issues

- 8.1. Regular Vehicle Inspections

- 8.2. Keeping Your Vehicle Well-Maintained

- 8.3. Addressing Issues Promptly

- 9. Advanced Training and Certification Programs

- 9.1. Automotive Service Excellence (ASE) Certification

- 9.2. Manufacturer-Specific Training

- 9.3. Online Training Resources

- 10. The Future of OBD2 and Automotive Diagnostics

- 10.1. Advancements in OBD2 Technology

- 10.2. Impact on Automotive Technicians

- 10.3. The Role of CAR-DIAGNOSTIC-TOOL.EDU.VN

- 11. Real-World Case Studies

- 11.1. Case Study 1: Diagnosing Intermittent Misfires

- 11.2. Case Study 2: Resolving a Lean Condition

- 11.3. Case Study 3: Fixing Air Suspension Issues

- 12. Conclusion

- 13. FAQs

- 13.1. Where Can I Find the OBD2 Port on My Land Rover Range Rover 4.6 HSE?

- 13.2. What Tools Do I Need to Use the OBD2 Port?

- 13.3. Can I Use Any OBD2 Scanner with My Land Rover Range Rover 4.6 HSE?

- 13.4. What Do I Do if My Scan Tool Isn’t Connecting to the OBD2 Port?

- 13.5. How Do I Interpret Diagnostic Trouble Codes (DTCs)?

- 13.6. What Are Some Common Issues That Can Be Diagnosed Using the OBD2 Port?

- 13.7. How Can I Prevent OBD2-Related Issues?

- 13.8. Where Can I Get Advanced Training in Automotive Diagnostics?

- 13.9. What Are the Latest Advancements in OBD2 Technology?

- 13.10. How Can CAR-DIAGNOSTIC-TOOL.EDU.VN Help Me with My Diagnostic Needs?

1. Understanding the Importance of the OBD2 Port

1.1. What is an OBD2 Port?

An OBD2 (On-Board Diagnostics II) port is a standardized interface used to access a vehicle’s computer system for diagnostics and monitoring. According to the Environmental Protection Agency (EPA), all cars and light trucks manufactured for sale in the United States after January 1, 1996, are required to have an OBD2 system. This standardization ensures that any compliant scan tool can read diagnostic trouble codes (DTCs) and other data, regardless of the vehicle’s make or model.

1.2. Why is the OBD2 Port Important?

The OBD2 port is crucial for several reasons:

- Diagnostics: It allows technicians and vehicle owners to diagnose issues by reading diagnostic trouble codes (DTCs).

- Emissions Testing: It is used to verify that a vehicle is meeting emissions standards.

- Performance Monitoring: It provides real-time data about the engine and other systems, allowing for performance monitoring and tuning.

- Repairs: It aids in identifying the specific components or systems that need repair or replacement.

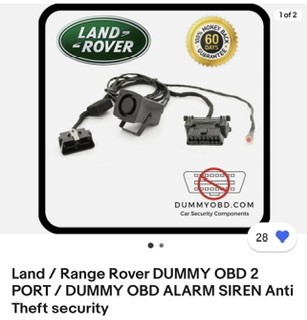

- Security: Modern security systems can use the OBD2 port to monitor vehicle activity and prevent theft, as noted by automotive security experts at Thatcham Research.

For automotive professionals, understanding and utilizing the OBD2 port effectively is a fundamental skill. CAR-DIAGNOSTIC-TOOL.EDU.VN enhances these skills with detailed repair guides, diagnostic tool support, and remote assistance.

2. Locating the OBD2 Port in a Land Rover Range Rover 4.6 HSE

2.1. General Location

In most vehicles, including the Land Rover Range Rover 4.6 HSE, the OBD2 port is typically located inside the cabin. The most common location is beneath the dashboard on the driver’s side. However, the exact placement can vary.

2.2. Step-by-Step Instructions to Find the OBD2 Port

Follow these steps to locate the OBD2 port in your Land Rover Range Rover 4.6 HSE:

- Check Under the Dashboard: Start by looking under the dashboard on the driver’s side. Use a flashlight to get a better view.

- Feel Around: If you don’t see the port immediately, feel around for a rectangular, 16-pin connector.

- Look Near the Steering Column: Sometimes, the port is located near the steering column.

- Consult the Owner’s Manual: If you still can’t find it, consult your vehicle’s owner’s manual for the exact location.

- Check Online Forums: Online forums and communities dedicated to Land Rover vehicles can offer specific advice and images showing the OBD2 port location.

2.3. Visual Aids

Often, a visual aid can be incredibly helpful. Search online for images or videos showing the OBD2 port location in a Range Rover 4.6 HSE. Many online resources provide detailed visual guides.

3. Common Issues and Solutions When Accessing the OBD2 Port

3.1. Port is Obstructed

Sometimes, the OBD2 port may be obstructed by panels or other components.

Solution: Carefully remove any obstructions to gain clear access to the port.

3.2. Port is Damaged

The OBD2 port can sometimes become damaged, preventing proper connection with a scan tool.

Solution: Inspect the port for bent or broken pins. If damaged, the port may need to be replaced. Contact a professional mechanic or CAR-DIAGNOSTIC-TOOL.EDU.VN for guidance.

3.3. Scan Tool Not Connecting

If your scan tool isn’t connecting to the OBD2 port, there could be several reasons:

- Incorrect Tool: Ensure you’re using a scan tool that is compatible with the OBD2 protocol.

- Faulty Connection: Double-check the connection between the scan tool and the OBD2 port.

- Vehicle Issues: The vehicle’s computer system may have issues preventing communication.

Solution: Verify the scan tool’s compatibility, check the connection, and consult a professional if the problem persists.

4. Utilizing the OBD2 Port for Diagnostics

4.1. Basic Diagnostic Procedures

Once you’ve located the OBD2 port, you can use it to perform basic diagnostic procedures:

- Connect the Scan Tool: Plug the scan tool into the OBD2 port.

- Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

- Power On the Scan Tool: Turn on the scan tool and follow the on-screen prompts.

- Read Diagnostic Trouble Codes (DTCs): Use the scan tool to read any stored DTCs.

- Interpret the Codes: Consult a DTC reference guide or online resource to understand what each code means.

4.2. Interpreting Diagnostic Trouble Codes (DTCs)

DTCs are standardized codes that provide information about potential issues with the vehicle. For example, a code like “P0300” indicates a random or multiple cylinder misfire. Each code consists of five characters:

- First Character: Indicates the system (e.g., P for Powertrain, B for Body, C for Chassis, U for Network).

- Second Character: Indicates whether the code is generic (0) or manufacturer-specific (1).

- Third Character: Indicates the specific system or component affected.

- Fourth and Fifth Characters: Provide more specific information about the fault.

Understanding these codes is essential for accurate diagnostics. CAR-DIAGNOSTIC-TOOL.EDU.VN offers detailed guides and support to help you interpret DTCs effectively.

4.3. Advanced Diagnostic Techniques

For more advanced diagnostics, you may need to use a more sophisticated scan tool that can perform functions like:

- Live Data Streaming: View real-time data from various sensors and systems.

- Actuator Testing: Activate specific components to verify their functionality.

- Freeze Frame Data: View the data that was recorded when the DTC was set.

These advanced techniques can provide valuable insights into the operation of the vehicle.

5. Essential Tools for OBD2 Diagnostics

5.1. Basic OBD2 Scanners

A basic OBD2 scanner is an essential tool for any car owner or technician. These scanners can read and clear DTCs, providing a quick and easy way to diagnose common issues.

Examples:

- Autel AutoLink AL319: A popular entry-level scanner that is easy to use and provides basic diagnostic functions.

- Innova 3100i: Offers additional features like battery and charging system testing.

5.2. Advanced Diagnostic Scan Tools

For more in-depth diagnostics, an advanced scan tool is necessary. These tools offer a wider range of functions, including live data streaming, actuator testing, and advanced coding capabilities.

Examples:

| Tool | Features | Benefits |

|---|---|---|

| Autel MaxiSys MS906BT | Live data, bi-directional control, key coding, ECU programming. | Comprehensive diagnostics, advanced repairs, and customization options. |

| Launch X431 V+ | Full system diagnostics, special functions, remote diagnostics. | Wide vehicle coverage, advanced troubleshooting capabilities, and remote support for complex issues. |

| Snap-on Zeus | Intelligent diagnostics, guided component tests, integrated scope and multimeter. | Streamlined workflow, accurate diagnosis, and efficient repairs. |

| Thinkcar Thinktool Pro+ | All system diagnosis, 35+ reset functions, online programming, and coding. | Comprehensive vehicle health analysis, advanced repair capabilities, and access to up-to-date vehicle software. |

| BlueDriver Pro | Wireless Bluetooth, full system scans, advanced features via mobile app. | Convenient wireless connectivity, comprehensive diagnostics, and user-friendly interface. |

5.3. Multimeters

A multimeter is a versatile tool that can be used to measure voltage, current, and resistance. It is essential for diagnosing electrical issues in a vehicle.

Examples:

- Fluke 115: A reliable and accurate multimeter suitable for automotive use.

- Klein Tools MM400: A durable and affordable multimeter with a range of useful features.

5.4. OBD2 Extension Cables

An OBD2 extension cable can be useful if the OBD2 port is in a difficult-to-reach location.

Benefits:

- Convenience: Makes it easier to connect a scan tool without straining or damaging the port.

- Flexibility: Allows you to position the scan tool in a more convenient location while performing diagnostics.

6. Common Diagnostic Trouble Codes (DTCs) for Land Rover Range Rover 4.6 HSE

6.1. Engine-Related Codes

Common engine-related DTCs for the Land Rover Range Rover 4.6 HSE include:

- P0300: Random/Multiple Cylinder Misfire Detected.

- P0171/P0174: System Too Lean (Bank 1/Bank 2).

- P0130/P0150: O2 Sensor Circuit Malfunction (Bank 1 Sensor 1/Bank 2 Sensor 1).

- P0113: Intake Air Temperature Sensor Circuit High Input.

- P0102: Mass Air Flow (MAF) Sensor Circuit Low Input.

These codes can indicate a variety of issues, from faulty sensors to vacuum leaks.

6.2. Transmission-Related Codes

Transmission-related DTCs may include:

- P0730: Incorrect Gear Ratio.

- P0722: Output Speed Sensor Circuit No Signal.

- P0740: Torque Converter Clutch Circuit Malfunction.

These codes can point to problems with the transmission itself or related sensors and solenoids.

6.3. ABS-Related Codes

ABS-related DTCs may include:

- C1000: ABS Control Module Fault.

- C1145: Wheel Speed Sensor Circuit Fault.

These codes can indicate issues with the ABS control module or wheel speed sensors.

6.4. Air Suspension-Related Codes

Given the Range Rover’s air suspension system, common codes include:

- C1A20: Pressure Increases Too Slow When Filling Reservoir.

- C1A13: Pressure Not Decreasing When Venting Reservoir.

- C1A03: Front Right Height Sensor Circuit Fault.

These codes often relate to issues with the air compressor, valve block, or height sensors.

7. Step-by-Step Diagnostic Guide for Common Issues

7.1. Diagnosing a Misfire (P0300)

A misfire can be caused by a variety of factors. Here’s a step-by-step guide to diagnosing a P0300 code:

- Check for Other Codes: Read all DTCs to see if any other codes are present. Address those first, as they may be related.

- Inspect Spark Plugs: Remove and inspect the spark plugs for wear, damage, or fouling. Replace as needed.

- Check Ignition Coils: Test the ignition coils using a multimeter to ensure they are functioning properly.

- Check Fuel Injectors: Use a stethoscope to listen to each fuel injector and ensure they are clicking. If not, they may be clogged or faulty.

- Check for Vacuum Leaks: Inspect vacuum lines and intake manifold for leaks. Use a smoke tester to identify any leaks.

- Compression Test: Perform a compression test to check the mechanical condition of the engine.

7.2. Diagnosing a Lean Condition (P0171/P0174)

A lean condition can be caused by vacuum leaks, faulty sensors, or fuel delivery issues. Follow these steps to diagnose a P0171 or P0174 code:

- Check for Vacuum Leaks: Inspect all vacuum lines and intake manifold for leaks.

- Inspect MAF Sensor: Clean the MAF sensor and check its readings using a scan tool. Replace if necessary.

- Check Fuel Pressure: Use a fuel pressure gauge to check the fuel pressure at the fuel rail.

- Inspect O2 Sensors: Check the O2 sensors for proper operation using a scan tool.

7.3. Diagnosing Air Suspension Issues (C1A20)

Air suspension issues can be tricky to diagnose. Here’s a step-by-step guide to diagnosing a C1A20 code:

- Check Air Compressor: Inspect the air compressor for proper operation. Listen for unusual noises and check its output pressure.

- Inspect Valve Block: Check the valve block for leaks or malfunctions.

- Check Air Lines: Inspect all air lines for leaks or damage.

- Check Height Sensors: Verify that the height sensors are functioning properly and providing accurate readings.

8. Maintenance Tips to Prevent OBD2-Related Issues

8.1. Regular Vehicle Inspections

Performing regular vehicle inspections can help identify potential issues before they trigger DTCs. Check fluids, inspect belts and hoses, and look for any signs of wear or damage.

8.2. Keeping Your Vehicle Well-Maintained

Following the manufacturer’s recommended maintenance schedule is crucial for preventing OBD2-related issues. This includes regular oil changes, spark plug replacements, and filter replacements.

8.3. Addressing Issues Promptly

Addressing issues promptly can prevent them from escalating and triggering more severe DTCs. If you notice any unusual symptoms, such as a rough idle or decreased fuel economy, have your vehicle inspected by a qualified technician.

9. Advanced Training and Certification Programs

9.1. Automotive Service Excellence (ASE) Certification

ASE certification is a widely recognized standard for automotive technicians. Earning ASE certification demonstrates your knowledge and skills in specific areas of automotive repair.

Benefits:

- Increased Credibility: ASE certification enhances your credibility and reputation as a qualified technician.

- Career Advancement: It can lead to better job opportunities and higher pay.

- Professional Development: It helps you stay up-to-date with the latest automotive technologies and repair techniques.

9.2. Manufacturer-Specific Training

Many manufacturers, including Land Rover, offer specialized training programs for their vehicles. These programs provide in-depth knowledge of the vehicle’s systems and components.

Benefits:

- Expert Knowledge: Gain expert knowledge of specific vehicle models and systems.

- Access to Resources: Access to manufacturer-specific diagnostic tools and repair information.

- Improved Diagnostic Skills: Enhanced diagnostic skills for complex issues.

9.3. Online Training Resources

Numerous online training resources are available for automotive technicians. These resources offer a flexible and convenient way to enhance your skills and knowledge.

Examples:

- CAR-DIAGNOSTIC-TOOL.EDU.VN: Offers a range of online courses and training materials for automotive diagnostics and repair.

- Coursera and Udemy: Provide a variety of automotive-related courses taught by industry experts.

10. The Future of OBD2 and Automotive Diagnostics

10.1. Advancements in OBD2 Technology

OBD2 technology is constantly evolving. Newer vehicles are equipped with more sophisticated systems that provide more detailed diagnostic information.

Key Trends:

- OBD3: The next generation of OBD systems is expected to provide even more comprehensive monitoring and reporting capabilities.

- Wireless Connectivity: Wireless OBD2 adapters and scan tools are becoming increasingly popular, allowing for remote diagnostics and data logging.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms are emerging, providing access to vast databases of repair information and diagnostic support.

10.2. Impact on Automotive Technicians

These advancements will have a significant impact on automotive technicians. Technicians will need to stay up-to-date with the latest technologies and repair techniques to effectively diagnose and repair modern vehicles.

10.3. The Role of CAR-DIAGNOSTIC-TOOL.EDU.VN

CAR-DIAGNOSTIC-TOOL.EDU.VN is committed to providing automotive technicians with the resources and training they need to succeed in this evolving industry. Our comprehensive diagnostic tools, repair guides, and remote assistance services are designed to help you diagnose and repair vehicles efficiently and effectively.

11. Real-World Case Studies

11.1. Case Study 1: Diagnosing Intermittent Misfires

Scenario: A Land Rover Range Rover 4.6 HSE owner reports intermittent misfires and a P0300 code.

Diagnostic Steps:

- Initial Scan: Read DTCs and found P0300 (Random/Multiple Cylinder Misfire Detected).

- Spark Plug Inspection: Inspected spark plugs and found signs of wear. Replaced all spark plugs.

- Ignition Coil Testing: Tested ignition coils using a multimeter. Found one faulty coil and replaced it.

- Fuel Injector Check: Checked fuel injectors using a stethoscope. All injectors were clicking.

- Vacuum Leak Check: Inspected vacuum lines and intake manifold for leaks. Found a loose vacuum line and secured it.

- Test Drive: Performed a test drive and confirmed that the misfires were resolved.

Outcome: The intermittent misfires were resolved by replacing the spark plugs and faulty ignition coil and securing the loose vacuum line.

11.2. Case Study 2: Resolving a Lean Condition

Scenario: A Land Rover Range Rover 4.6 HSE owner reports poor fuel economy and a P0171 code.

Diagnostic Steps:

- Initial Scan: Read DTCs and found P0171 (System Too Lean – Bank 1).

- Vacuum Leak Check: Inspected vacuum lines and intake manifold for leaks. Found a cracked vacuum line and replaced it.

- MAF Sensor Inspection: Cleaned the MAF sensor and checked its readings using a scan tool. The MAF sensor was reading low. Replaced the MAF sensor.

- Fuel Pressure Check: Checked fuel pressure at the fuel rail. Fuel pressure was within specifications.

- O2 Sensor Check: Checked the O2 sensors for proper operation using a scan tool. The O2 sensors were functioning properly.

- Test Drive: Performed a test drive and confirmed that the fuel economy had improved.

Outcome: The lean condition was resolved by replacing the cracked vacuum line and the faulty MAF sensor.

11.3. Case Study 3: Fixing Air Suspension Issues

Scenario: A Land Rover Range Rover 4.6 HSE owner reports that the air suspension is not working properly and a C1A20 code is present.

Diagnostic Steps:

- Initial Scan: Read DTCs and found C1A20 (Pressure Increases Too Slow When Filling Reservoir).

- Air Compressor Inspection: Inspected the air compressor for proper operation. Found that the compressor was running but producing low pressure.

- Valve Block Inspection: Checked the valve block for leaks. Found minor leaks and replaced the valve block.

- Air Line Inspection: Inspected all air lines for leaks. No leaks were found.

- Height Sensor Check: Verified that the height sensors were functioning properly. The height sensors were accurate.

- Replaced Air Compressor: Due to low pressure output, the air compressor was replaced.

- System Test: Ran the air suspension system to ensure proper functionality.

Outcome: The air suspension issues were resolved by replacing the faulty air compressor and valve block.

12. Conclusion

Understanding the OBD2 port location and how to use it is essential for diagnosing and repairing modern vehicles like the Land Rover Range Rover 4.6 HSE. By following the steps and tips outlined in this guide, you can effectively diagnose and resolve common issues, keeping your vehicle running smoothly. CAR-DIAGNOSTIC-TOOL.EDU.VN is dedicated to providing you with the tools, resources, and training you need to excel in the automotive industry.

Are you facing diagnostic challenges or seeking to enhance your technical skills? Contact CAR-DIAGNOSTIC-TOOL.EDU.VN today via WhatsApp at +1 (641) 206-8880 or visit our office at 1100 Congress Ave, Austin, TX 78701, United States. Let us help you elevate your automotive expertise with our comprehensive solutions, including advanced repair guides, diagnostic tool support, remote assistance, and specialized technician training. Explore our website at CAR-DIAGNOSTIC-TOOL.EDU.VN and discover how we can support your journey to becoming a proficient automotive technician.

Land Rover Range Rover 4.6 HSE Engine Compartment Overview

Land Rover Range Rover 4.6 HSE Engine Compartment Overview

13. FAQs

13.1. Where Can I Find the OBD2 Port on My Land Rover Range Rover 4.6 HSE?

The OBD2 port is typically located under the dashboard on the driver’s side. Use a flashlight to help locate it.

13.2. What Tools Do I Need to Use the OBD2 Port?

You will need an OBD2 scanner or scan tool to read diagnostic trouble codes (DTCs) and access vehicle data.

13.3. Can I Use Any OBD2 Scanner with My Land Rover Range Rover 4.6 HSE?

Yes, any OBD2-compliant scanner should work with your Land Rover Range Rover 4.6 HSE. However, advanced functions may require a more sophisticated scan tool.

13.4. What Do I Do if My Scan Tool Isn’t Connecting to the OBD2 Port?

Check the connection, ensure the scan tool is compatible, and verify that the vehicle’s ignition is turned on. If the problem persists, consult a professional.

13.5. How Do I Interpret Diagnostic Trouble Codes (DTCs)?

Consult a DTC reference guide or online resource to understand what each code means. CAR-DIAGNOSTIC-TOOL.EDU.VN provides detailed guides and support for interpreting DTCs.

13.6. What Are Some Common Issues That Can Be Diagnosed Using the OBD2 Port?

Common issues include engine misfires, lean conditions, transmission problems, and ABS faults.

13.7. How Can I Prevent OBD2-Related Issues?

Perform regular vehicle inspections, follow the manufacturer’s recommended maintenance schedule, and address issues promptly.

13.8. Where Can I Get Advanced Training in Automotive Diagnostics?

CAR-DIAGNOSTIC-TOOL.EDU.VN offers a range of online courses and training materials for automotive diagnostics and repair. Additionally, consider pursuing ASE certification or manufacturer-specific training.

13.9. What Are the Latest Advancements in OBD2 Technology?

Key trends include OBD3, wireless connectivity, and cloud-based diagnostics.

13.10. How Can CAR-DIAGNOSTIC-TOOL.EDU.VN Help Me with My Diagnostic Needs?

CAR-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive diagnostic tools, repair guides, and remote assistance services to help you diagnose and repair vehicles efficiently and effectively. Contact us today to learn more.